A spraying high-speed turbine cleaning device

A technology for cleaning devices and turbines, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems that spraying high-speed turbines is difficult to obtain obvious cleaning effects, and achieve limited support for components and supporting facilities. The effect of easy production and strong cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

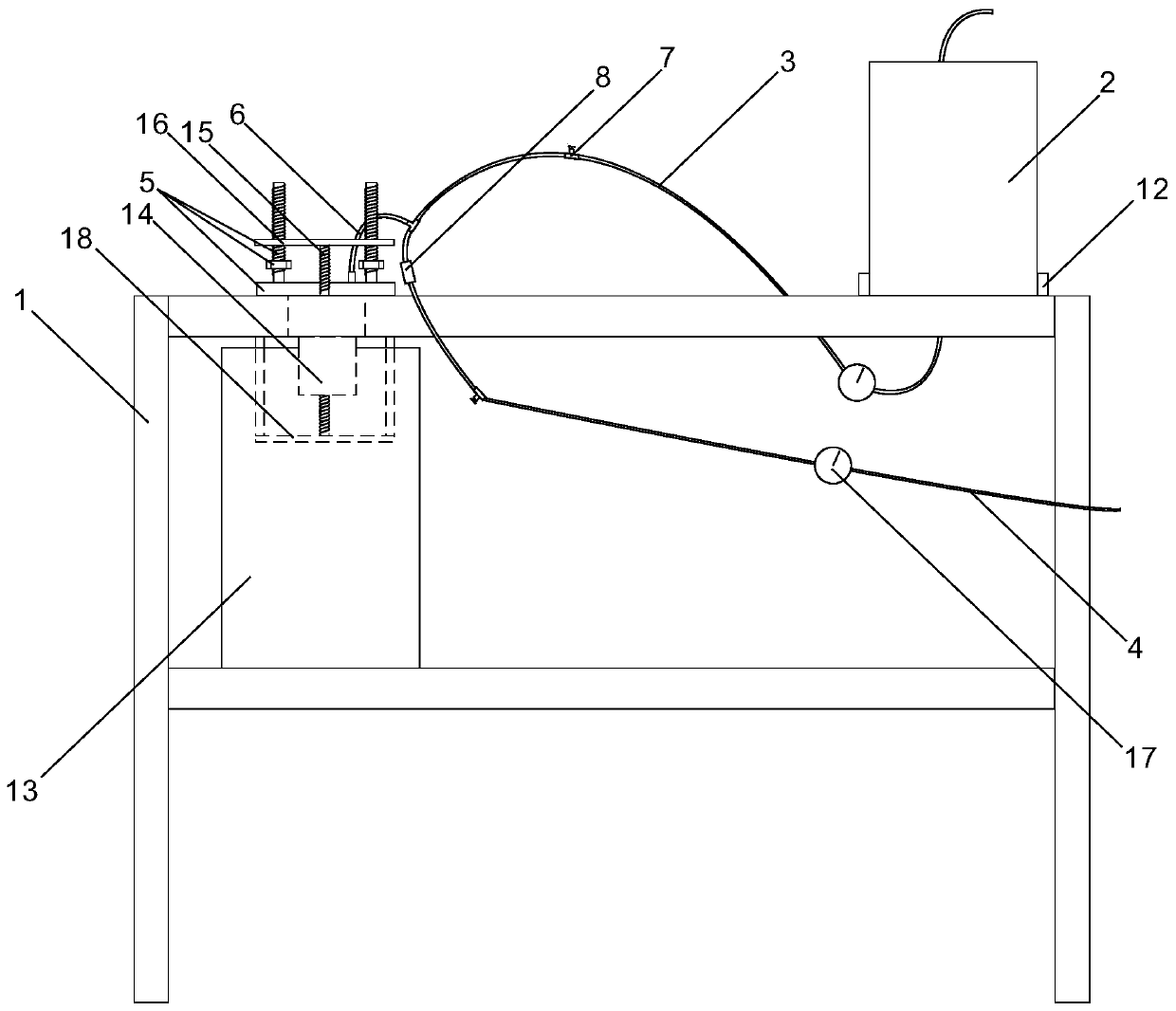

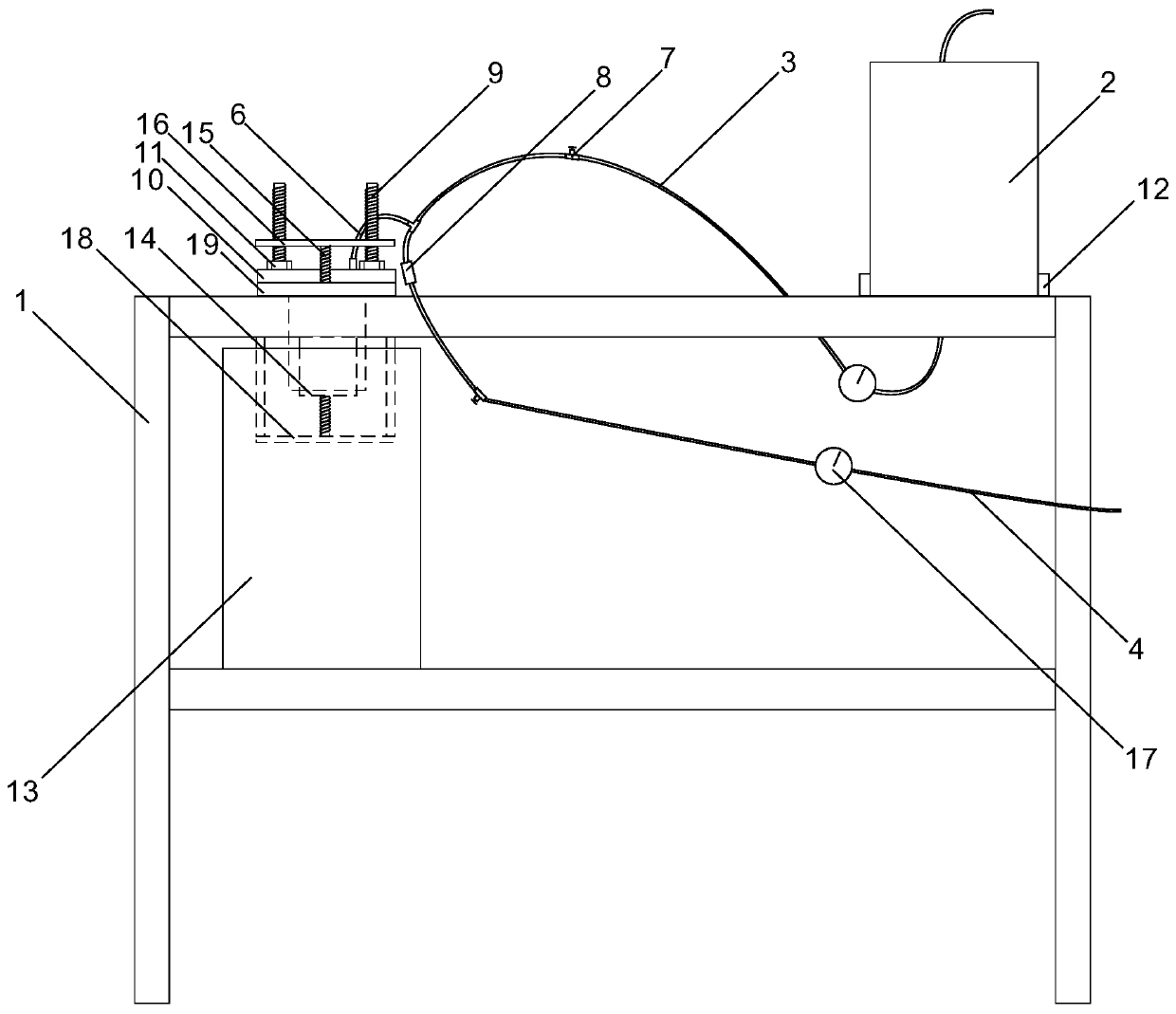

[0022] Such as figure 1 , figure 2 As shown, a spraying high-speed turbine cleaning device includes a main body bracket 1, a pressurized solvent tank 2, a pressurized solvent pipeline 3 and an air blowing pipeline 4. The main body bracket 1 has two layers, and the upper layer is provided with a fixed spraying high-speed turbine to be cleaned. The workpiece fixture 5 is provided with four nozzles corresponding to the positions of the air holes on the end face of the spraying high-speed turbine on the workpiece fixture 5. The pressurized solvent tank 2 is also placed on the upper layer of the main body support 1, and the pressurized solvent pipeline 3 is connected to the pressurized solvent pipeline. 3, the pressurized solvent pipeline 3 and the blowing pipeline 4 are connected to the workpiece holder 5 and communicate with the nozzle. The main body bracket 1 is provided with a workpiece socket adapted to the diameter of the small end of the spraying high-speed turbine. The wo...

Embodiment 2

[0025] There are three studs 9, the workpiece pressing plate 10 is rectangular, and the bottom of the workpiece pressing plate 10 is provided with two spouts. All the other are with embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap