Lamp and lighting control method thereof

A lighting control and lamp technology, applied in the field of lighting, can solve the problems of step difference, uneven connection of thick-walled units, direct bright spots, etc., and achieve the effect of good lighting uniformity, saving lighting space, and lighting uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

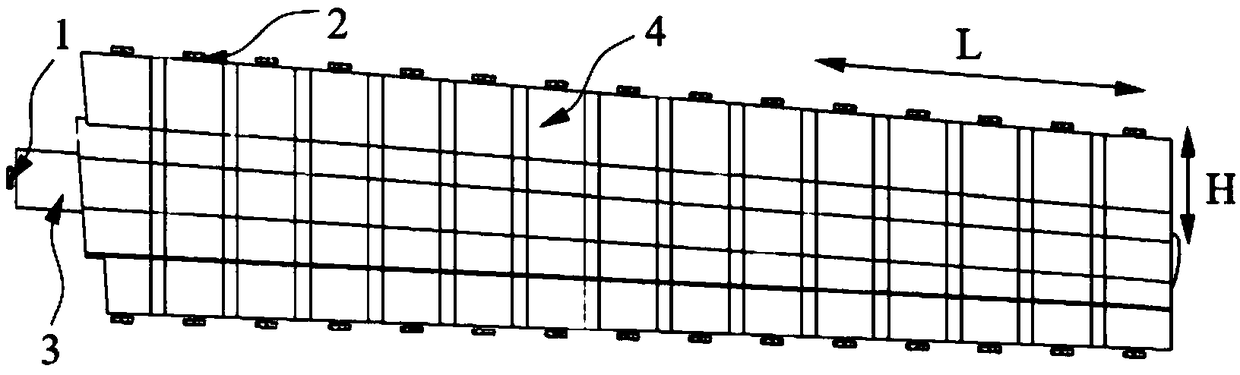

[0033] Such as figure 1 and figure 2 As shown, the present embodiment provides a lamp, which includes a photoconductor 3 and a light guide element 4 with a thickness in the range of 2mm-5mm. The photoconductor 3 preferably adopts a cylindrical structure. The first light source group 1 and the second light source group 2 arranged on the light guide element 4, wherein the first light source group 1 is located in the length direction of the photoconductor 3 ( figure 1 Each first light source group 1 includes at least one light source. In this embodiment, the above-mentioned first light source group 1 is located at one end of the length direction of the photoconductor 3 and includes only one light source. The distance between the first light source group 1 and the photoconductor 3 is very short, about 0.5 mm; The light-emitting surface on the front side of the light element 4 emits light.

[0034] The number of photoconductors 3 is not limited to the one in this embodiment. If...

Embodiment 2

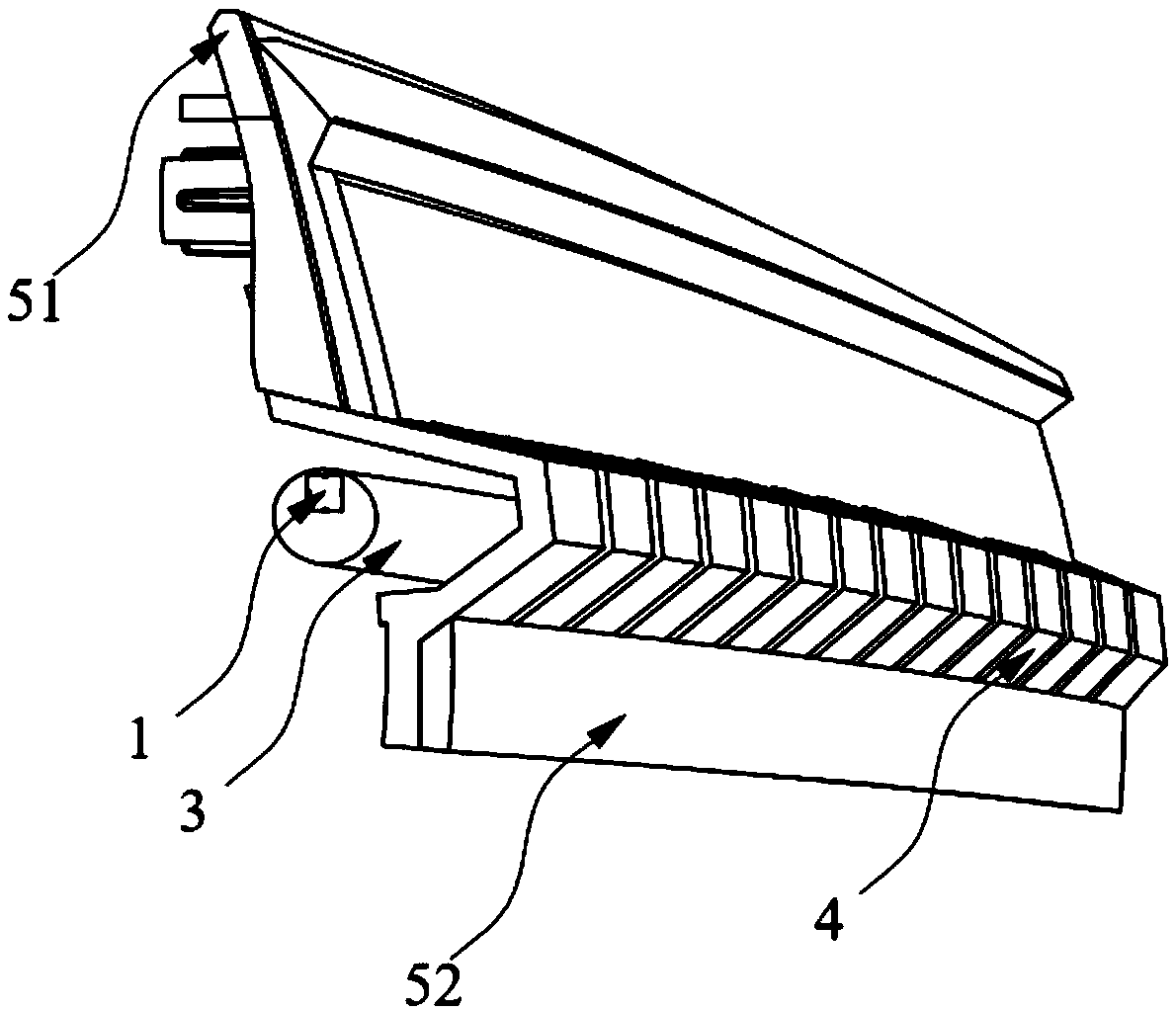

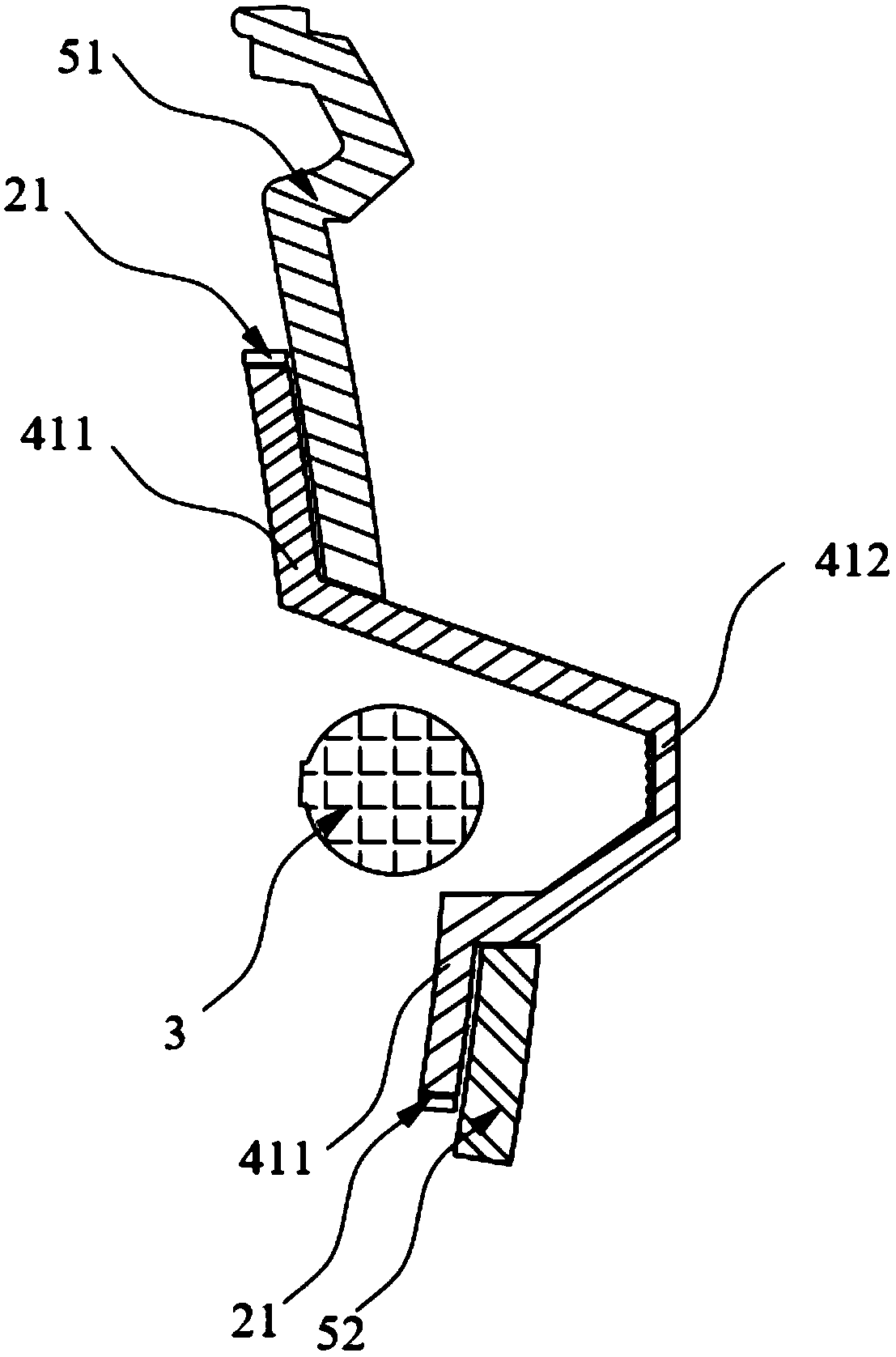

[0047] The difference between this embodiment and the first embodiment lies in that the structure of the optical element is different, and the positional relationship between the light guide 3 and the light guide element 4 is different. Specifically, such as Figure 7 As shown, the lamp in this embodiment includes a photoconductor 3, a first light source group 1, a second light source group 2, and a light guide element 4 with a thickness in the range of 2mm-5mm. The first light source group in this embodiment 1 is located in the length direction of the photoconductor 3 ( Figure 6 L direction shown in ) and includes only one light source, the distance between the first light source group 1 and the photoconductor 3 is very short, about 0.5 mm. The light guide element 4 in this embodiment is closed, and a through hole is provided in it, and an incident surface is provided on its rear side, and the incident surface forms a placement groove, wherein the second light source group ...

Embodiment 3

[0052] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that in this embodiment, the light guide element 4 is made of a material with scattering properties or its longitudinal section adopts a second optical pattern of other shapes.

[0053] Such as Figure 6 As shown, the longitudinal section of the first optical pattern on the light guide 3 is arranged in a triangle, and the light guide element 4 is made of a material with scattering properties, which may be polycarbonate or the like. Figure 6 The shadow part of the light guide element 4 is opaque, the purpose is to prevent the light rays of the second light source group 2 from crossing each other when propagating in the light guide element 4, resulting in uneven luminescence, and improving the heat dissipation characteristics of the light guide element 4, Make it glow more evenly.

[0054] Such as Figure 7 As shown, the longitudinal section of the first optical pattern on the light guide 3 ado...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com