Fertilizer concentrating and forming machine

A molding machine and fertilizer technology, applied in fertilizer forms, fertilizer mixtures, fertilizer application devices, etc., can solve problems such as being unsuitable for processing soft, bulky, non-sticky and fibrous materials, achieving high production efficiency and avoiding local blockages Phenomenon and die loss, the effect of convenient fertilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

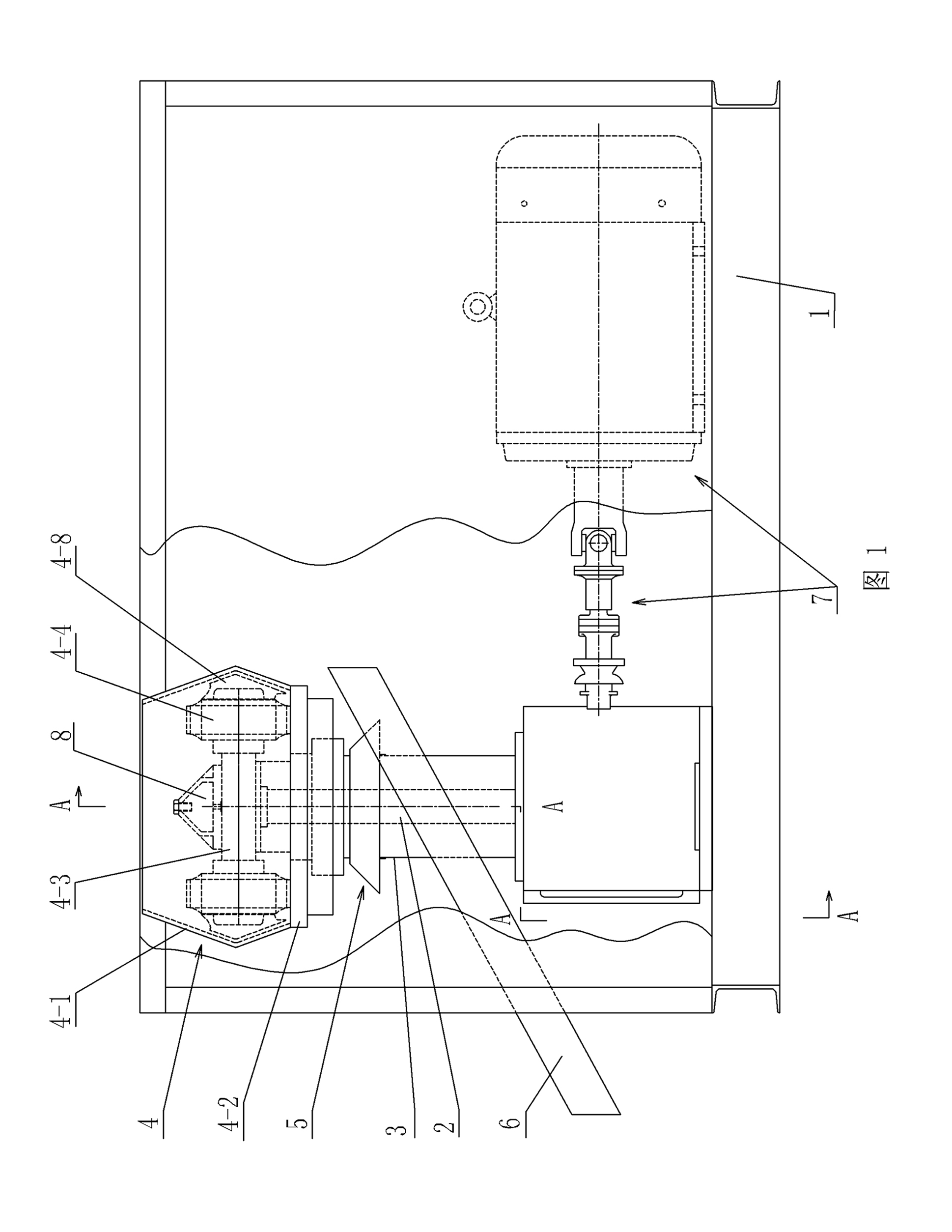

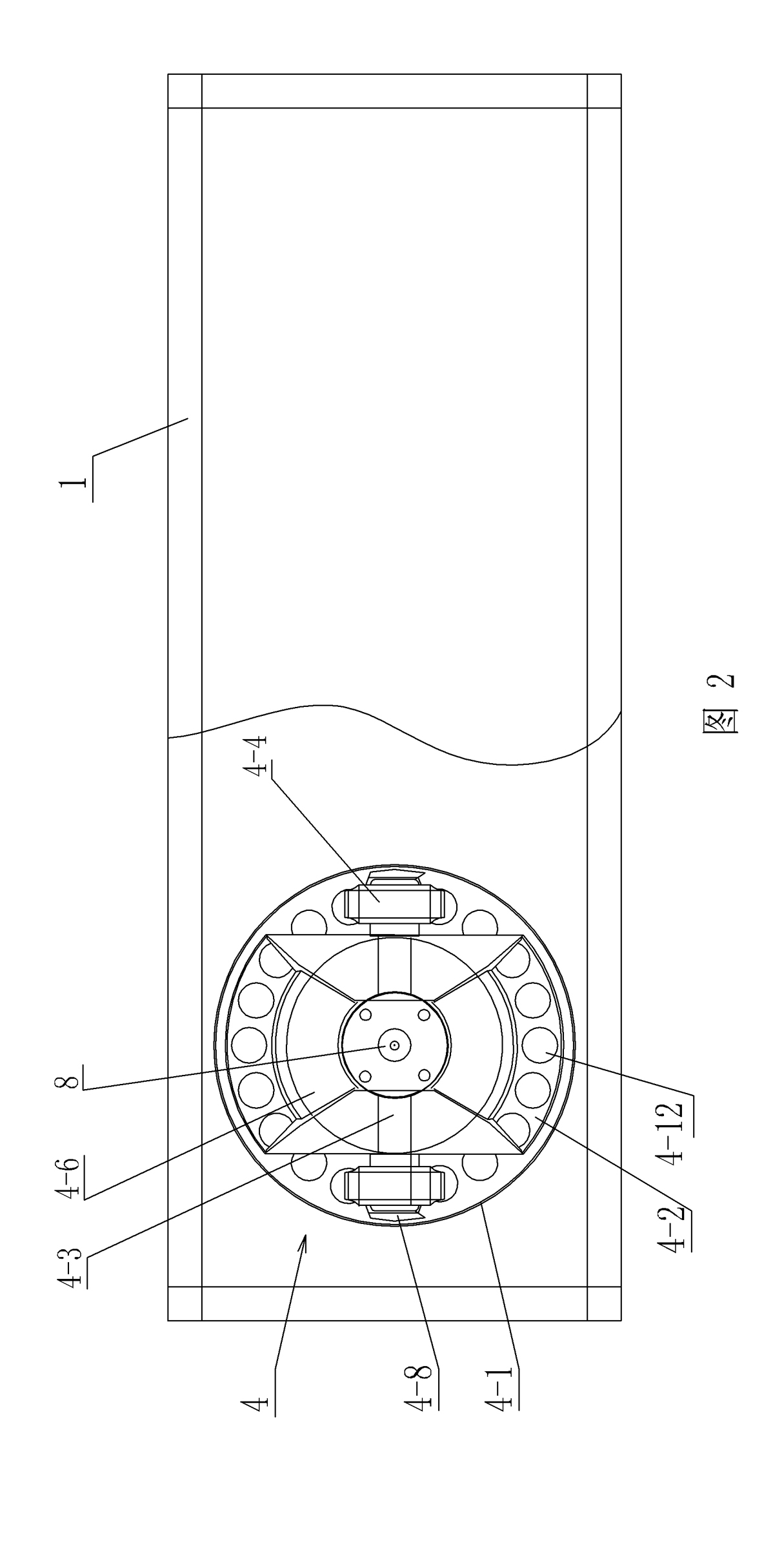

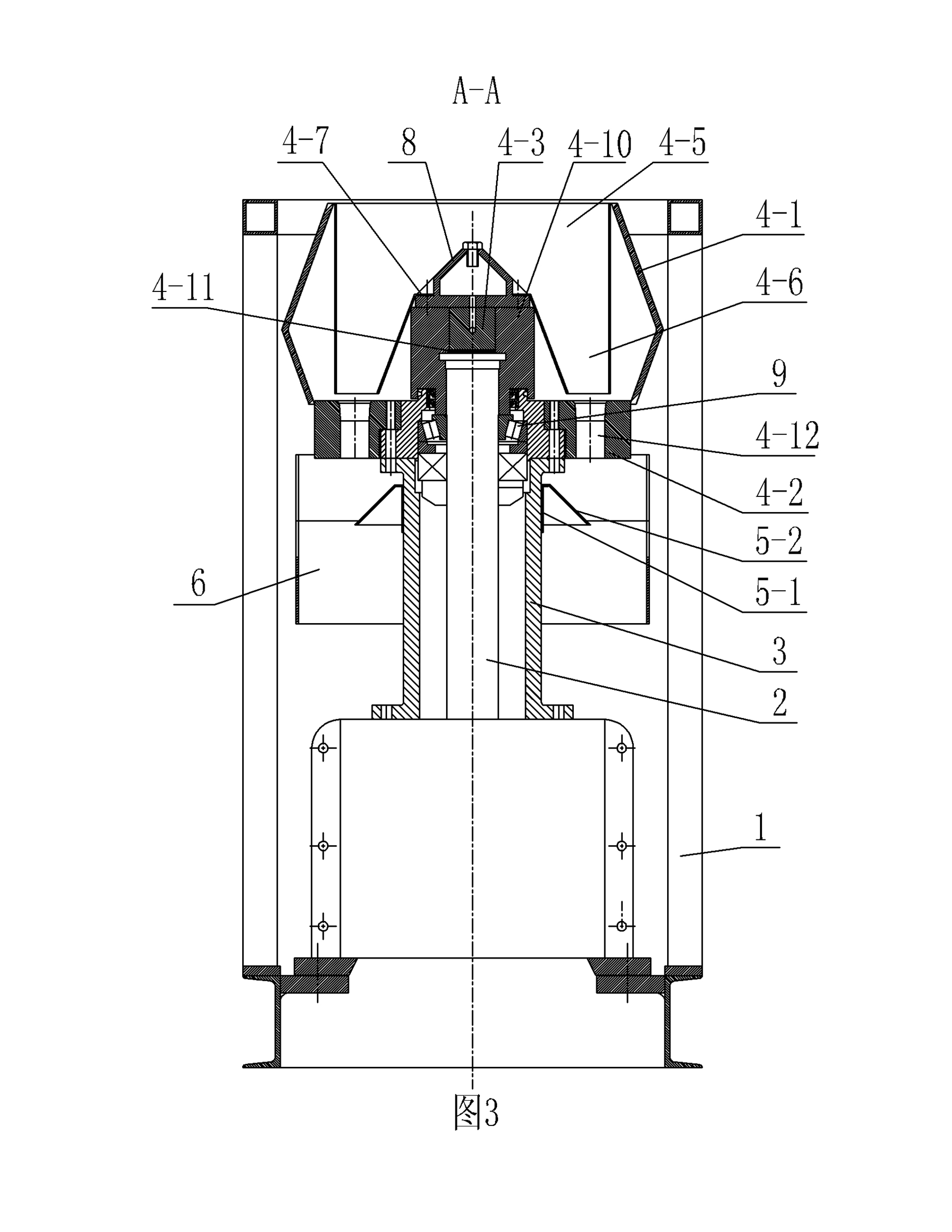

[0032] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments:

[0033] Such as Figure 1-Figure 8 Shown is a fertilizer concentration molding machine provided by the present invention, which is characterized in that it includes a frame 1, a main shaft 2 vertically installed on the frame 1, a sleeve placed on the periphery of the main shaft 2 and relatively fixedly connected with the frame 1. The main shaft outer sleeve 3, the fertilizer extruding device 4 arranged on the main shaft 2 and the upper part of the main shaft outer sleeve 3, the cutting device 5 located below the outlet of the fertilizer extruding device 4, and the discharge guide device located below the cutting device 5 6 and a power transmission device 7 connected to the lower end of the main shaft 2 to drive the main shaft 2 to rotate. The power transmission device 7 may be composed of an electric motor and a variable speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com