Ignition coil

A technology for ignition coils and connecting wires, which is applied in the direction of engine ignition, spark ignition controllers, spark plugs, etc., can solve the problems of non-realization of ignition feedback and high cost, and achieve the effects of low cost, guaranteed input, and friendly assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

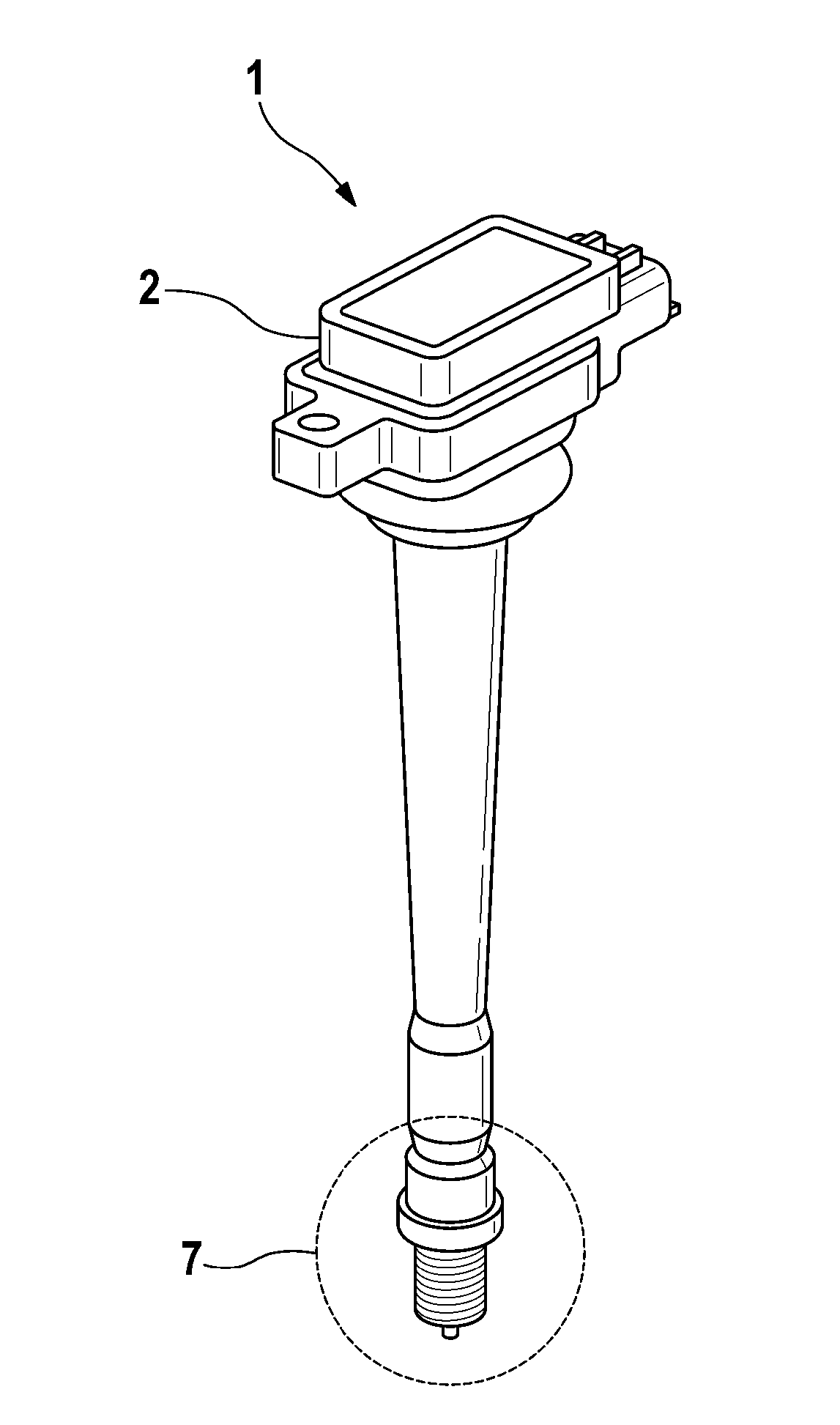

[0026] An ignition coil 1 according to a first embodiment of the present invention and a method of manufacturing the same will be described below with reference to FIGS. 1 and 2 .

[0027] FIG. 1 shows a perspective external view of an ignition coil 1 according to the invention. A housing 2 is arranged on top of the drawing, in which housing the winding components are arranged. The housing 2 is substantially made of plastic, the properties of which are suitable for the operating conditions when used in a motor vehicle. Arranged below the housing is a rod which terminates on the bottom side with a spark plug connection 7 .

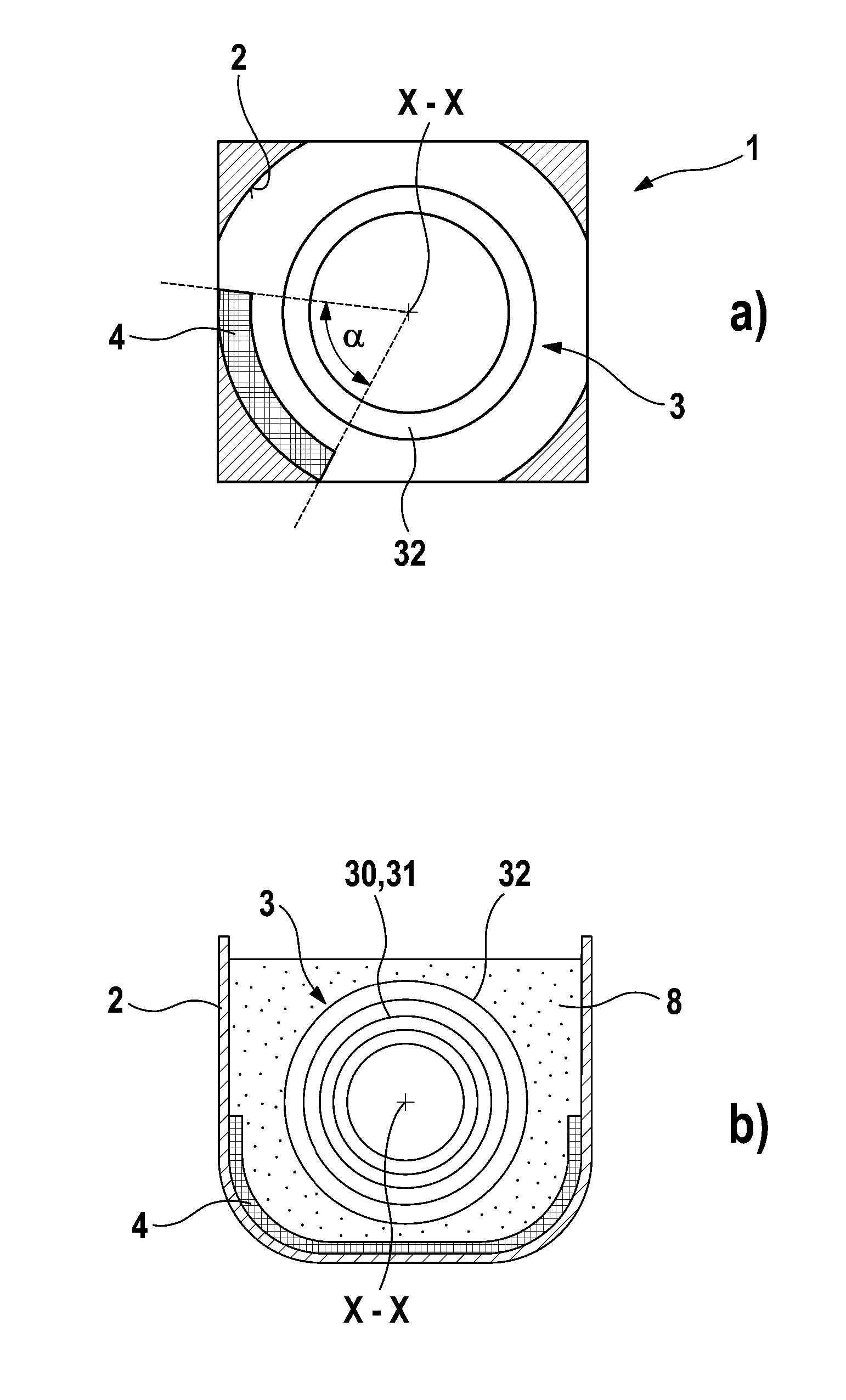

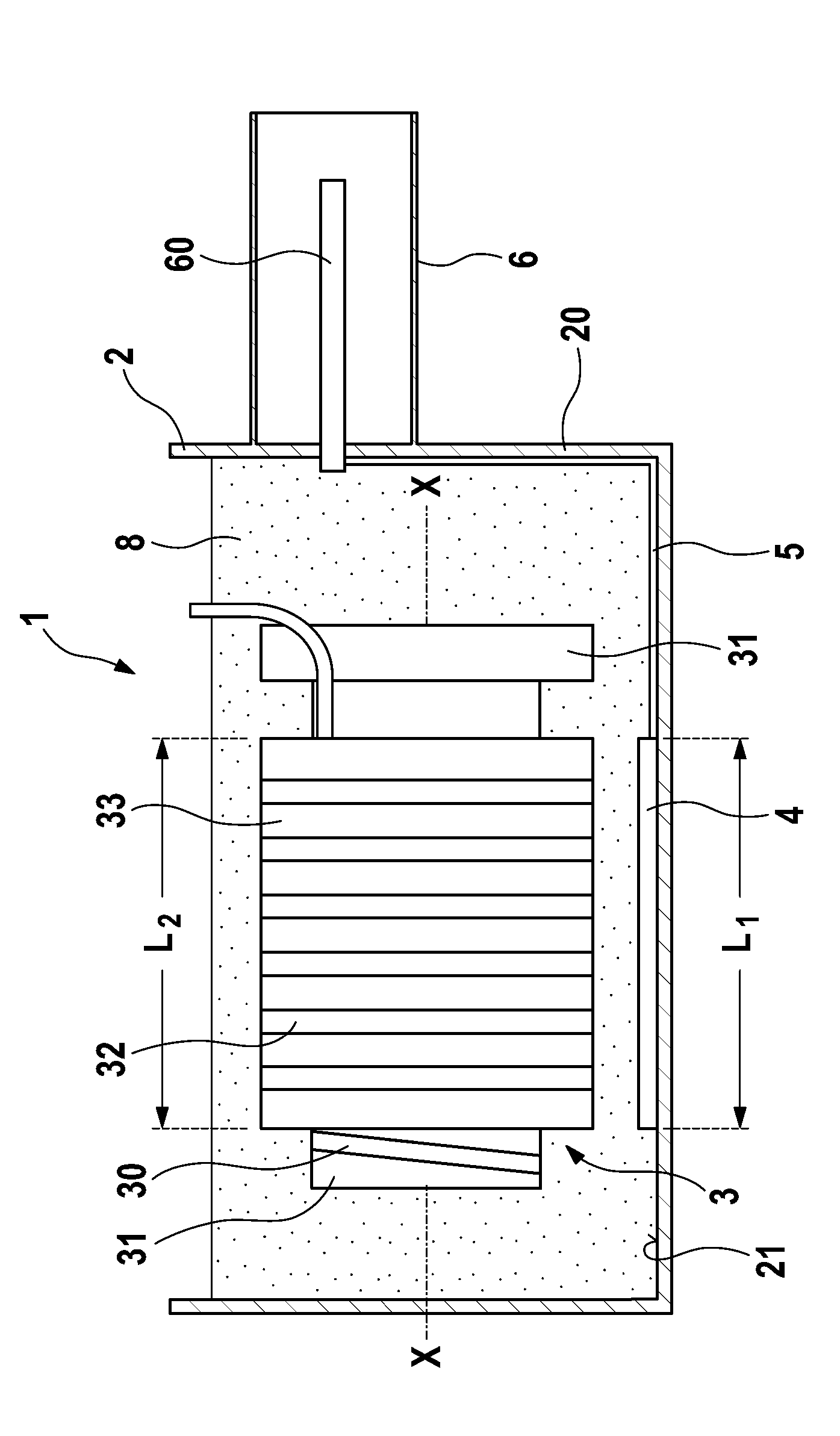

[0028] FIG. 2 shows an internal view of the housing 2 of the ignition coil 1 . Arranged inside the housing 2 is a winding part 3 , which on its outer side has a secondary winding 32 inserted into a secondary winding carrier 33 . In the secondary winding carrier 33 , the primary winding 30 is inserted coaxially into the primary winding carrier 31 . Prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com