Insertingmagnetic steelriveting press

A technology of riveting machine and magnetic insertion, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of large magnetism, complicated adjustment, and difficult assembly of magnetic steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

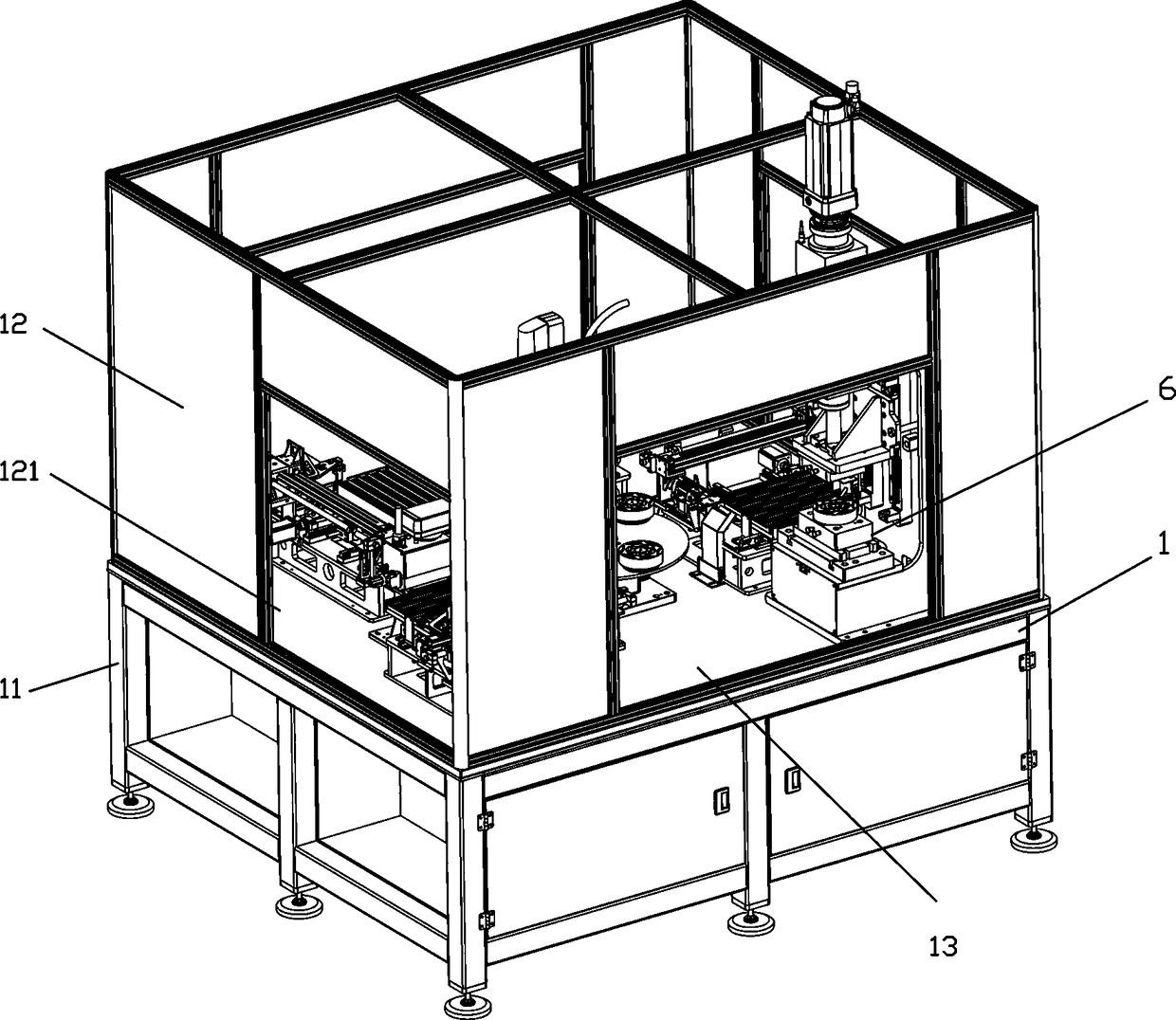

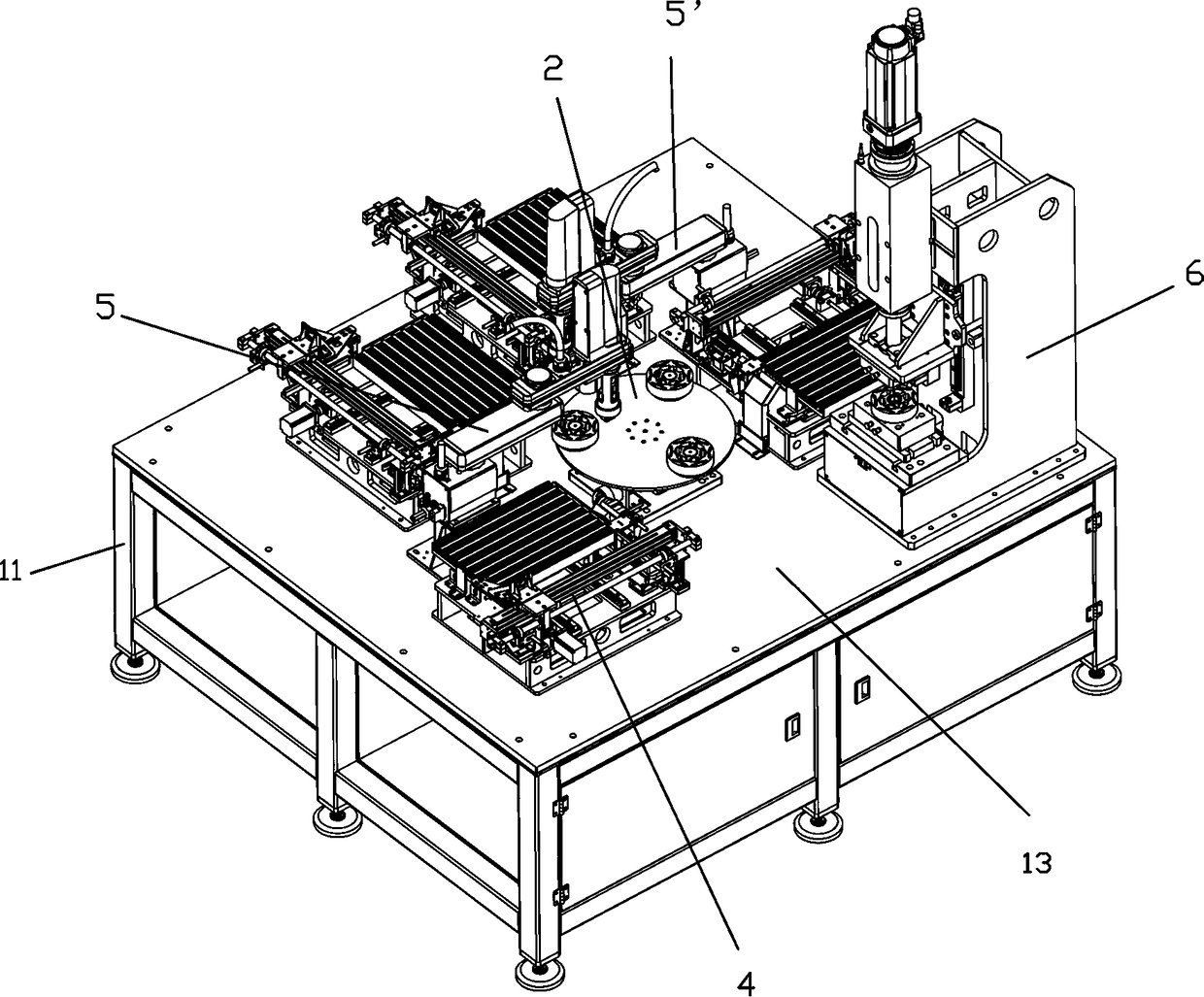

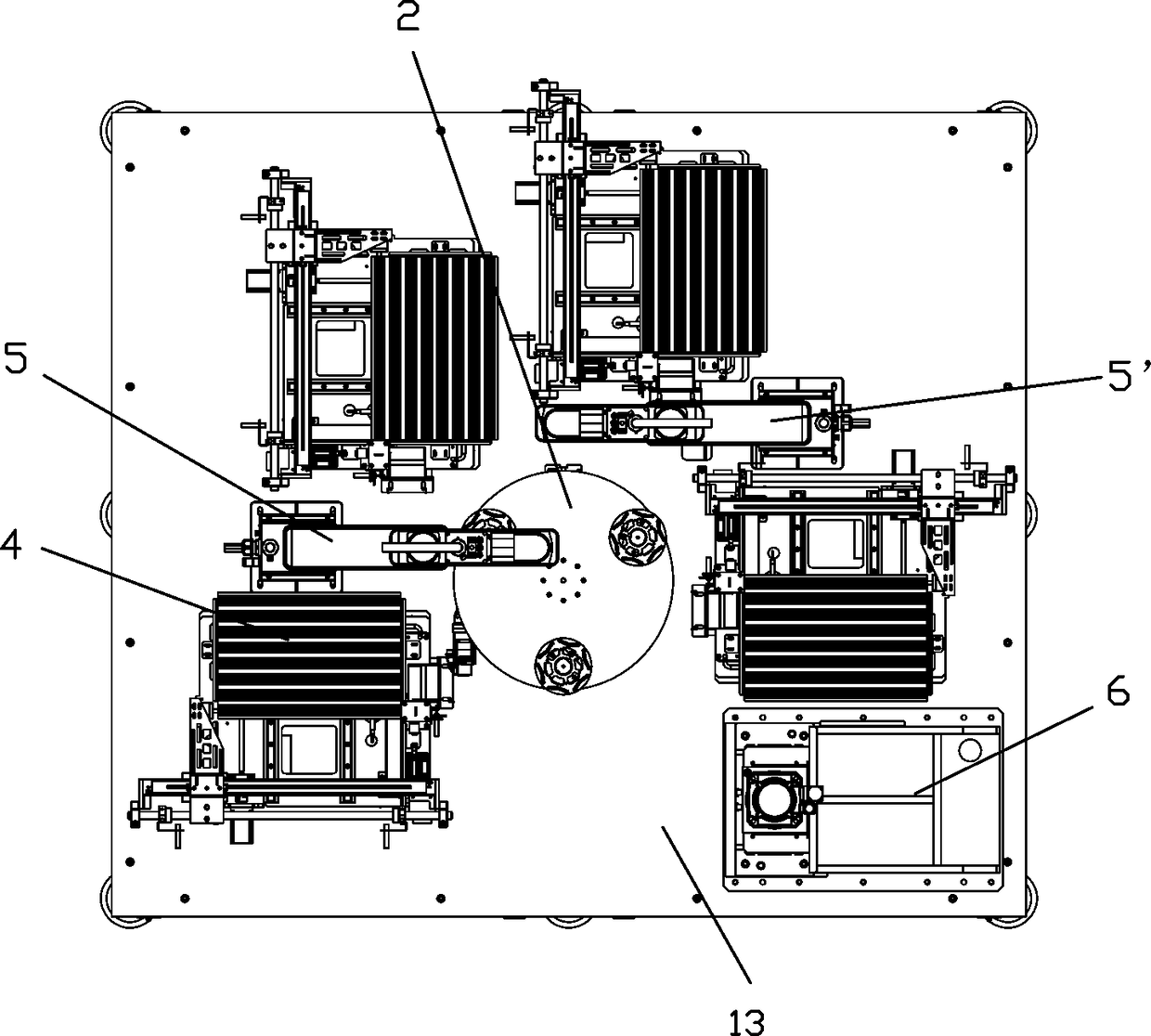

[0022] see Figure 1 to Figure 5 , a magnetic steel riveting machine of the present invention, which includes,

[0023] The frame 1 includes a fixed frame 11 and its upper side plate 12, a working platform 13 is arranged horizontally in the middle of it, and a workpiece entry and exit window 121 is set on the side plate 12;

[0024] The rotary table 2 is arranged in the center of the working platform 13 through a rotating shaft;

[0025] The rotating motor 3 is arranged on the working platform 13, and is connected to the rotating shaft through a cam divider structure, and drives the rotating table 2 to rotate;

[0026] Four workpiece tables 4 (taking the workpiece table 4 as an example, the same below), are arranged around the circumference of the rotary table 2;

[0027] Two manipulators 5, 5' are respectively arranged on both sides of the rotary table 2, and are respectively located between the left and right workpiece tables 4;

[0028] The riveting device 6 is set on a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap