Beneficiation equipment capable of finely screening ore quality

A technology of mineral processing equipment and ore, applied in the field of mineral processing equipment that can finely screen the quality of ore, can solve problems such as unfavorable mining site management, environmental impact, etc., to improve the degree of fineness and work efficiency, optimize work methods, and improve fineness and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

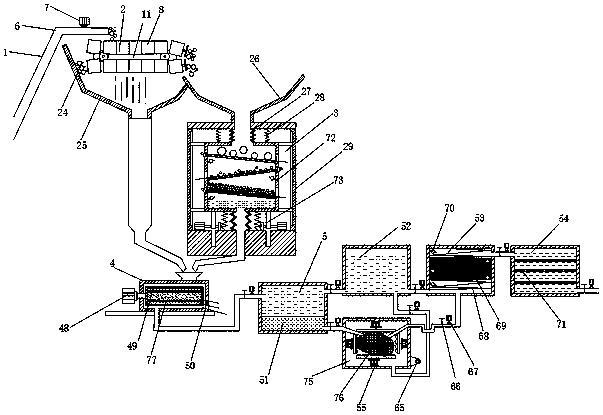

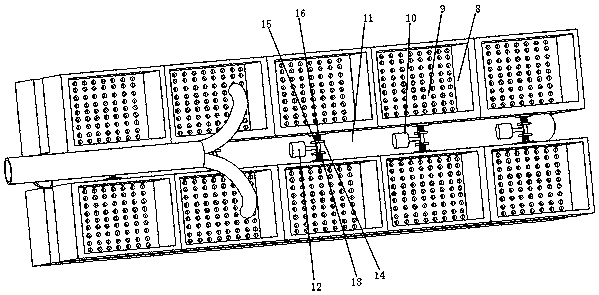

[0026] A mineral processing equipment capable of finely screening ore quality, comprising an ore feeding device 1, a water filtering device 2, a vibrating screen 3, a centrifugal sieve 4 and a water treatment device 5; the water filtering device 2 is arranged below the outlet of the ore feeding device 1 The water filtering device 2 includes crawler belts 11, two groups of water filtering frames 8, vibrating devices 10 and a slideway-23; the slideway-23 is fixed on both sides of the crawler belts 11, and the two groups of water filtering frames 8 are respectively arranged On the slideway one 23 on both sides; the vibration device 10 is arranged between two groups of water filter frames 8, and connects two groups of water filter frames 8; the water filter frame 8, vibration device 10 and slideway one 23 It rotates with the crawler belt 11; a water receiving bucket 25 and an ore receiving bucket 26 are arranged below the water filtering device 2, and the water receiving bucket 25 ...

Embodiment 2

[0033] Embodiment 2 is basically the same in structure and principle as Embodiment 1, except that a high-pressure water gun 24 is arranged on the inner wall of the water receiving bucket 25 . When the water filter frame 8 moves to the leftmost side with the crawler belt 11, the high-pressure water gun 24 sprays water into the water filter frame to clean the water filter frame.

Embodiment 3

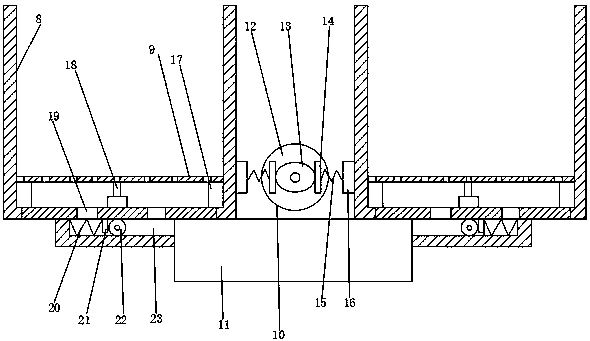

[0035] The structure and principle of this embodiment 3 are basically the same as that of embodiment 1, except that the bottom of the filter frame 8 is provided with a support column 17 and a hydraulic cylinder 18; the end of the push rod of the hydraulic cylinder 18 is provided with a filter plate 9 ; When the push rod of the hydraulic cylinder 18 is in the shortest state, the support column 17 withstands the water filter plate 9, assisting the hydraulic cylinder 18 to bear the weight; Through hole 19. When the water filter frame 8 moves to the far right with the crawler belt 11, the water filter frame 8 turns downwards, and the hydraulic cylinder 18 pushes out the water filter plate 9 together with the ore on the water filter plate 9; Water can flow out from the water filter through hole 19 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com