Simple agricultural rammer compactor

A rammer, agricultural technology, applied in agricultural machinery and implements, application, agriculture, etc., can solve the problems of heavy motor burden, inconvenient use, inconvenient use, etc., to achieve low cost, avoid discomfort, and facilitate promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

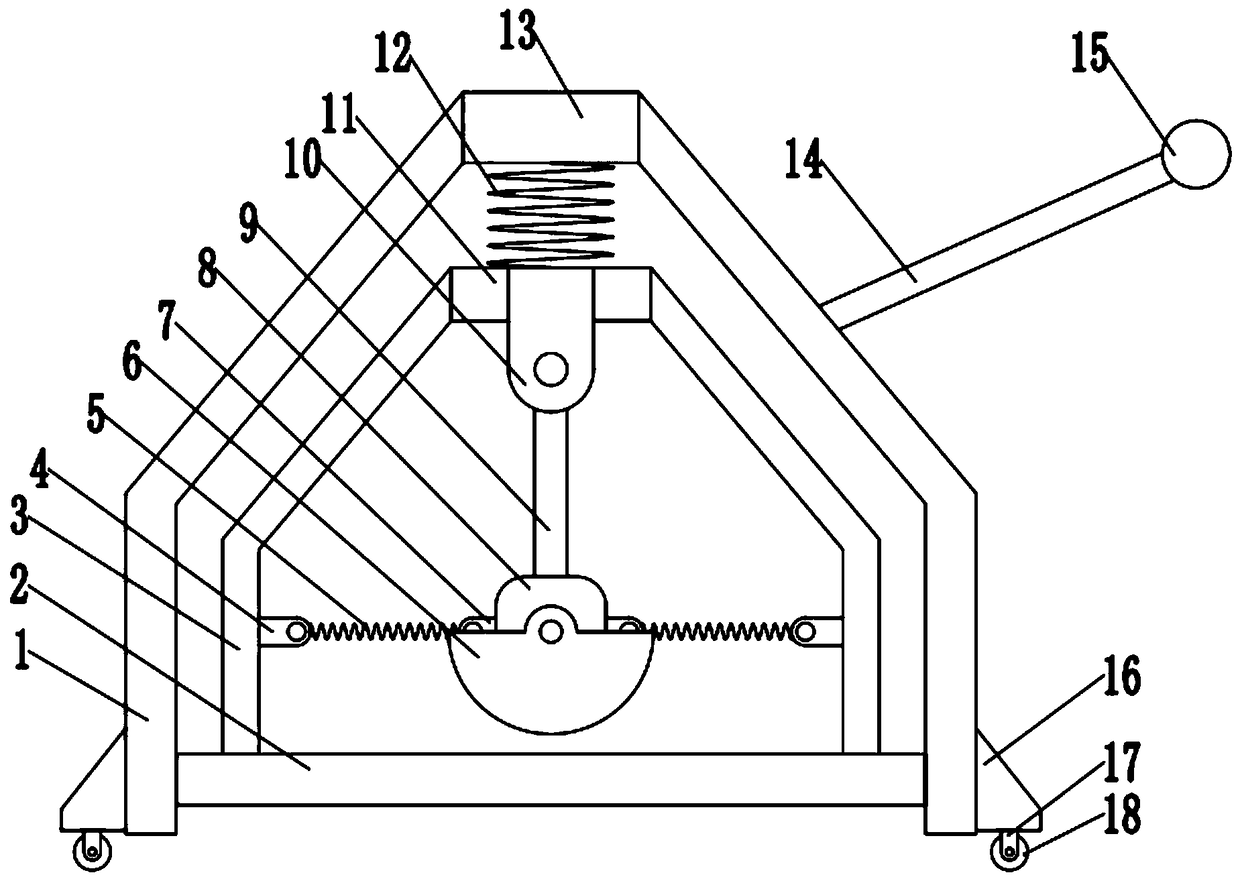

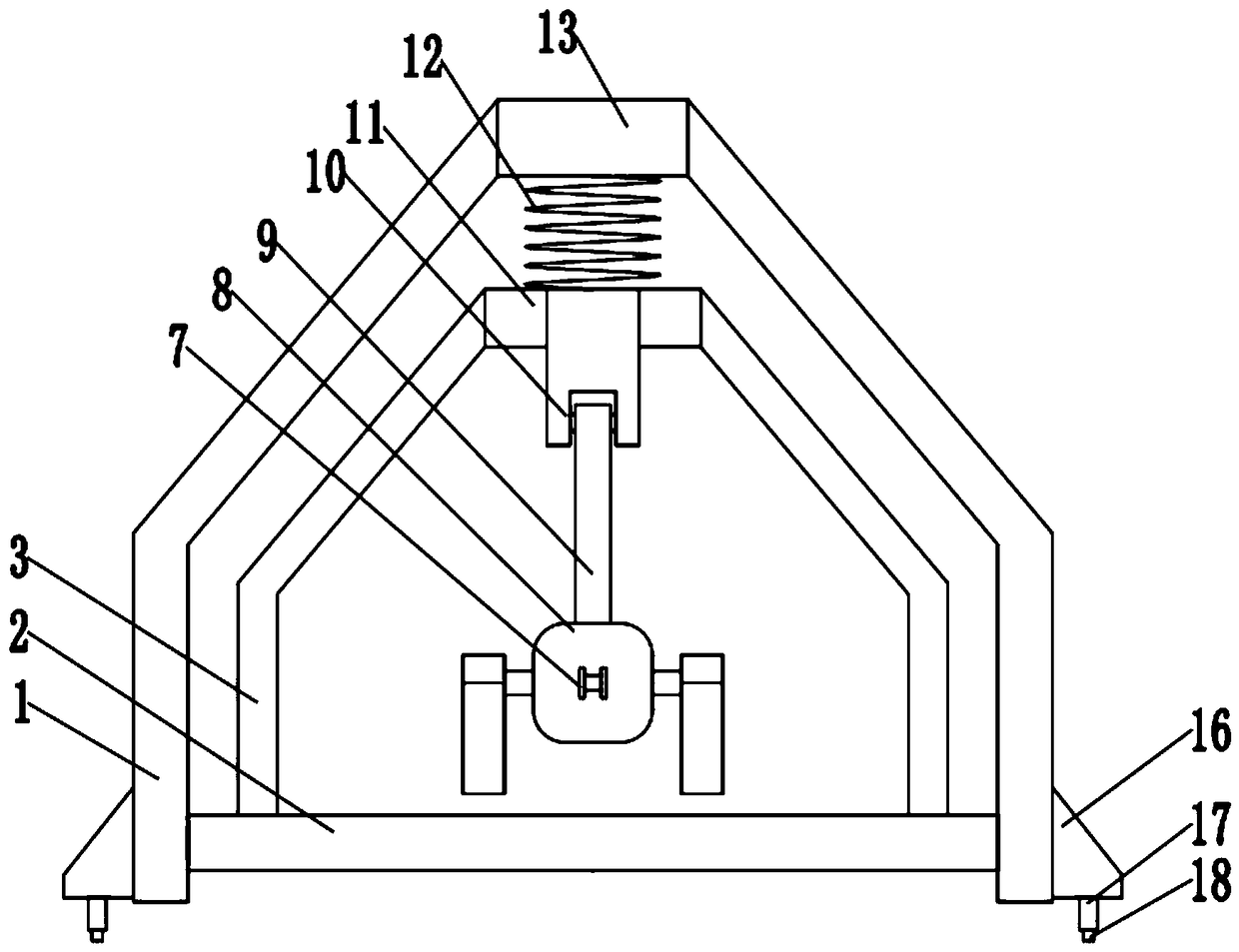

[0022] see figure 1 and figure 2 , a simple agricultural ramming machine, comprising an outer frame 1, an inner frame 3 is arranged inside the outer frame 1, the bottom of the inner frame 3 is fixedly connected to a tamping plate 2, the tamping plate 2 is slidably connected to the inner side of the outer frame 1, and the top of the outer frame 1 The outer top seat 13 is fixedly connected, and the bottom of the outer top seat 13 is fixedly connected with the second spring 12, so as to prevent the outer frame 1 from moving together when the inner frame 3 moves, and the bottom of the second spring 12 is fixedly connected with the inner top seat 11, and the inner top seat 11 is fixedly connected To the inner frame 3, the outer side of the inner top seat 11 is fixedly connected to the third connecting seat 10, and the third connecting seat 10 is rotated to connect to the connecting rod 9, the bottom of the connecting rod 9 is fixedly connected to the double-headed motor 8, and the...

Embodiment 2

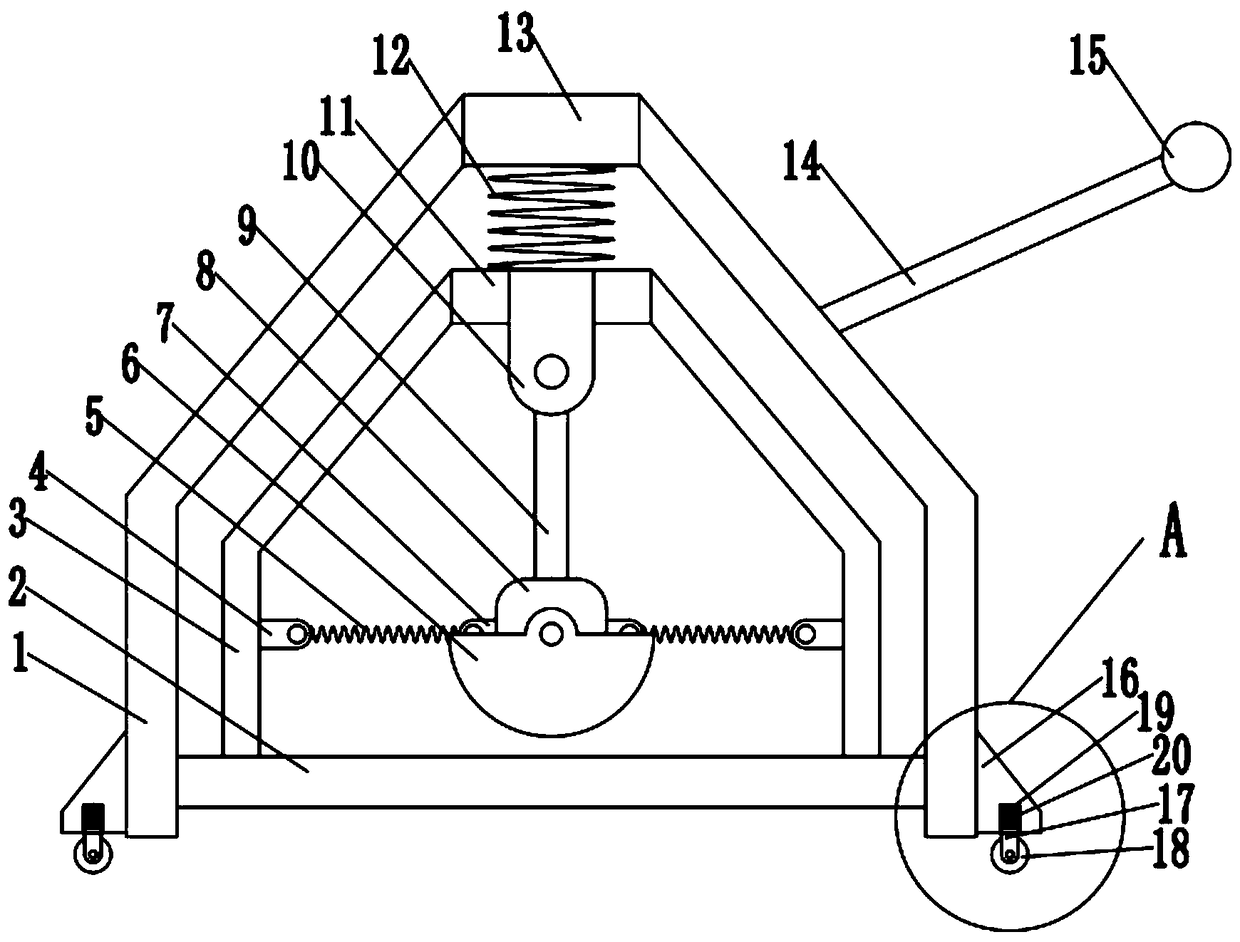

[0024] see image 3 and Figure 4 , this embodiment is improved on the basis of Embodiment 1. A groove 19 is provided in the roller seat 16, and the third spring 20 is fixedly connected in the groove 19, and the bottom of the third spring 20 is connected to the roller frame 17. During the tamping operation, the tamping plate 2 drives the inner frame 3 to move vertically, and the third spring 20 effectively slows down the vibration of the outer frame 1 to avoid causing discomfort to the user.

[0025] In the present invention, when in use, push the device to the position where ramming is required, turn on the double-head motor 8, and drive the eccentric wheels 8 on both sides to rotate. Since the two eccentric wheels 8 are in the same position and the relative angle is zero, the double-head motor 8 makes regular reciprocating motions in the moving surface, and under the action of the first spring 5, the force in the horizontal direction generated by the rotation of the eccentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com