Elastic element for a fastening point for a rail for rail vehicles, and fastening point

A technology for elastic elements and rail vehicles, which is applied in the field of elastic elements and fixed points for rail vehicle track fixing points, and can solve problems such as buffering effect limitation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

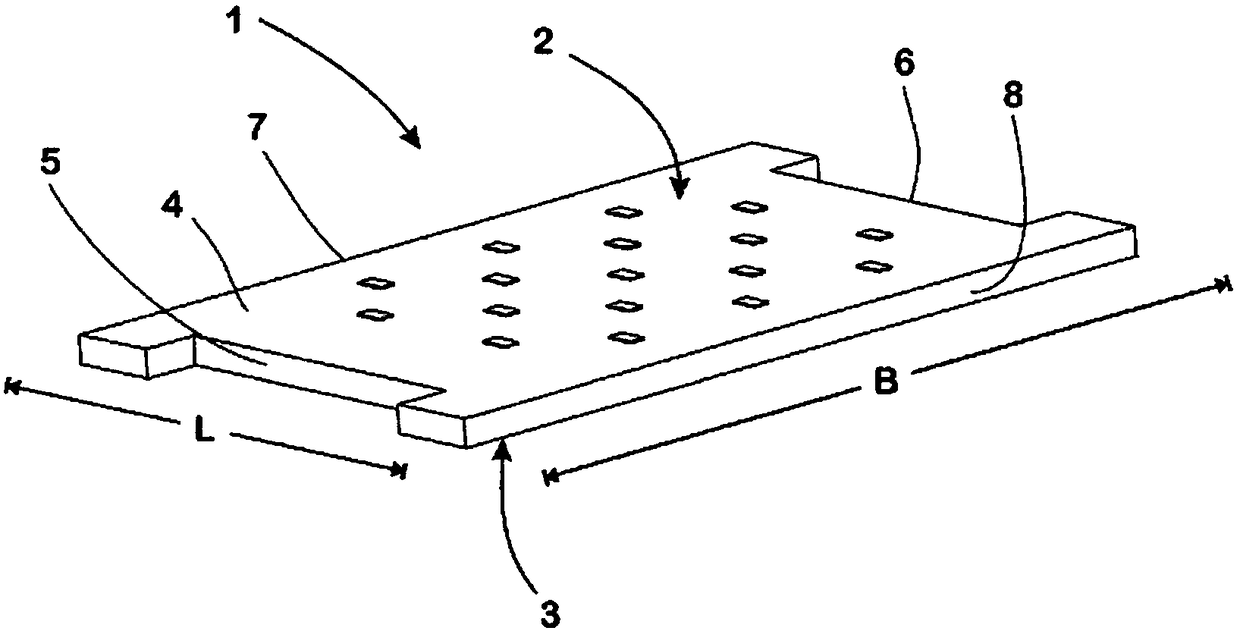

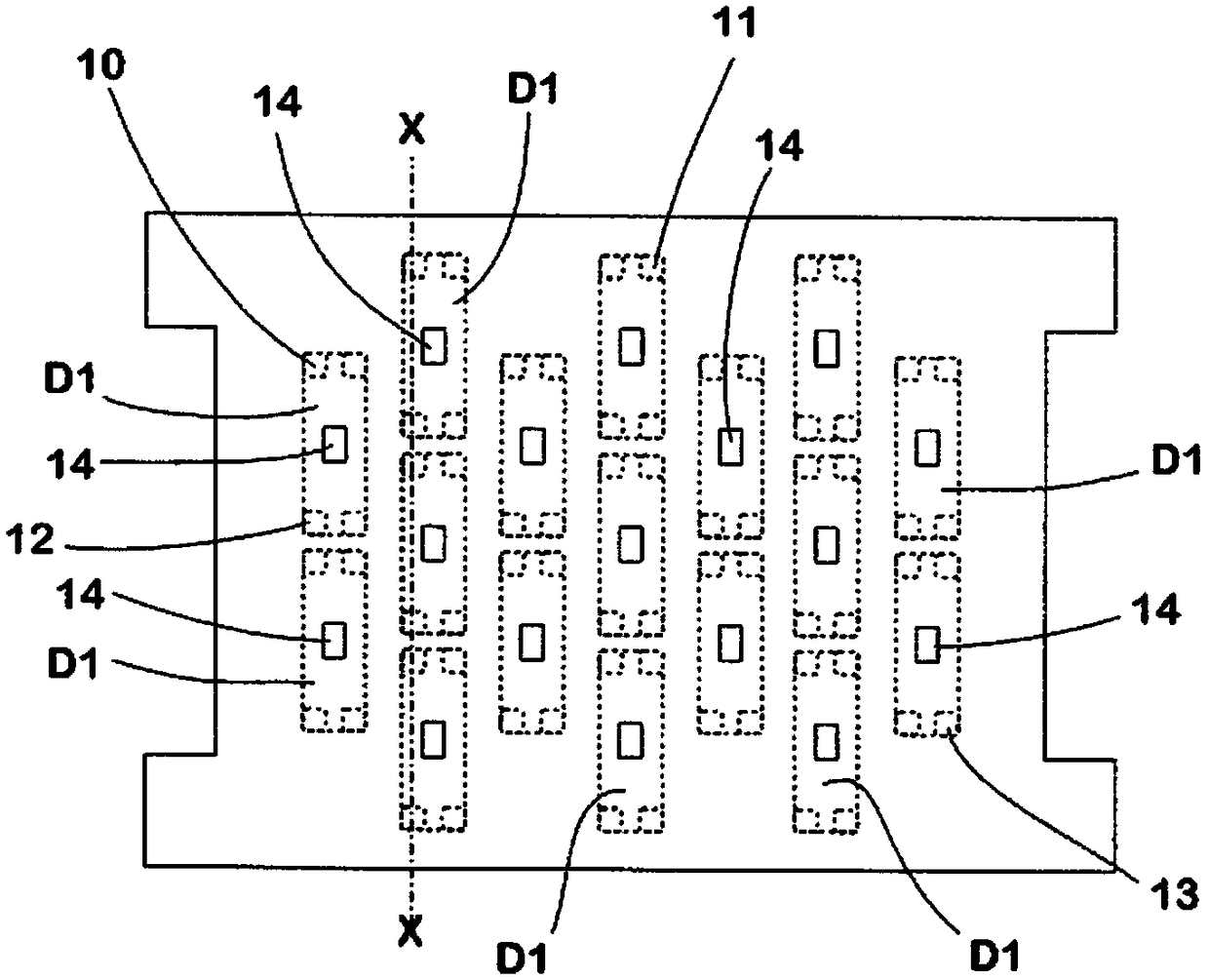

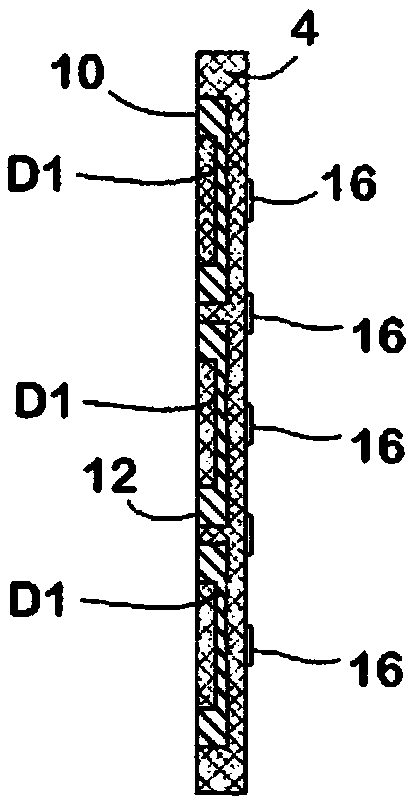

[0064] exist Figure 9 The fixing point B shown in , where the rail S is fixed to the concrete sleepers forming the base U, consists of a rail fixing system comprising two fastening clips SK1, SK2, two guide Plates FP1, FP2, two fastening bolts SR1, SR2 required for fastening the respective fastening clips SK1, SK2 as fastening means and a spring element formed substantially rectangular in top view, which is shown in all drawings are marked with a "1" regardless of their design shown in the figure.

[0065] One of the fastening clips SK1, SK2, one of the guide plates FP1, FP2 and one of the fastening bolts SR1, SR2 are respectively placed on one of the longitudinal sides L1, L2 of the rail S, while the elastic element 1 is located on the rail S Between the rail foot SF and the base U. Correspondingly, the rail S with its rail foot SF rests on the support surface 2 corresponding to the rail of the spring element 1 , which rests on the base U with its support surface 3 corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com