Minitype and efficient mechanical plate material automatic bending equipment

An efficient and mechanical technology, applied in the field of mechanical plate automatic bending equipment, can solve the problems of fastening efficiency reduction, device working efficiency reduction, inconvenient removal, etc., achieve good strong adsorption effect and reduce replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

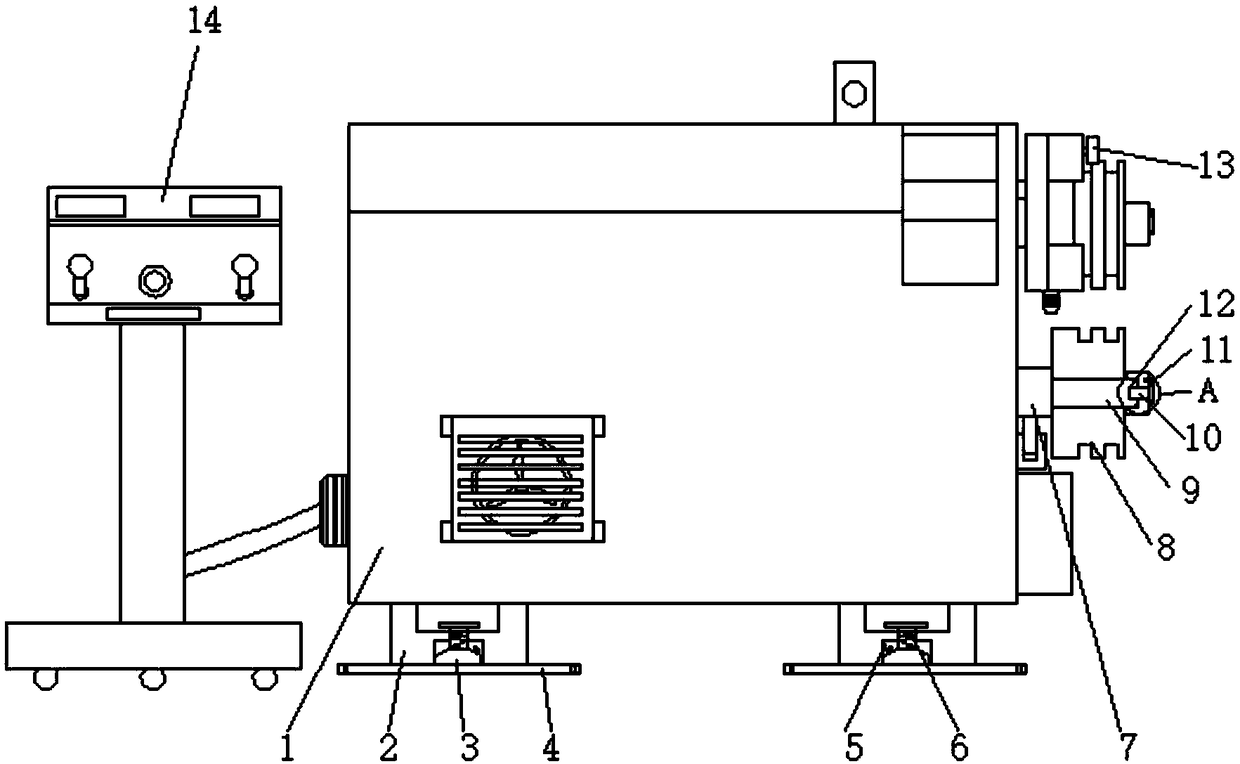

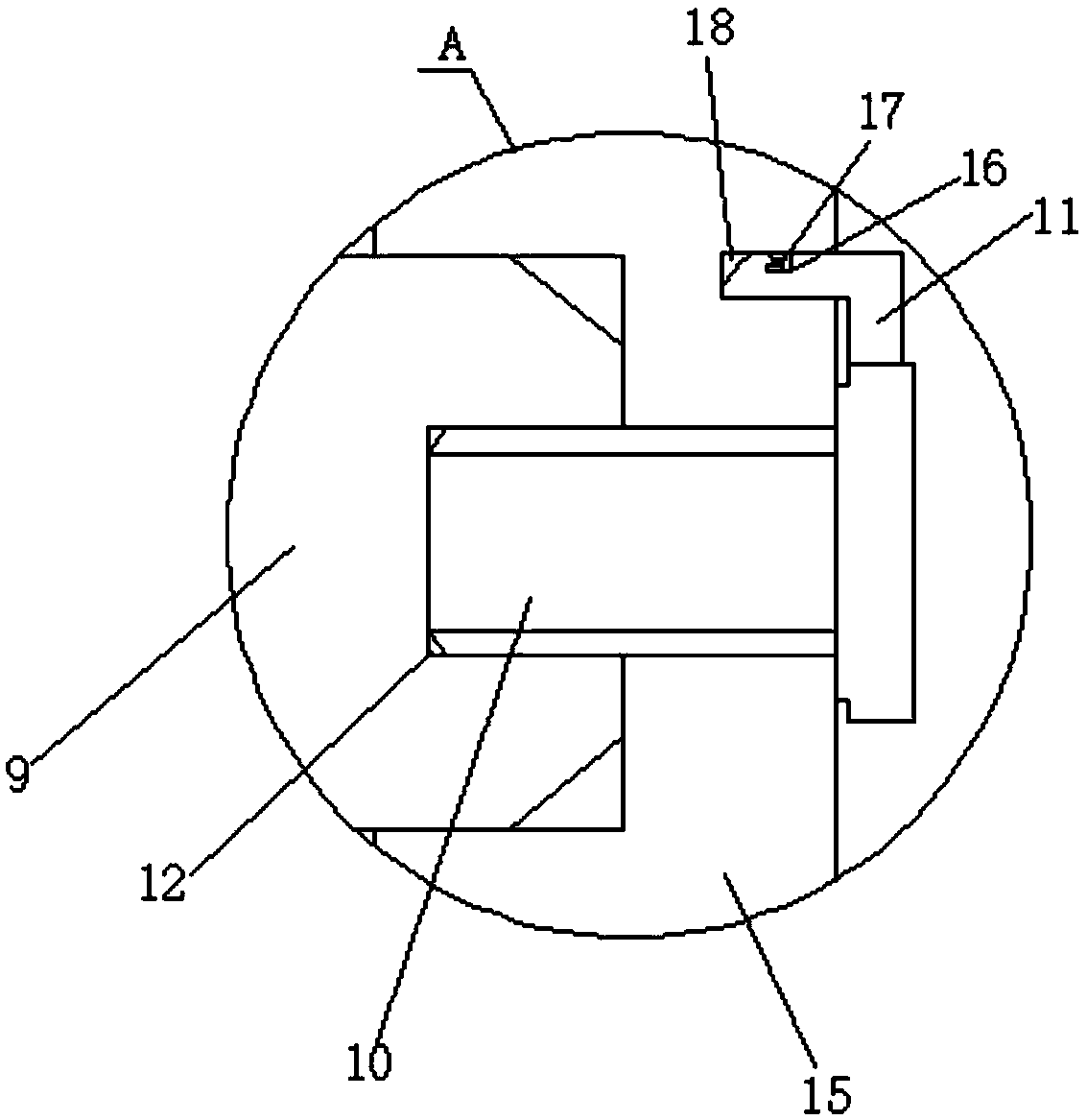

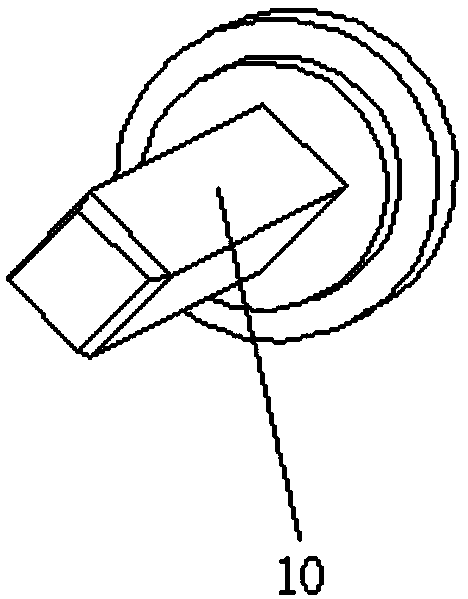

[0024] see Figure 1 to Figure 6 , the present invention provides a technical solution: a small and efficient automatic bending equipment for mechanical plates, including an outer casing 1, a shaft sleeve 7 is arranged on the front surface of the outer casing 1, and a shaft 9 is sleeved inside the shaft sleeve 7, and the shaft 9 The outer wall is sleeved with a rotating roller 8, and the center of the end of the rotating roller 8 is fixed with a fixed block 15. The inner wall of the fixed block 15 and the outer wall of the shaft 9 are attached to each other. The surface of the shaft 9 is provided with a square groove 12, and the surface of the fixed block 15 is provided with a Square hole, the inside of the square hole is provided with a fixed rod 10, through the design of the fixed rod 10, the shape of the fixed rod 10 is square, so that it can be engaged and fixed with the square groove 12 on the end of the shaft rod 9, so that the shaft rod 9 is connected with the rotating ...

Embodiment 2

[0026] see Figure 1 to Figure 7 , the present invention provides a technical solution: a small and efficient automatic bending equipment for mechanical plates, including an outer casing 1, a shaft sleeve 7 is arranged on the front surface of the outer casing 1, and a shaft 9 is sleeved inside the shaft sleeve 7, and the shaft 9 The outer wall is sleeved with a rotating roller 8, and the center of the end of the rotating roller 8 is fixed with a fixed block 15. The inner wall of the fixed block 15 and the outer wall of the shaft 9 are attached to each other. The surface of the shaft 9 is provided with a square groove 12, and the surface of the fixed block 15 is provided with a Square hole, the inside of the square hole is provided with a fixed rod 10, through the design of the fixed rod 10, the shape of the fixed rod 10 is square, so that it can be engaged and fixed with the square groove 12 on the end of the shaft rod 9, so that the shaft rod 9 is connected with the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com