Support assembly for the screw of a decanter screw centrifuge

A support and centrifuge technology, which is applied to centrifuges, centrifuges with rotating drums, bearings for rotating motion, etc., and can solve problems such as failure of a single axial support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

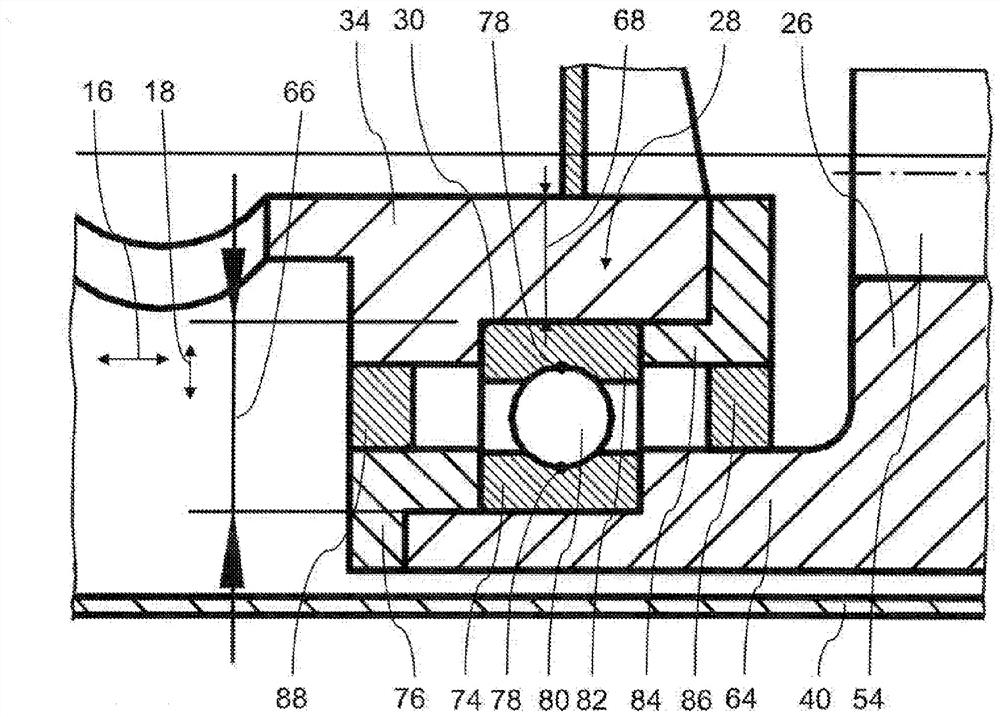

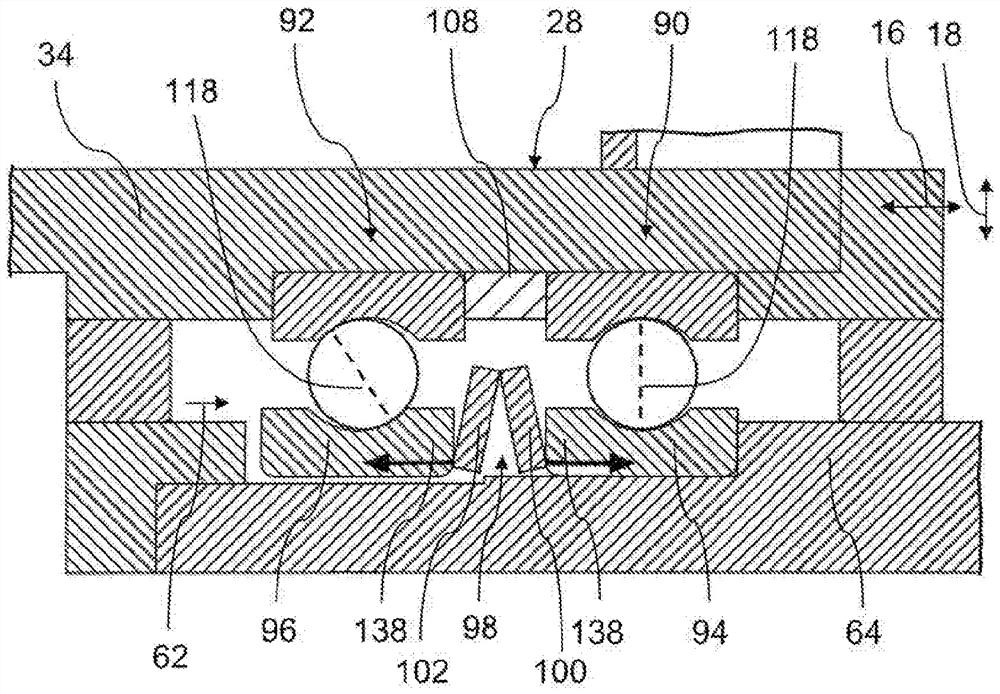

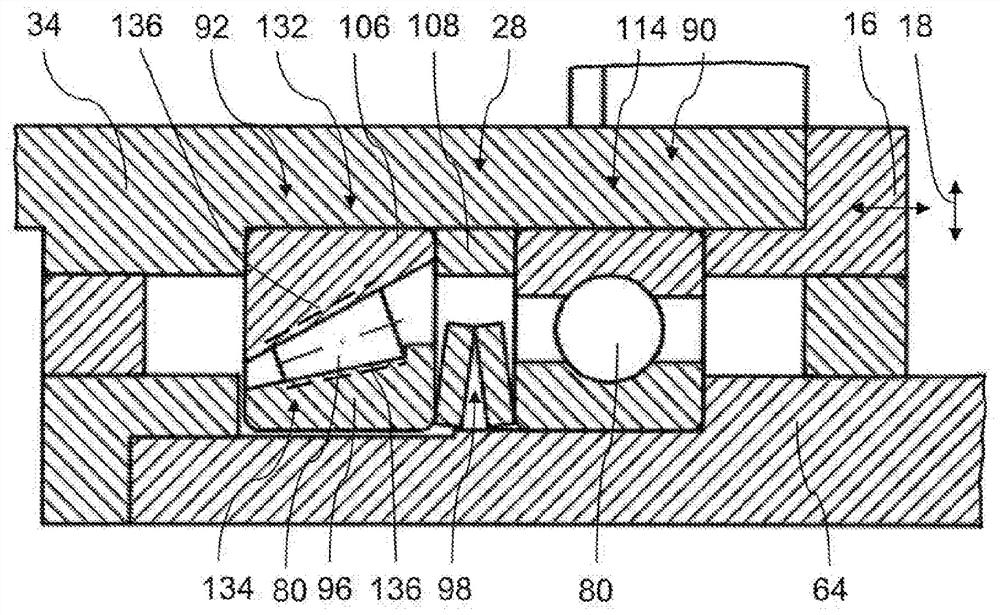

[0031] figure 1 A decanter screw centrifuge 10 is shown with its hollow cylindrical centrifuge barrel 14 rotatable about a centrifuge axis 12 . The centrifuge axis 12 defines an axial direction 16 and a radial direction 18 . The centrifuge cylinder 14 is surrounded by a housing 20 and is supported at its two axial end regions by means of a first cylinder support 22 and a second cylinder support 24 . The first bowl support 22 supports the centrifuge bowl 14 at a bowl cover 26 . The bowl cover 26 itself supports the screw 32 in the centrifuge bowl 14 by means of a bearing assembly 28 . The bearing arrangement 28 is designed as an axial bearing 30 .

[0032] The screw 32 comprises a substantially hollow-cylindrical screw hub 34 and a screw helix 36 which surrounds the screw hub radially on the outside. The screw hub 34 is rotatably supported on the centrifuge barrel at its one axial end region by means of the bearing arrangement 28 and at its other axial end region by means o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com