Impulse Loading Apparatus for Non-Static Inclined Conveyor Chains

A loading device and non-static technology, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems that cannot accurately reflect the real load-carrying performance of the conveyor chain, and achieve high self-adaptive performance and fast adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

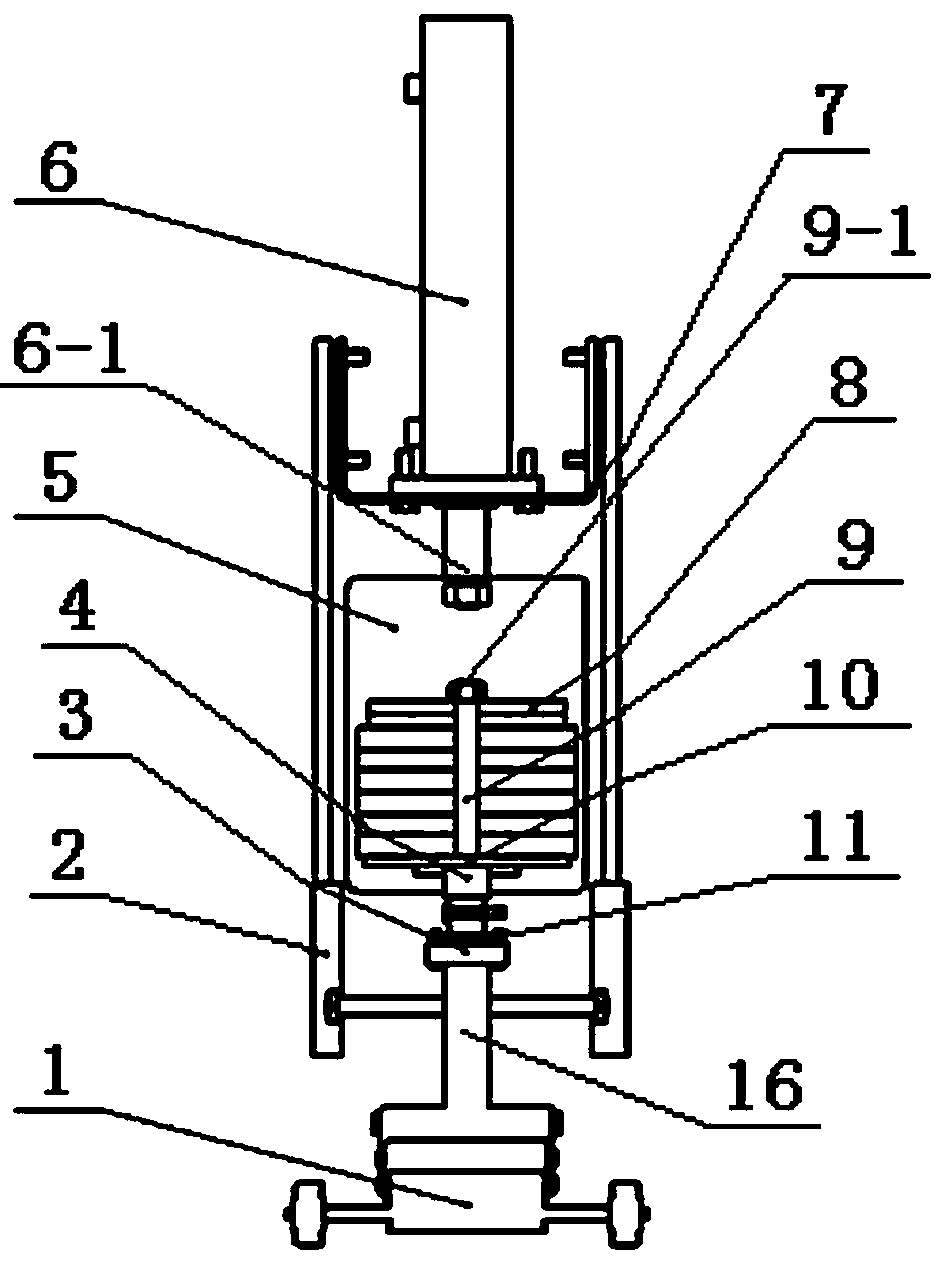

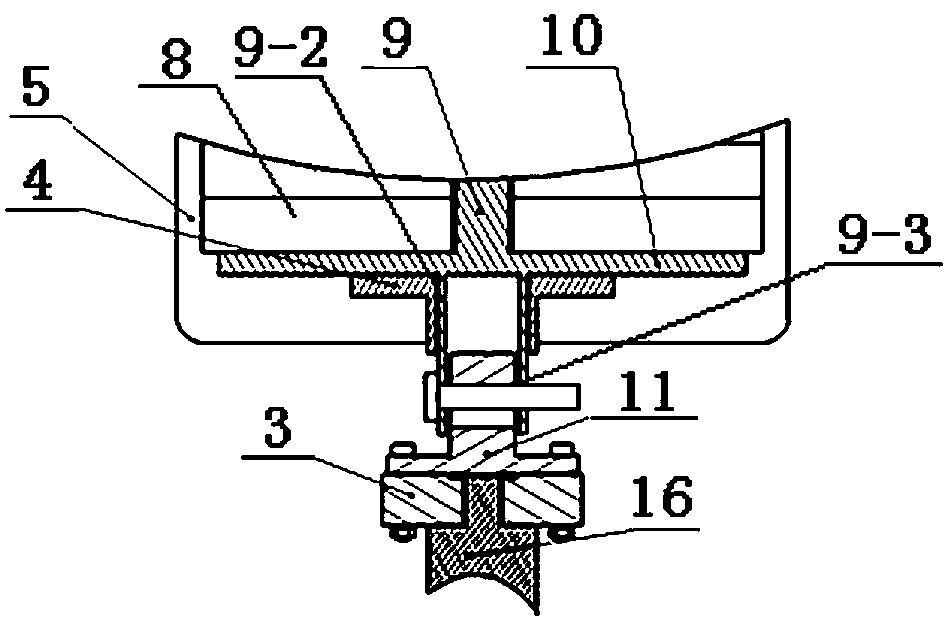

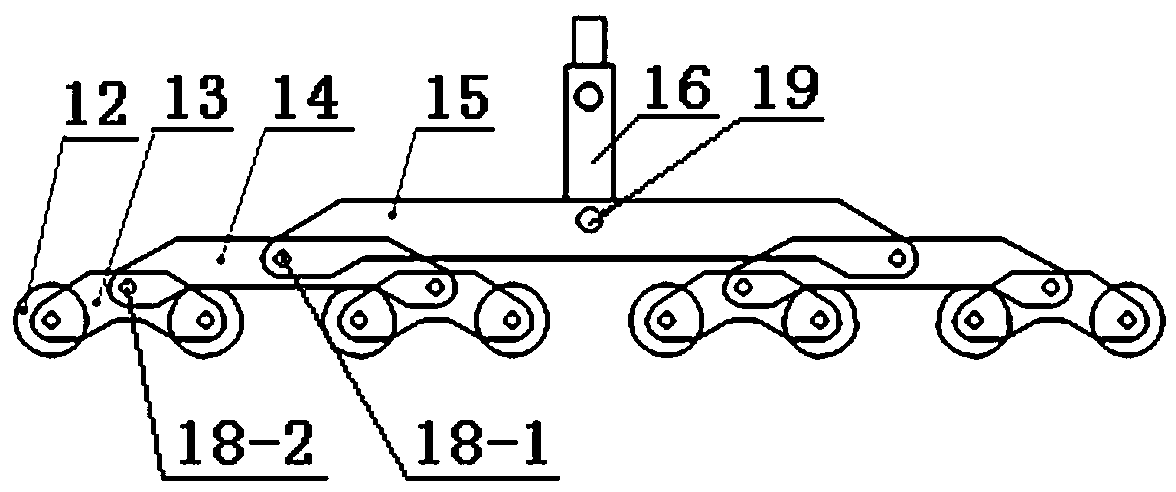

[0015] see Figure 1 ~ Figure 4 , this embodiment is suitable for the pulse load loading device of non-static inclined conveyor chain, including loading trolley 1, guide rail 2, MIK-LCLY force sensor 3, counterweight frame base 4, counterweight frame 5, telescopic hydraulic cylinder 6, frame 7. Counterweight 8, counterweight rod 9, counterweight base 10, flange shaft 11. Loading trolley 1 comprises loading wheel 12, wheel axle frame 13, wheel train bridge frame 14, wheel train girder 15, articulated rod 16, guide rod 17, guide bearing 18, articulated rod connecting shaft 19, guide rod 20.

[0016] see figure 1 , figure 2 , telescopic hydraulic cylinder 6 cylinder body is fixed on the bottom of frame 7 with bolts, and its telescopic rod 6-1 passes through the bottom center hole of frame 7 and the top center hole of counterweight frame 5 and uses nuts to connect the telescopic hydraulic cylinder The telescopic link of 6 is fixedly connected with counterweight frame 5. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com