Light emitting diode source and manufacturing method thereof and backlight source with light emitting diode source

A technology of light-emitting diodes and backlights, which is applied in the field of backlights and backlights of liquid crystal display devices. It can solve the problems of long optical path, insufficient light intensity, and poor uniformity, and achieve the effect of good uniformity of light emission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

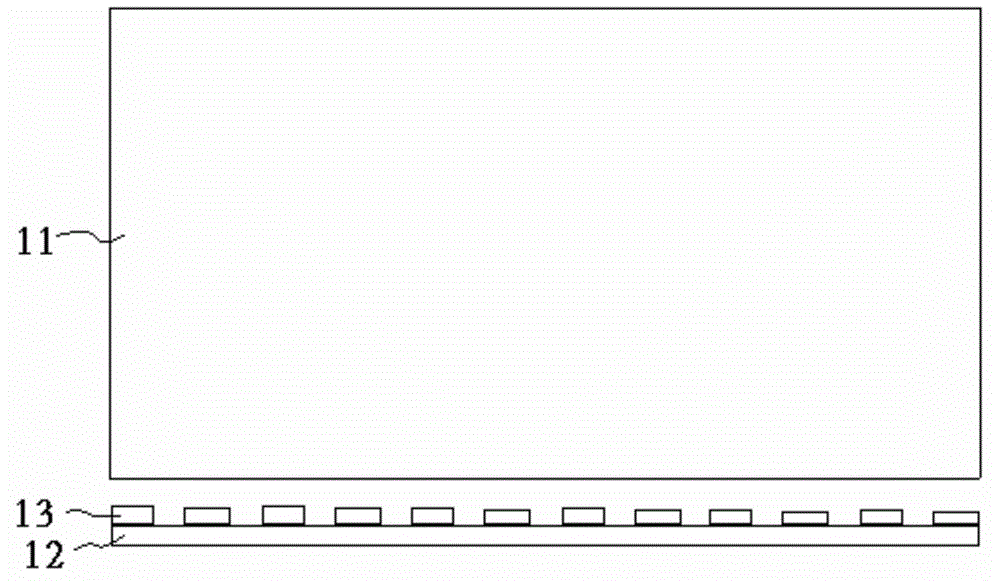

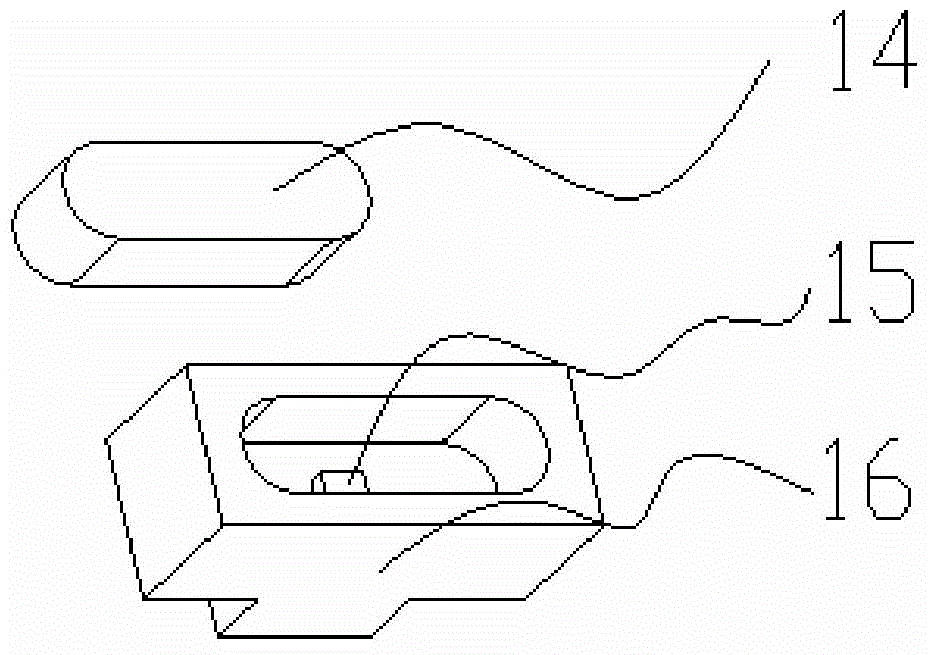

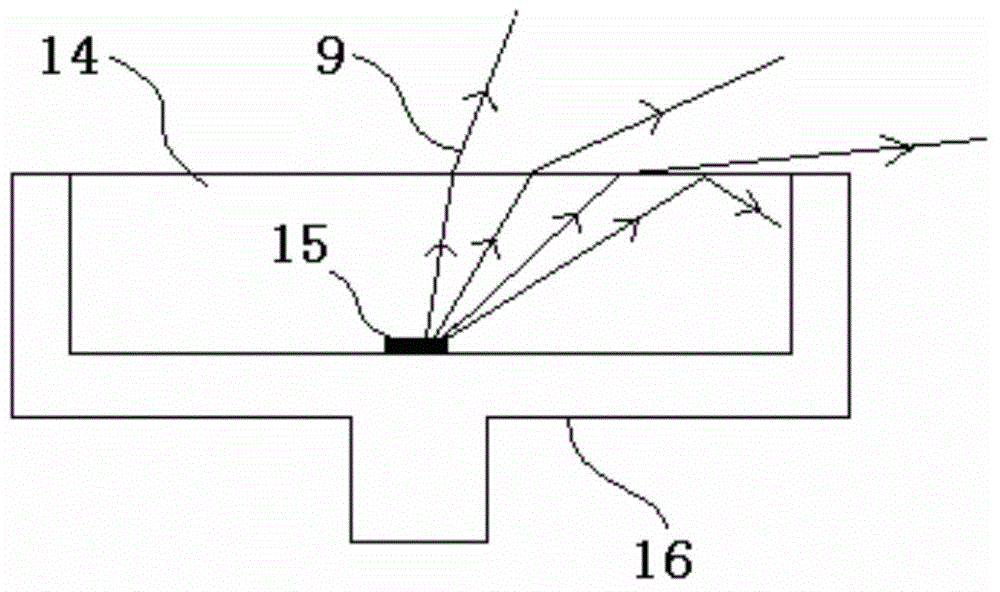

[0048] An embodiment of the present invention provides a light emitting diode light source, such as Figure 5 with Image 6 As shown, it includes: an elongated light-emitting cup 16; a light-emitting diode light-emitting chip 15 arranged at the bottom of the light-emitting cup 16; member 14; a light uniform sheet 17 made of polyethylene on the upper surface of the encapsulation member 14.

[0049] The light uniform sheet 17 has a thickness of 0.1-0.2 mm, and its upper surface has a plurality of triangular prism structures (light uniform structures) 81 on both sides along its length direction (that is, the length direction of the LED light source). These triangular prism structures 81 Arranged side by side perpendicular to the length direction, the bottom of each triangular prism structure 81 is downward and connected to the upper surface of the light uniform sheet 17, and the apex opposite to the bottom is upward.

[0050]Preferably, among the triangular prism structures 81 ...

Embodiment 2

[0053] An embodiment of the present invention provides a light emitting diode light source, such as Figure 8 As shown, it has a structure similar to that of the LED light source in Embodiment 1. The difference is that there is no light uniform sheet 17 , and the above-mentioned triangular prism structure 81 is directly located on the upper surface of the package 14 at both sides along the length direction.

Embodiment 3

[0055] An embodiment of the present invention provides a light emitting diode light source, such as Figure 9 , Figure 10 , Figure 11 As shown, it has a structure similar to that of the LED light source in Embodiment 1. The difference is that there is no triangular prism structure on the upper surface of the light uniform sheet along the length direction, but has a light uniform surface (light uniform structure) 82, and the light uniform surface 82 is inclined downward from the middle to the side along the length direction. Specifically, the light uniform surface 82 can be a plane (such as Figure 9 shown), convex (such as Figure 10 shown), concave (such as Figure 11 Shown) and other forms (such as the combination of various surfaces).

[0056] The light uniform surface 82 acts as the right side of the right triangular prism structure 81 in the first embodiment, thereby improving the light uniformity and overall brightness of the LED light source. However, in order t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com