Antiroll torsion bar fatigue test device and method

An anti-roll torsion bar and fatigue test technology, which is applied in the field of anti-roll torsion bar fatigue test equipment, achieves the effects of small test resources, simple structure, and improved fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

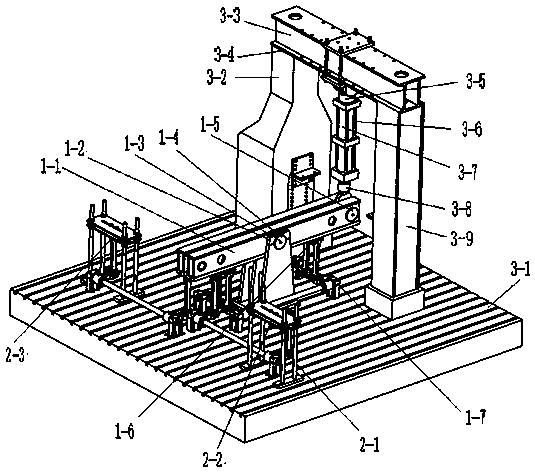

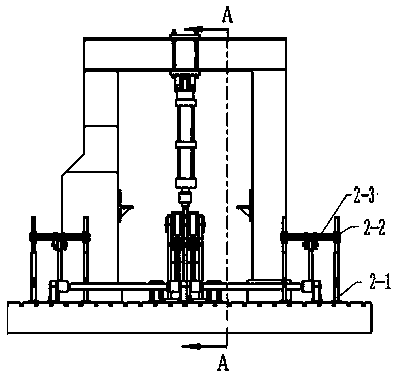

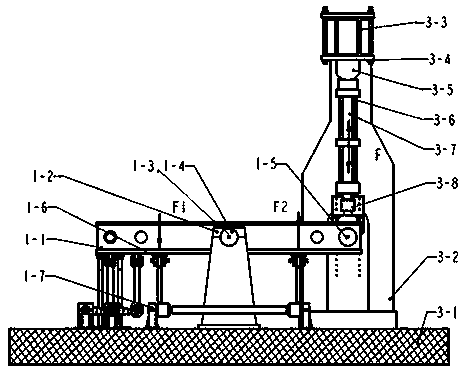

[0036] Please refer to Figure 1 to Figure 8 , a hydraulic single-point two-way loading test device for anti-rolling torsion bar, including a platform 3-1, a force device installed on the right part of the platform, a double beam lever mechanism installed on the platform, and a left part installed on the platform adjustable support device.

[0037] The double beam lever mechanism is mainly composed of a side rolling beam 1-1, a rotating support 1-2, a rotating shaft 1-3, a shaft sleeve 1-4, a rotating hinge shaft 1-5, a mounting seat 1-6, and a suspension device 1-7 , Oil injection pipe 1-8, M16 fastening bolt 1-9, self-lubricating bearing 1-10, limit block 1-11, M10 fastening bolt 1-12. Its function is to install the anti-roll torsion bar and form the roll angle at the same time. The suspension device is installed on the platform. The rotating support is a trapezoidal support, and its longitudinal section is trapezoidal.

[0038] The adjustable supporting device is mainly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com