Light-emitting diode (LED) lamp and producing method thereof

A technology of light-emitting diodes and lamps, which is applied to semiconductor devices, light sources, electric light sources, etc. of light-emitting elements, can solve the problems of low luminous efficiency, hurt people, increase the amount of earth material, etc., and achieve high light utilization efficiency and good luminous uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

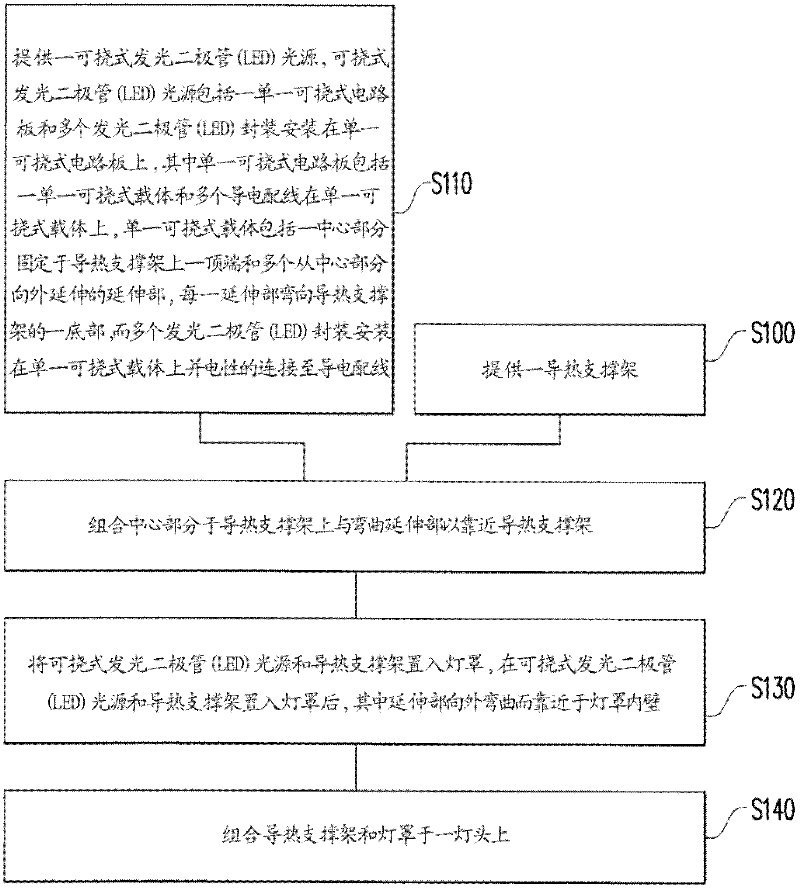

[0051] image 3 It is a flowchart of a manufacturing method of a light emitting diode (LED) lamp according to an embodiment of the present invention. Please refer to image 3, the manufacturing method of the light-emitting diode (LED) lamp of the present embodiment includes: providing a heat-conducting support frame (step S100); providing a flexible light-emitting diode (LED) light source, the flexible light-emitting diode (LED) light source comprising a single A flexible circuit board and multiple light-emitting diode (LED) packages are mounted on a single flexible circuit board, wherein the single flexible circuit board includes a single flexible carrier and multiple conductive wires on the single flexible carrier Above, a single flexible carrier includes a central part fixed on a top end of the thermally conductive support frame and a plurality of extensions extending outward from the central part, each extension bends a bottom of the thermally conductive support frame, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com