A treatment method for pvc dust

A dust treatment and material port technology, applied in the field of environmental protection treatment facilities, can solve the problems of dust leakage pollution, raw material leakage, etc., and achieve the effect of eliminating resin dust, ensuring sealing performance, and solving the problem of sealing leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

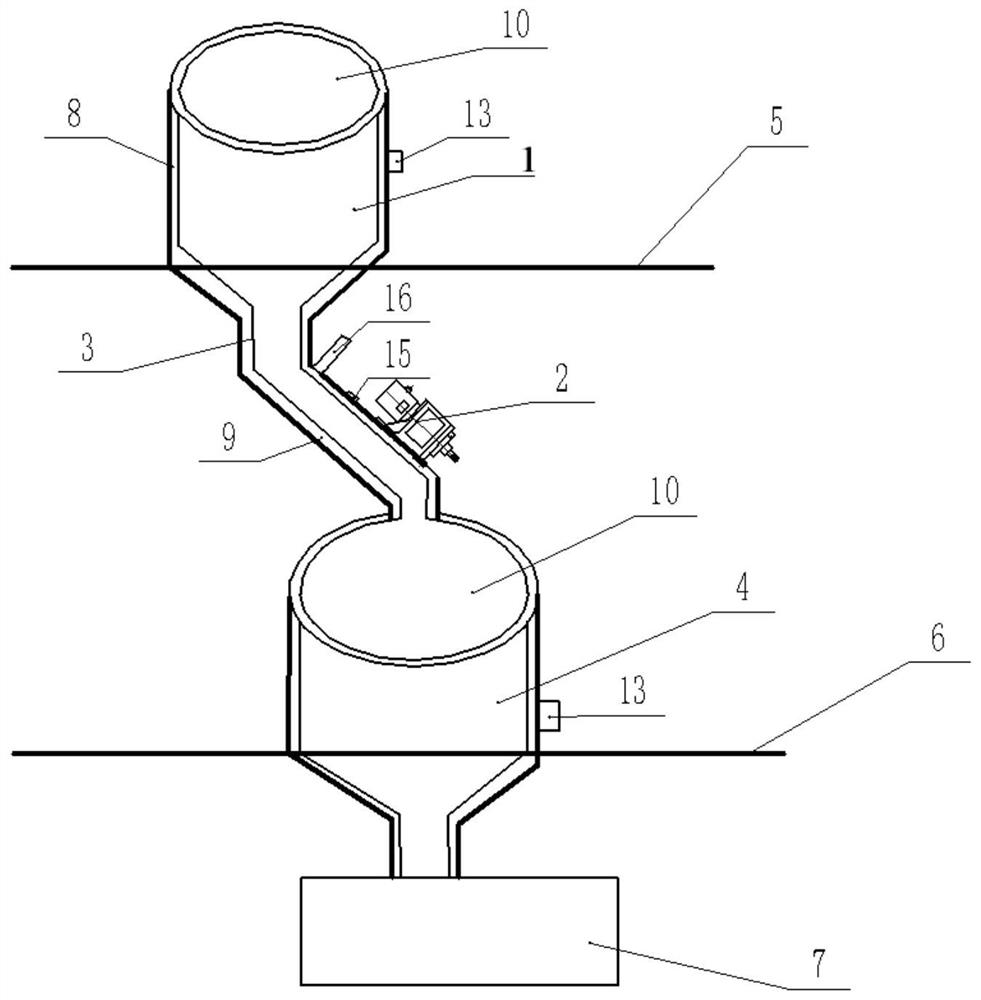

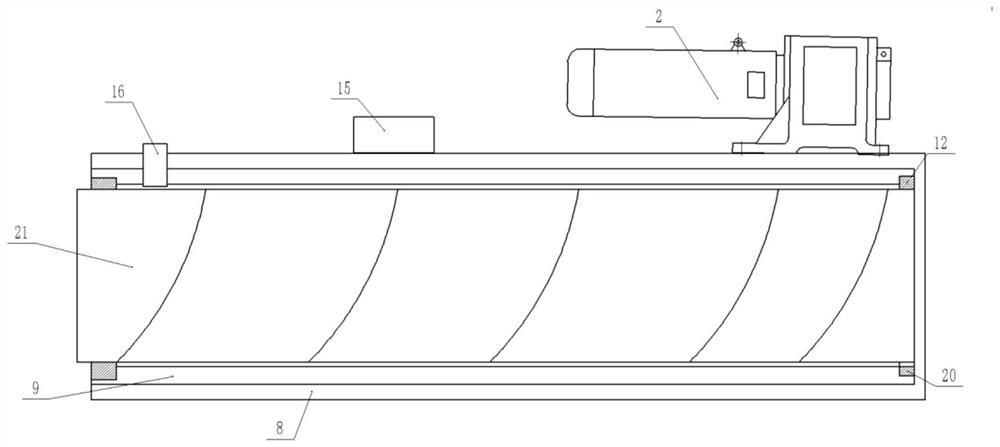

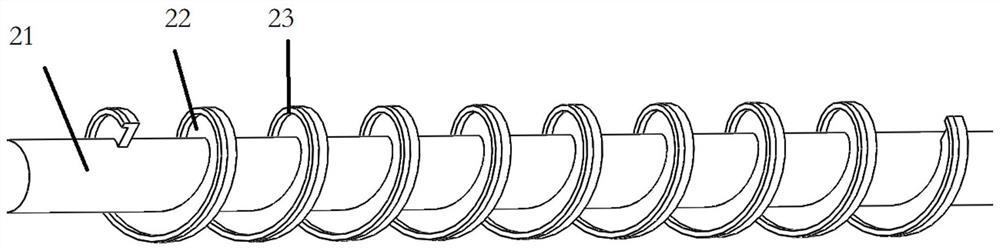

[0017] A method for treating PVC dust, characterized in that it includes: a first-level platform 5, a conveyor 2, a second-level platform 6, processing equipment 7, pipelines 3, a first feeding port 1, a second feeding port 4, and a feeding port Rod 21, sealing layer 8, sleeve 9, baffle plate 10, controller 13, sealing ring 12, sensor 15, air inlet 16, feeding rod 21, spiral groove 22, deflector 23, first-level platform 5 is provided with a first discharge port 1, and the second discharge port 4 is located on the secondary platform 6 directly below the first discharge port 1, and the vertical drop between the primary platform 5 and the secondary platform 6 is three m; the first feeding port 1 and the second feeding port 4 are provided with a controller 13; the lower end of the first feeding port 1 is vertically provided with a pipeline 3, and the pipeline 3 passes between the second feeding port 4 The sleeve 9 is connected, and the sleeve 9 is provided with an inductor 15, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com