A fertilizer applicator for peanut planting

A peanut planting and fertilizing device technology, applied in fertilizing devices, fertilizer distributors, agriculture, etc., can solve problems such as backache and lowering fertilization efficiency, and achieve the effects of preventing waste, improving fertilizing efficiency, and preventing backache and backache.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

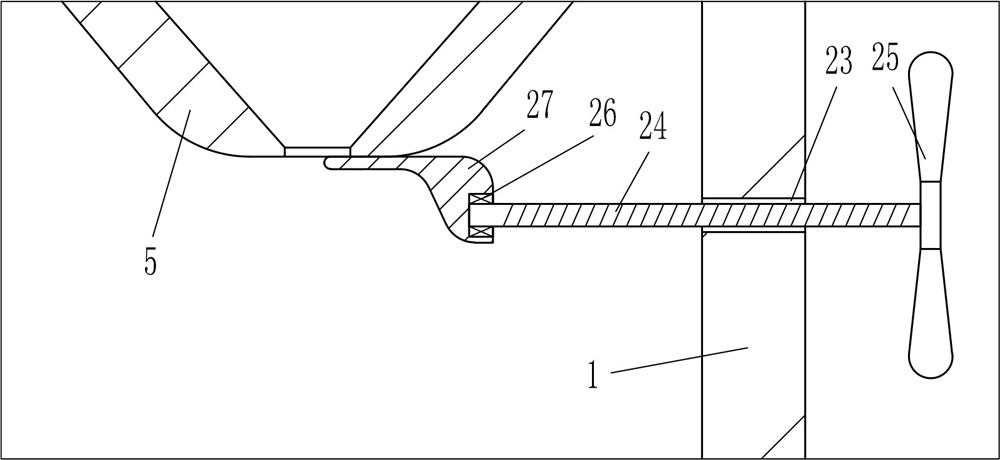

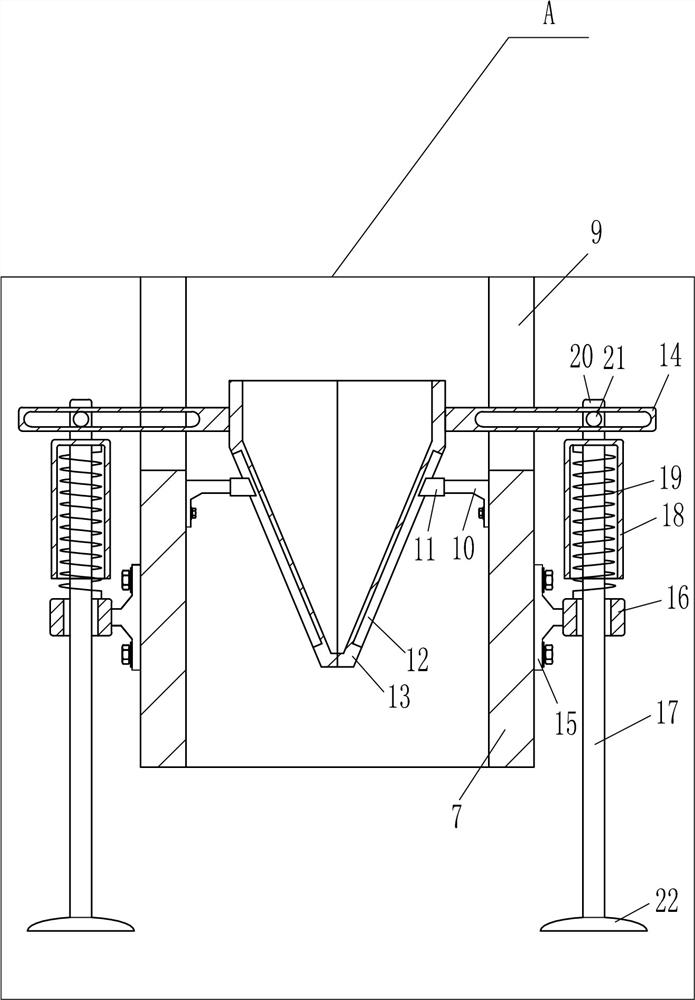

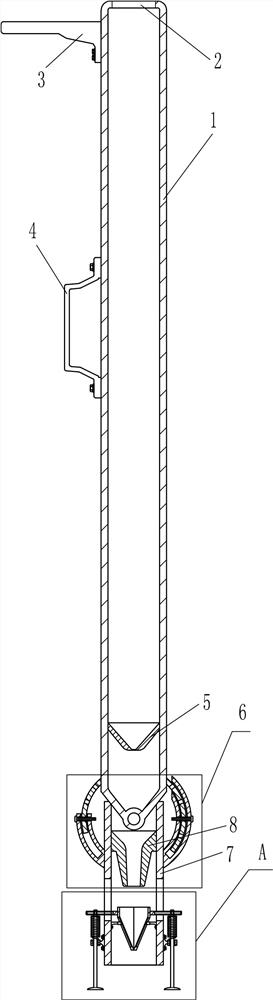

[0018] A fertilizer applicator for peanut planting, such as Figure 1-4 As shown, it includes a first hollow tube 1, a first handle 3, a second handle 4, a first conical funnel 5, an adjustment device 6, a second hollow tube 7, a second conical funnel 8, a first support 10, Slider 11, slide rail 12, half-tapered funnel 13, straight plate 14, second support 15, first sliding sleeve 16, first sliding rod 17, hollow sleeve 18, spring 19, fixed plate 20, pin Rod 21 and support plate 22, the top of the first hollow tube 1 has a first through hole 2 for conveying, the first handle 3 is fixed on the upper part of the left wall of the first hollow tube 1, and the second handle 4 is installed on the first hollow tube 1 The upper part of the left wall, the second handle 4 is located on the lower side of the first handle 3, the first conical funnel 5 is arranged at the lower part of the inner wall of the first hollow tube 1, and the lower part of the outer wall of the first hollow tube 1...

Embodiment 2

[0020] A fertilizer applicator for peanut planting, such as Figure 1-4As shown, it includes a first hollow tube 1, a first handle 3, a second handle 4, a first conical funnel 5, an adjustment device 6, a second hollow tube 7, a second conical funnel 8, a first support 10, Slider 11, slide rail 12, half-tapered funnel 13, straight plate 14, second support 15, first sliding sleeve 16, first sliding rod 17, hollow sleeve 18, spring 19, fixed plate 20, pin Rod 21 and support plate 22, the top of the first hollow tube 1 has a first through hole 2 for conveying, the first handle 3 is fixed on the upper part of the left wall of the first hollow tube 1, and the second handle 4 is installed on the first hollow tube 1 The upper part of the left wall, the second handle 4 is located on the lower side of the first handle 3, the first conical funnel 5 is arranged at the lower part of the inner wall of the first hollow tube 1, and the lower part of the outer wall of the first hollow tube 1 ...

Embodiment 3

[0023] A fertilizer applicator for peanut planting, such as Figure 1-4 As shown, it includes a first hollow tube 1, a first handle 3, a second handle 4, a first conical funnel 5, an adjustment device 6, a second hollow tube 7, a second conical funnel 8, a first support 10, Slider 11, slide rail 12, half-tapered funnel 13, straight plate 14, second support 15, first sliding sleeve 16, first sliding rod 17, hollow sleeve 18, spring 19, fixed plate 20, pin Rod 21 and support plate 22, the top of the first hollow tube 1 has a first through hole 2 for conveying, the first handle 3 is fixed on the upper part of the left wall of the first hollow tube 1, and the second handle 4 is installed on the first hollow tube 1 The upper part of the left wall, the second handle 4 is located on the lower side of the first handle 3, the first conical funnel 5 is arranged at the lower part of the inner wall of the first hollow tube 1, and the lower part of the outer wall of the first hollow tube 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com