A car door sill side beam

An edge beam and threshold technology, applied in the field of auto parts, can solve the problems of splicing together and assembly difficulty, and achieve the effect of reducing assembly difficulty, reducing welding sealant dripping, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

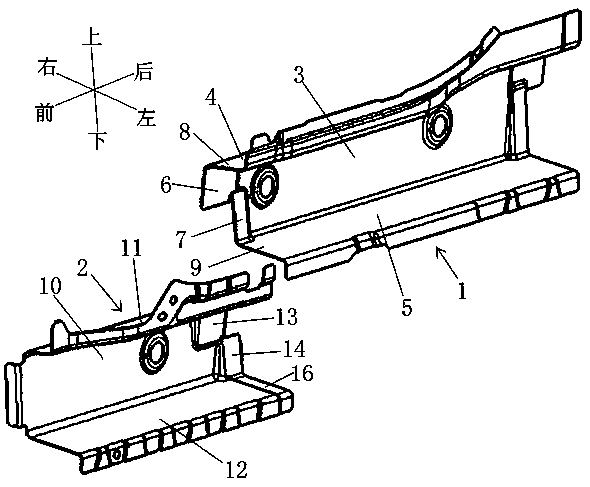

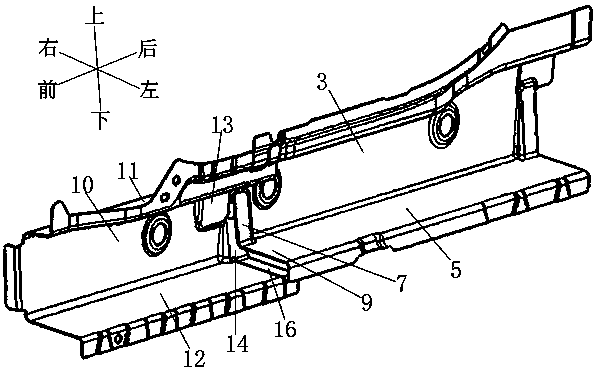

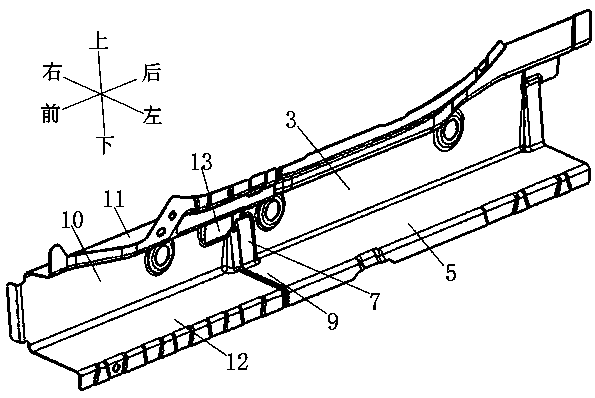

[0022] The present invention will be further described below in conjunction with accompanying drawing.

[0023] Such as Figure 1 to Figure 6 A vehicle door sill side beam shown includes a U-shaped beam rear section 1 and a front section 2 of the side beam, the rear section 1 of the side beam and the front section 2 of the side beam are sheet metal parts, and the rear section 1 of the side beam It includes a first bottom wall 3 extending in the front-rear direction, a first upper side wall 4 extending leftward from the upper edge of the first bottom wall 3 , and a first lower side wall extending leftward from the lower edge of the first bottom wall 3 5. The front end of the upper half of the first bottom wall 3 is a first overlapping portion 6 protruding forward from the front end of the lower half of the first bottom wall 3, and the first overlapping portion 6 is directed from bottom to top. Tilting to the left, the front end of the lower half of the first bottom wall 3 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com