Wiring device and method

A wiring device and wiring pipe technology, applied in the direction of electrical components, etc., can solve the problems of long wiring cycle, high noise, poor construction site environment, etc., and achieve the effects of reducing labor costs, low noise, and shortening wiring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

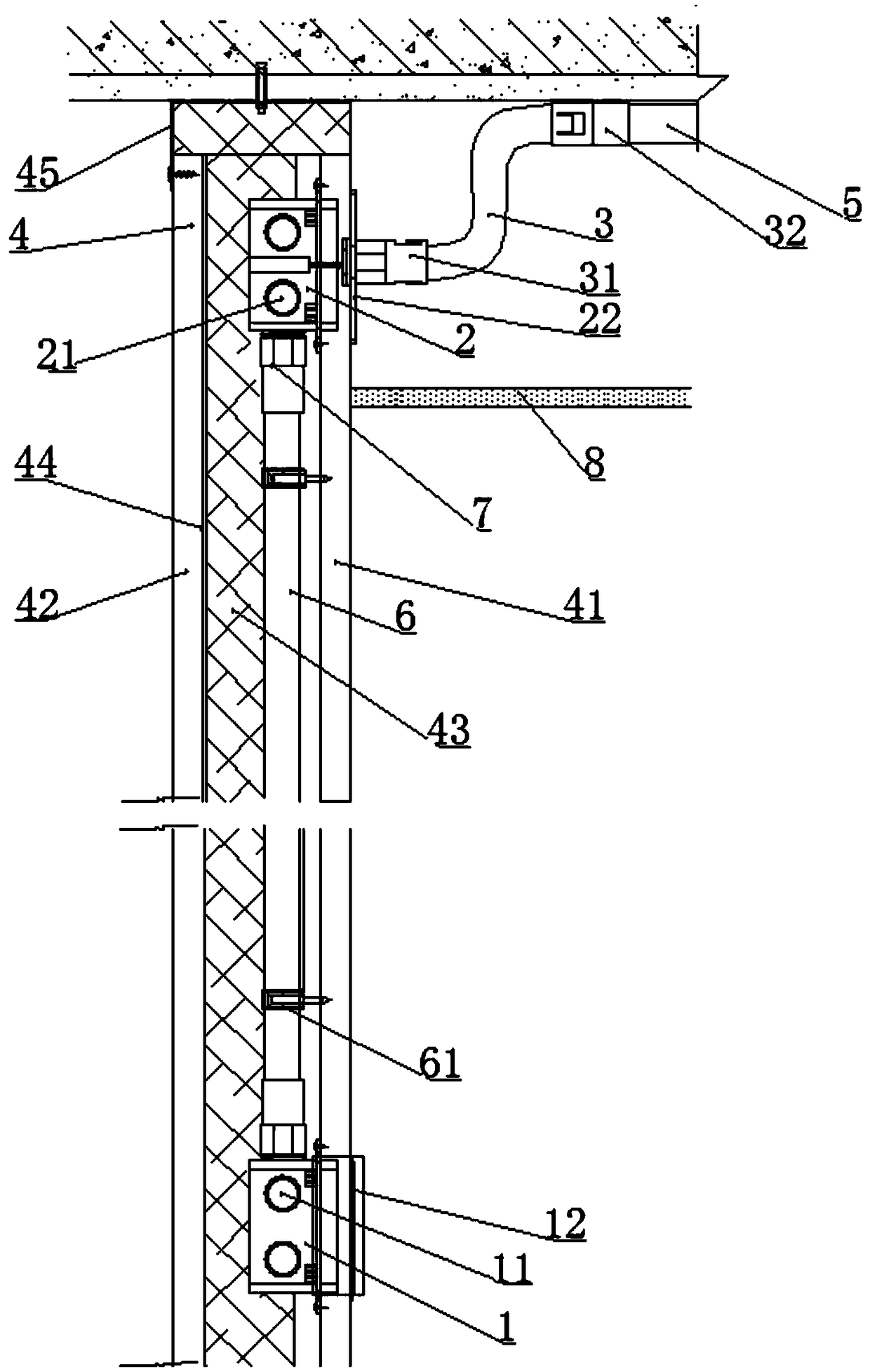

[0022] figure 1 A schematic structural diagram of a wiring device implemented in the present invention is shown, as figure 1 As shown, the wiring device provided by the embodiment of the present invention includes: a pipeline module integrated inside the partition wall 4 .

[0023] The pipeline module includes a first bottom box 1 , a second bottom box 2 , a panel 22 and a wiring pipe 6 for wiring. Wherein, the first bottom box 1 is installed in the first through hole of the partition wall 4 , the second bottom box 2 is installed in the second through hole of the partition wall 4 , and the wiring pipe 6 is installed in the partition wall 4 .

[0024] The first bottom box 1 is provided with a first installation hole 11, the second bottom box 2 is provided with a second installation hole 21, and the first installation hole 11 and the second installation hole 21 pass through the wiring duct 6 connections.

[0025] The panel 22 is covered on the second bottom box 2 , and the pa...

Embodiment 2

[0035] On the basis of the first embodiment above, optionally, as figure 1 As shown, the wiring device further includes: a cup comb 7 through which the wiring pipe 6 is respectively installed in the first installation hole and the second installation hole. By arranging the cup comb 7, damage to the electric wires can be prevented, repeated wiring can be avoided, and wiring efficiency can be improved.

[0036] Such as figure 1 As shown, the cup comb 7 connected to the second bottom box 2, the second bottom box 2, the hose 3, and the top line pipe 5 are all located between the suspended ceiling 8 and the ceiling, and the second bottom box 2 plays a certain transitional role. .

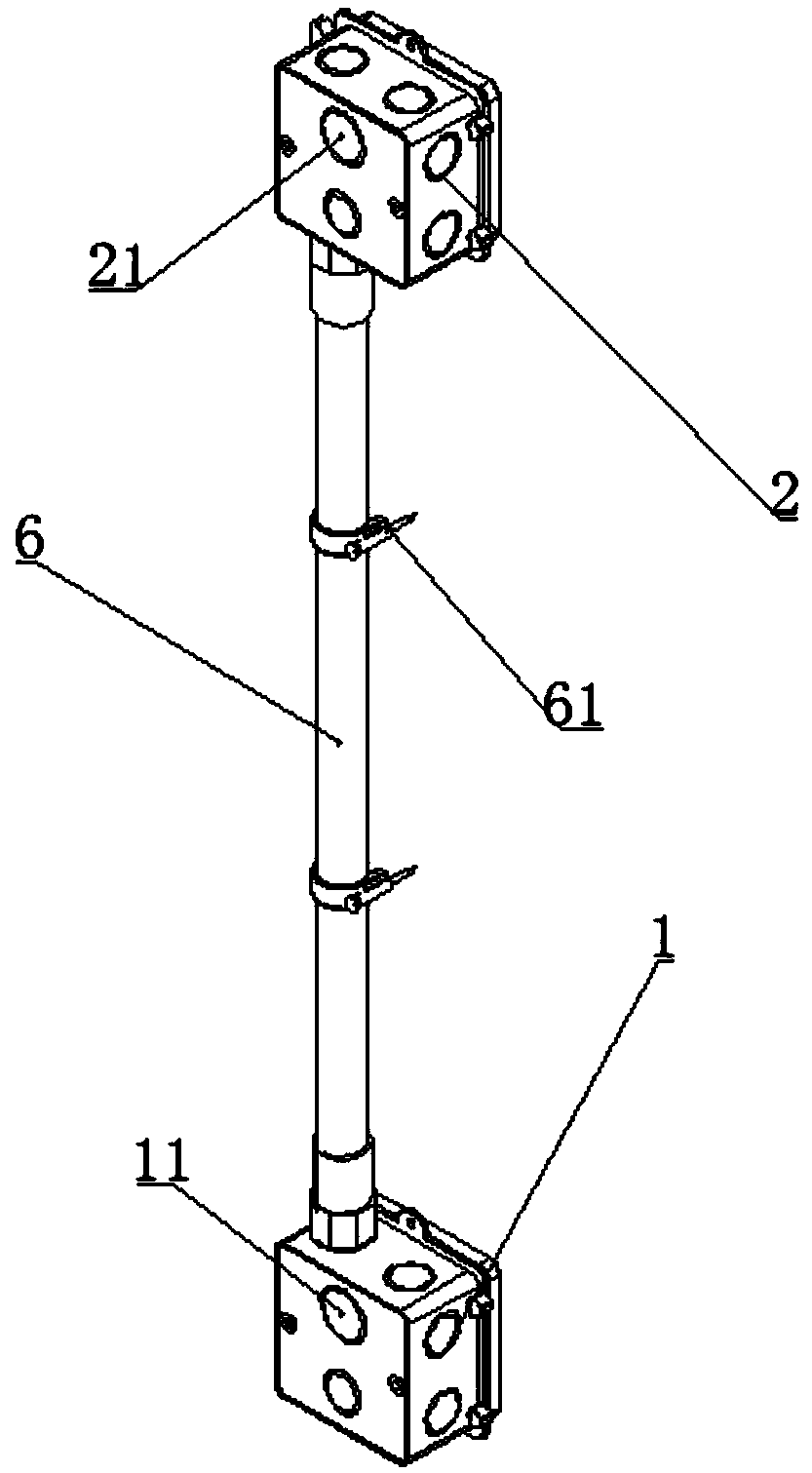

[0037] Further, as image 3 As shown, the wiring device further includes: a saddle card 61 , through which the wiring pipe 6 is fixed on the partition wall 4 , so as to ensure the installation firmness of the wiring pipe 6 .

[0038] Such as figure 1 As shown, the riding cards 61 are fixed on the in...

Embodiment 3

[0050] Based on the wiring device in Embodiment 1 or Embodiment 2, an embodiment of the present invention also provides a wiring method, which includes:

[0051] S110, installing the wiring pipe of the pipeline module in the partition wall;

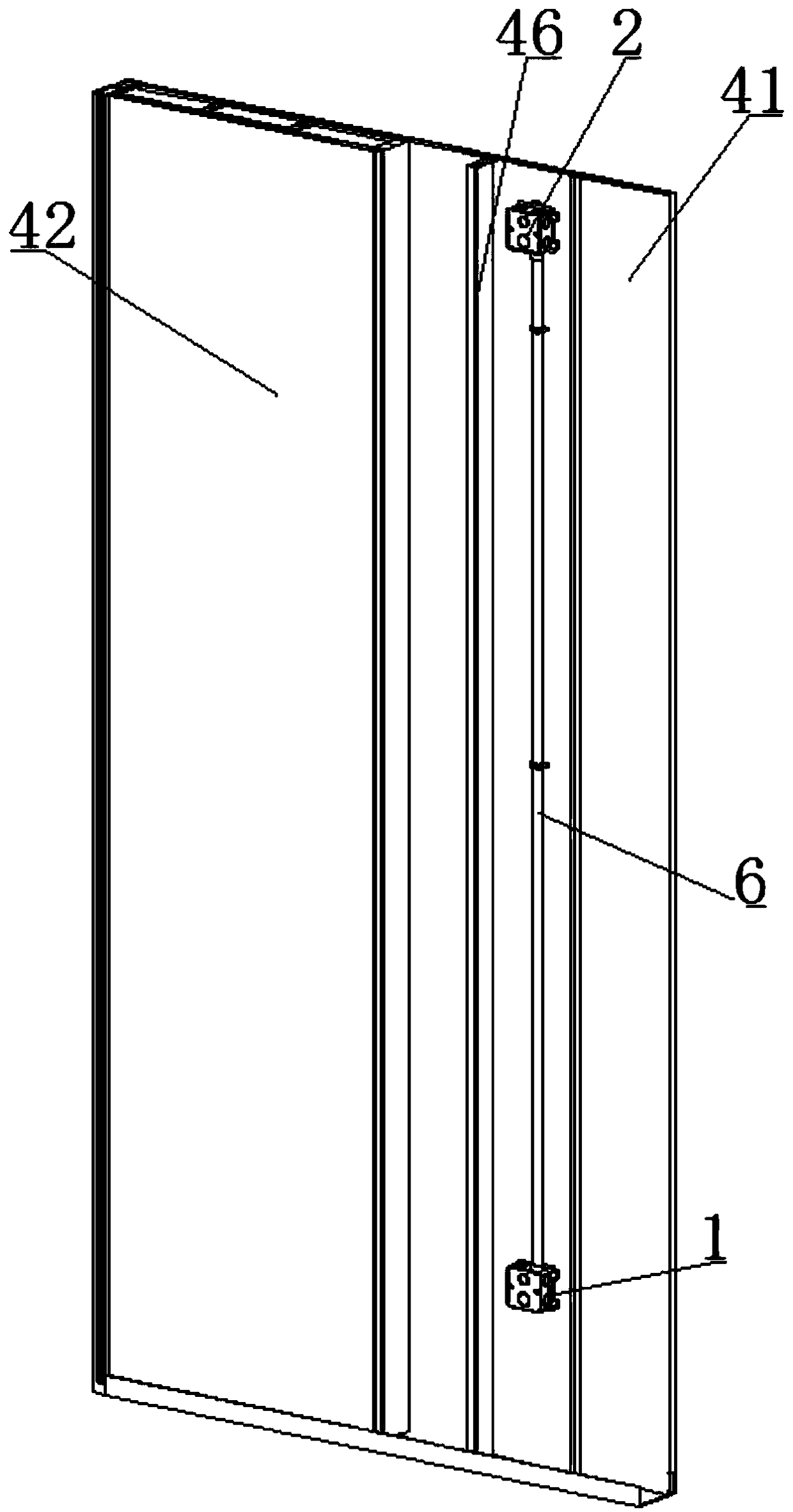

[0052] Such as figure 2 As shown, the pipeline modules are arranged between adjacent keels 45 of the partition wall 4 .

[0053] S120, respectively installing the first bottom box and the second bottom box in the first through hole and the second through hole of the partition wall;

[0054] Such as figure 1 As shown, both the first bottom box 1 and the second bottom box 2 are fixed on the first partition board 41 by fasteners. Fasteners can be screws, bolts and the like.

[0055] S130. Connect the first bottom box and the second bottom box to the wiring pipe respectively, and install the panel cover on the second bottom box.

[0056] Two ends of the wiring pipe 6 are inserted into the first installation hole 11 on the first bottom b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com