Settlement and convergence preventing hydraulic side supporting device for lower bench excavation of soft rock tunnel

A bench excavation and anti-settlement technology, applied in the direction of mine roof support, mining equipment, earthwork drilling, etc., can solve the problems of slow construction speed, increased construction volume, tunnel collapse, etc., to prevent insufficient support size and increase construction volume. , the effect of slowing down the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

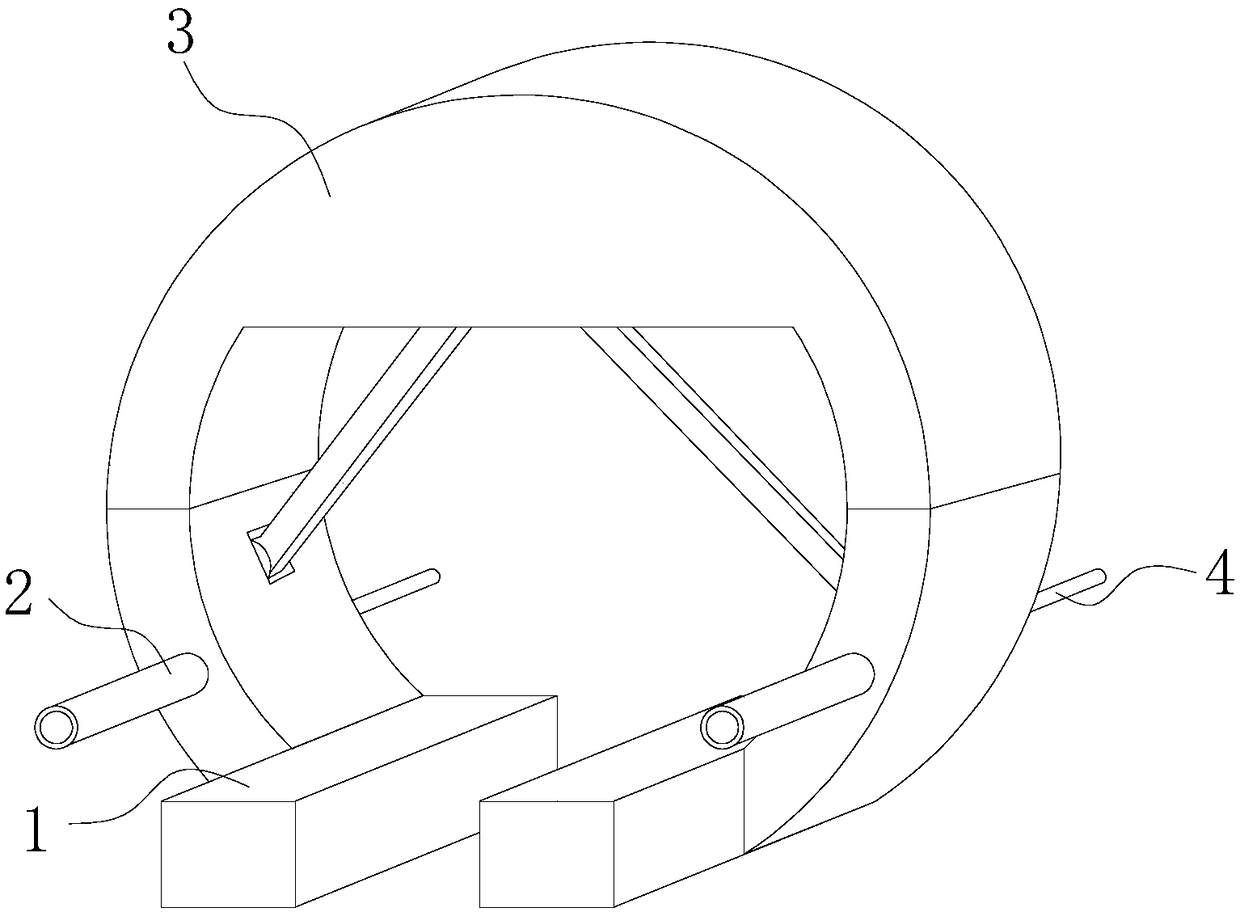

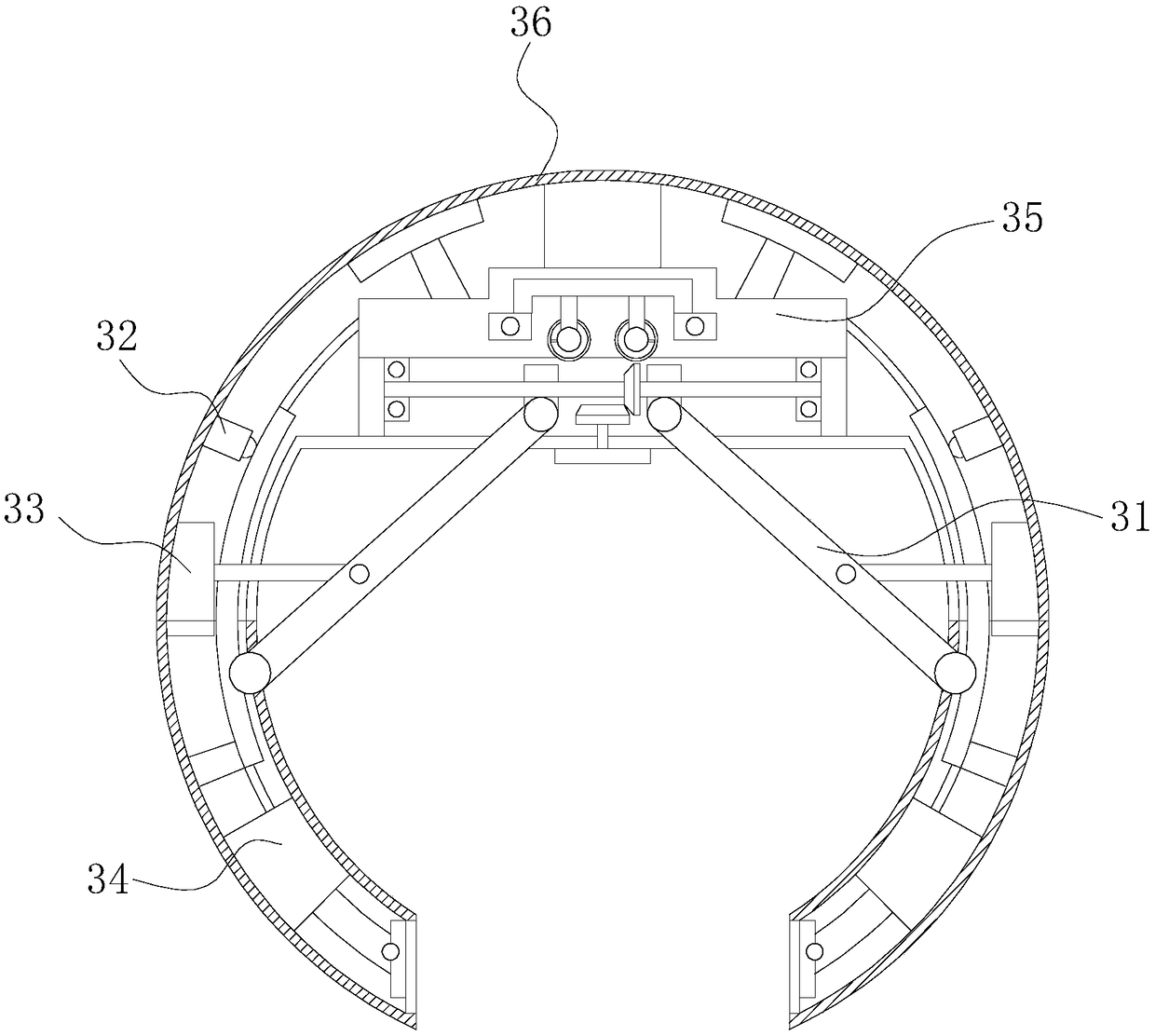

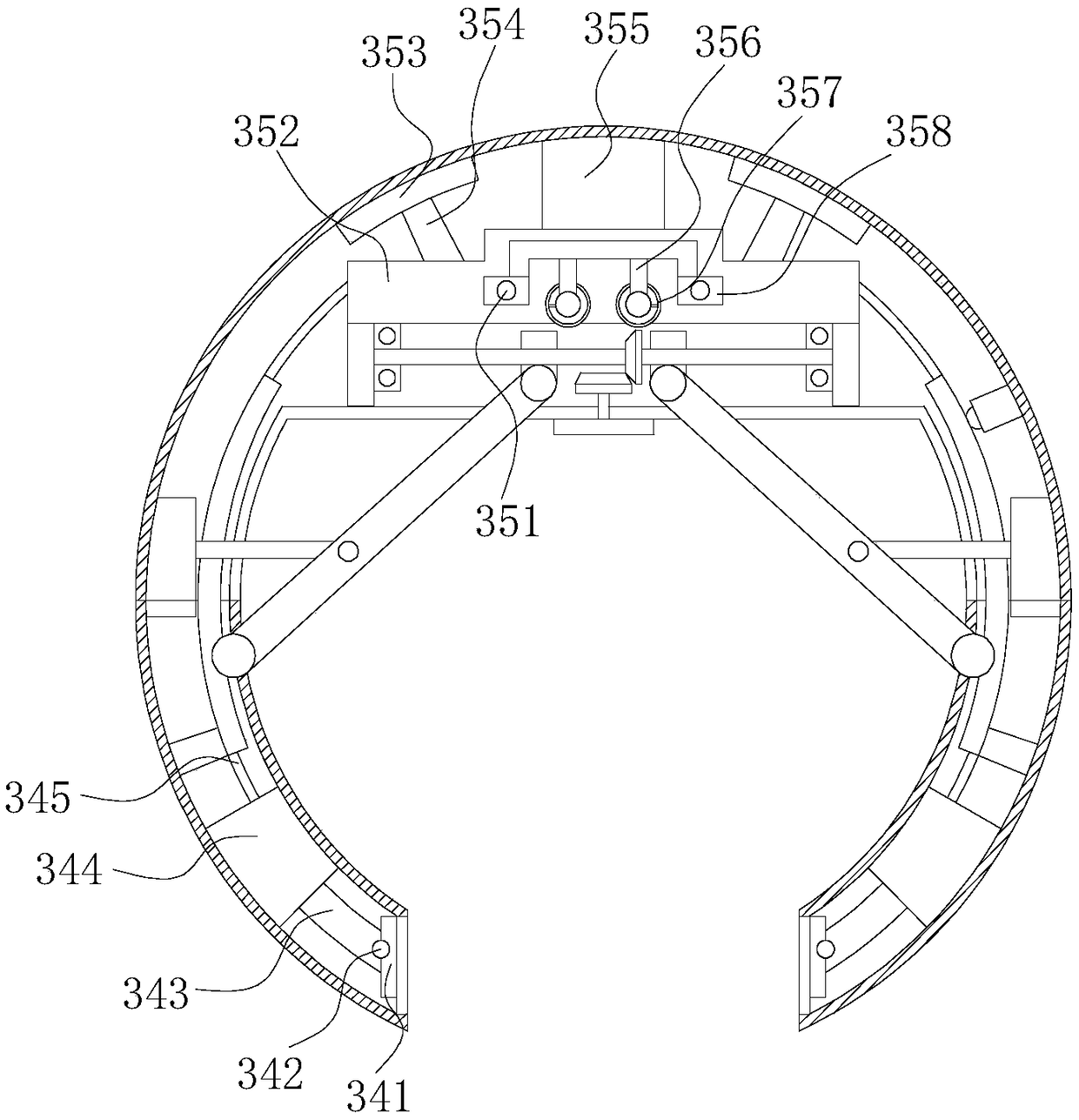

[0031] see Figure 1-Figure 10, the present invention provides a subsidence and convergence hydraulic side support device for the excavation of the lower steps of a soft rock tunnel. One is horizontally installed on both sides of the lower end of the adjusting balance device 3, the linkage through pipe 2 is vertically installed on the front surface of the adjusting balance device 3, and the splicing rod 4 is vertically installed on the rear surface of the adjusting balance device 3, The linkage through pipe 2 is installed in front of the splicing rod 4 through the adjustment balance device 3, the linkage through pipe 2 is installed above the bearing plate 1, and the adjustment balance force device 3 includes an adjustment mechanism 31, a linkage Mechanism 32, filling mechanism 33, unloading mechanism 34, anti-pressure mechanism 35, shell 36.

[0032] The adjustment mechanism 31 is installed horizontally inside the casing 36, the linkage mechanism 32 is mechanically transmitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com