Feeding bottle capable of making milk powder quickly dissolved into milk

A milk powder and brewing technology, applied in feeding bottles, other household utensils, household components, etc., can solve problems such as deterioration of milk and troubles in brewing milk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

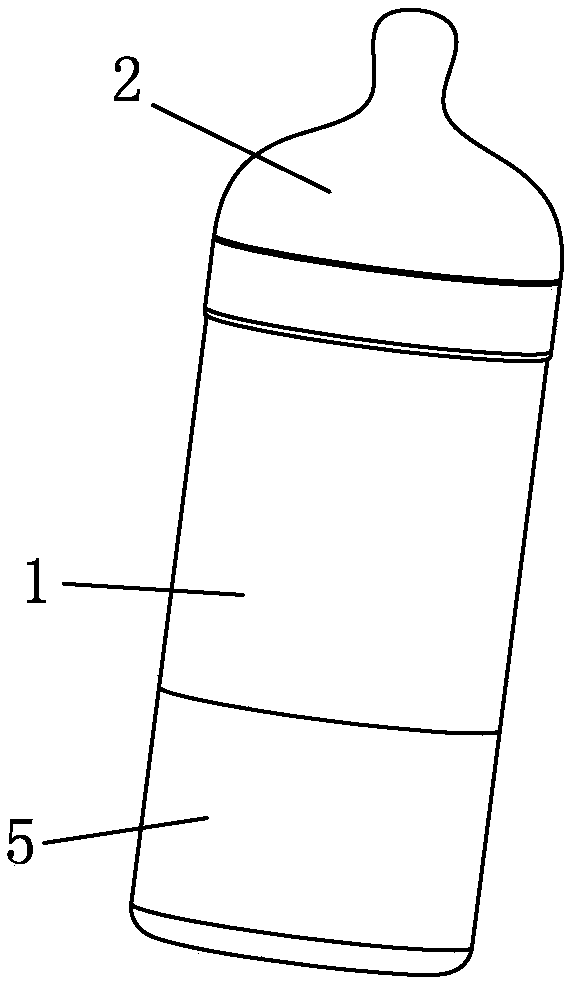

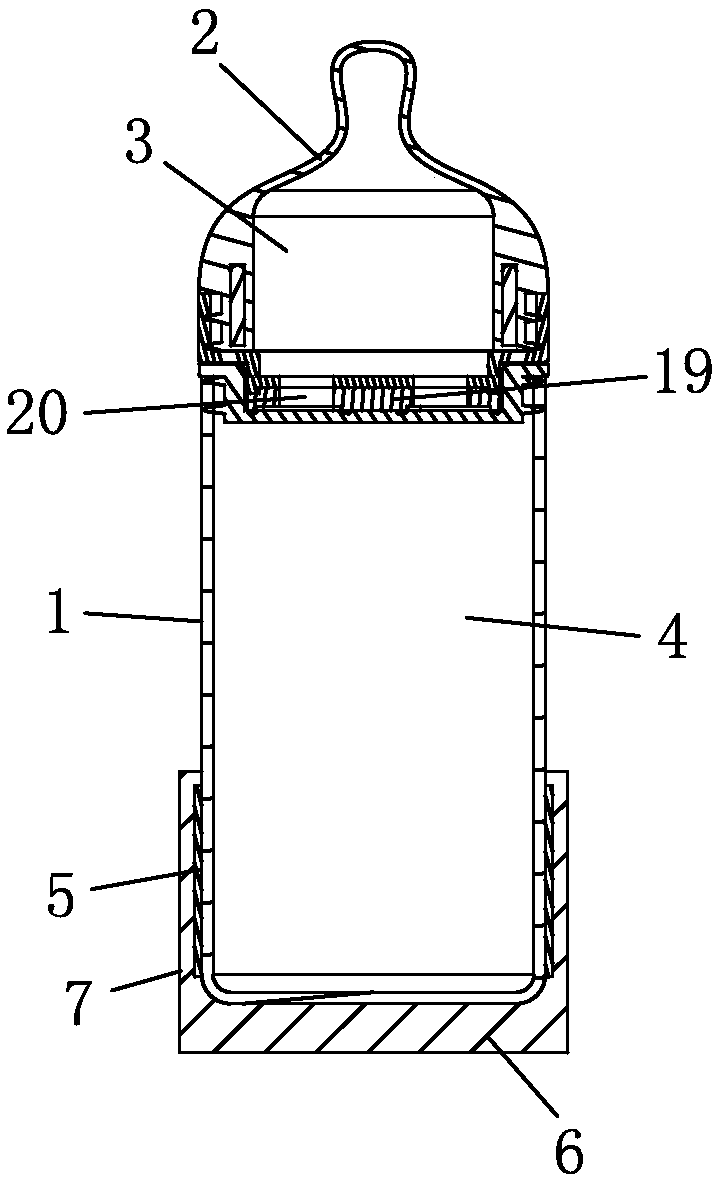

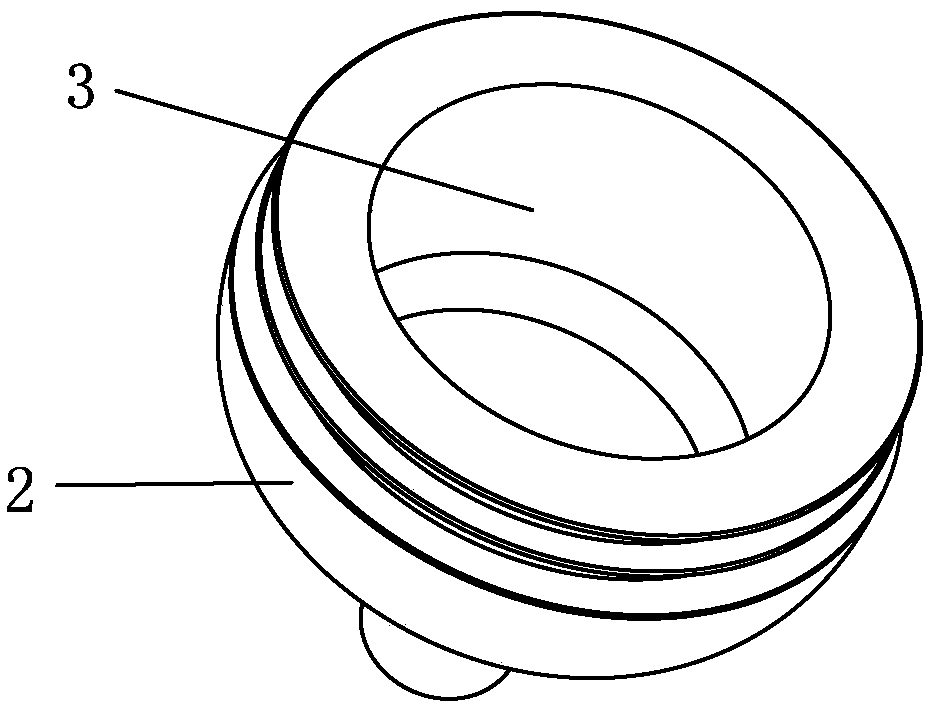

[0059] see Figure 1-Figure 3 , the feeding bottle that can quickly brew milk powder, including a bottle body 1 and a nipple 2 arranged on the bottle body 1, a switchable valve body assembly is provided between the bottle body 1 and the nipple 2, and the nipple 2 has a In the upper chamber 3 for storing milk powder, the upper chamber 3 penetrates downwards through the bottom of the nipple 2, the bottle body 1 has a lower chamber 4, and the lower chamber 4 penetrates upwards through the top of the bottle body 1, and the exterior of the bottle body 1 is equipped with an electric heater device 5;

[0060] When the valve body assembly is closed, the upper accommodating chamber 3 and the lower accommodating chamber 4 are not connected;

[0061] When the valve body assembly is opened, the upper accommodation chamber 3 communicates with the lower accommodation chamber 4 .

[0062] The pacifier 2 is provided with a bottle cap, and the bottle cap wraps the pacifier 2 inside, and the ...

no. 2 example

[0093] see Figure 3-Figure 12 , the feeding bottle that can quickly brew milk powder is different from the first embodiment in that the turntable includes a first bottom cylinder 10, the first bottom cylinder 10 is provided with a cavity passing through its upper part, and the feeding port 9 set on the bottom surface of the first bottom cylinder 10;

[0094] The horizontal section of the feed port 9 is fan-shaped, and there are two feed ports 9 oppositely arranged along the center of the bottom surface of the first bottom cylinder 10 .

[0095] The upper edge of the first bottom tube 10 extends horizontally outwards with a first annular portion 11 , and the outer edge of the first annular portion 11 extends vertically upwards with a first shroud 12 ;

[0096] The upper edge of the first shroud 12 extends horizontally outward with a second annular portion 13 , and the outer edge of the second annular portion 13 extends vertically upward with a second shroud 14 ;

[0097] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com