Plain bearing with hydrodynamic axial stop

A technology of radial bearings and axial stops, applied in the direction of sliding contact bearings, shafts and bearings, bearings for rotational motion, etc., can solve the problems of impossible assembly, lack of accessibility, etc., and achieve cost-effective and assembly-friendly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

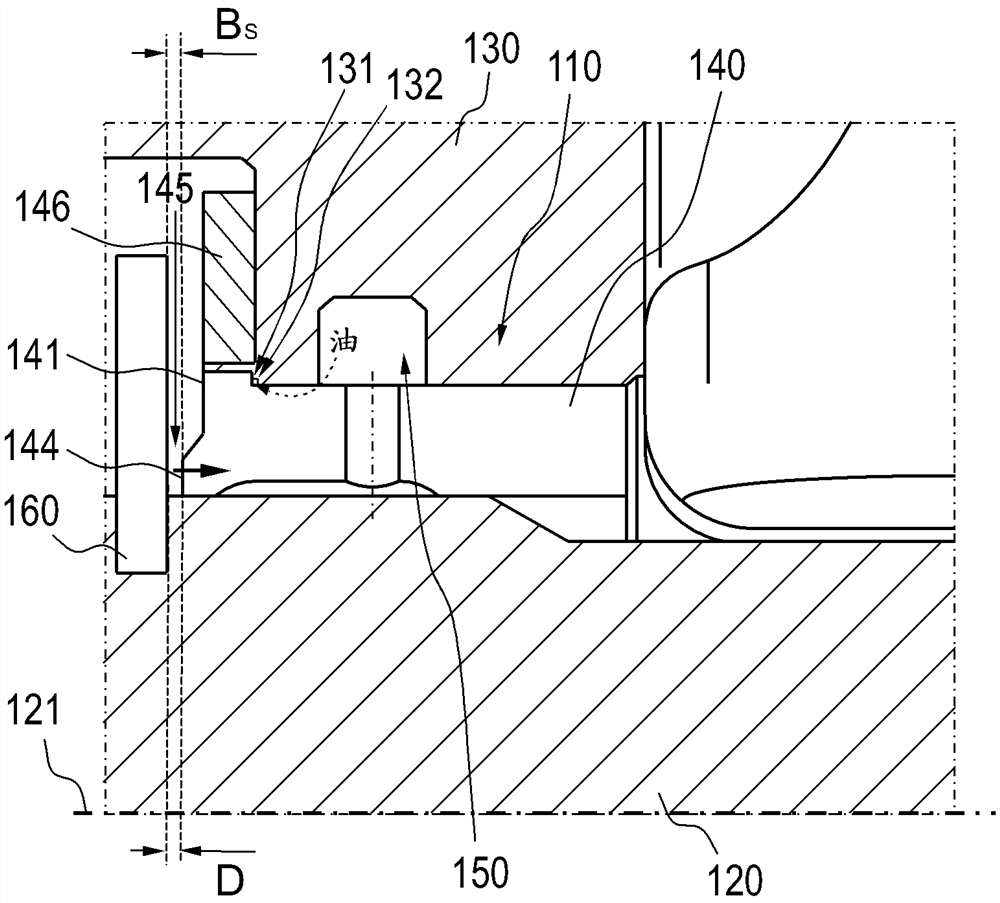

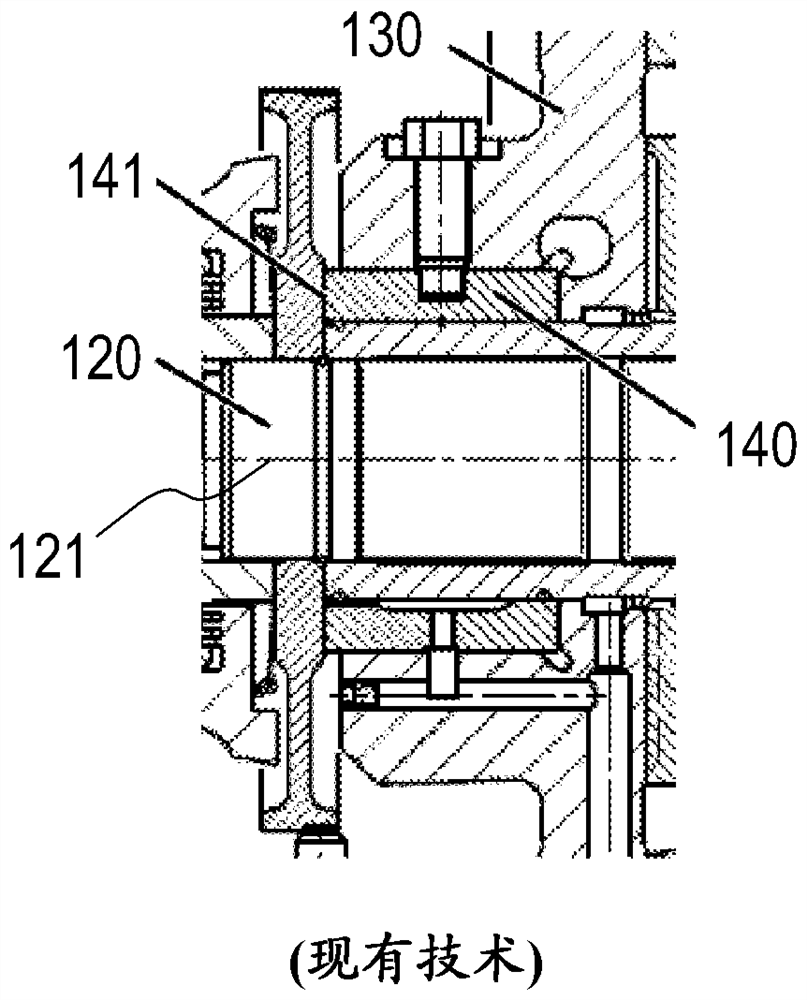

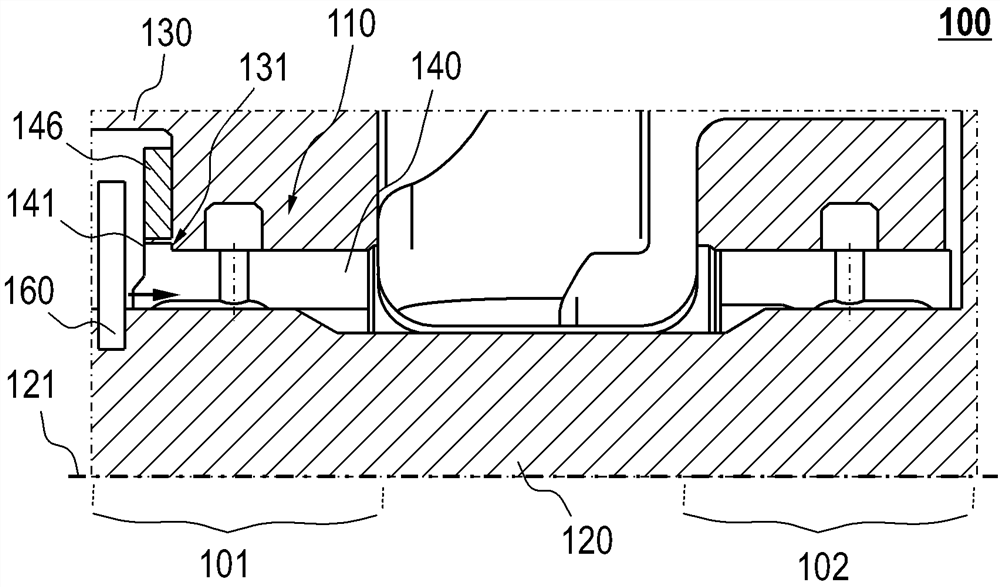

[0019] exist figure 1 A schematic cross-sectional view of a section of a turbocharger 100 with a radial bearing arrangement 110 according to the embodiment described here is shown in . especially figure 1 Radial bearing assembly 110 of turbocharger 100 is shown for supporting shaft 120 in bearing housing 130 . as in figure 1 As shown in , the radial bearing assembly 110 according to the present invention includes a radial bearing bushing 140 disposed between the shaft 120 and the bearing housing 130 . The radial bearing bushing 140 has a radially outwardly protruding collar 141 which cooperates axially with an axial stop 131 on the bearing housing 130 . Typically during assembly, the radial bearing bush (hereinafter also referred to as plain bearing bush GLB) is pushed axially into the bearing housing until the radially outwardly protruding flange 141 of the radial bearing bush 140 strikes against the Bearing housing 130. In particular, the radial bearing bush 140 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com