Full-automatic pipe sleeving machine

A casing machine, fully automatic technology, applied in the direction of electrical components, circuits, marking conductors/cables, etc., can solve the problems of slow manual assembly, elimination, low casing efficiency, etc., to meet assembly requirements, improve service life, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

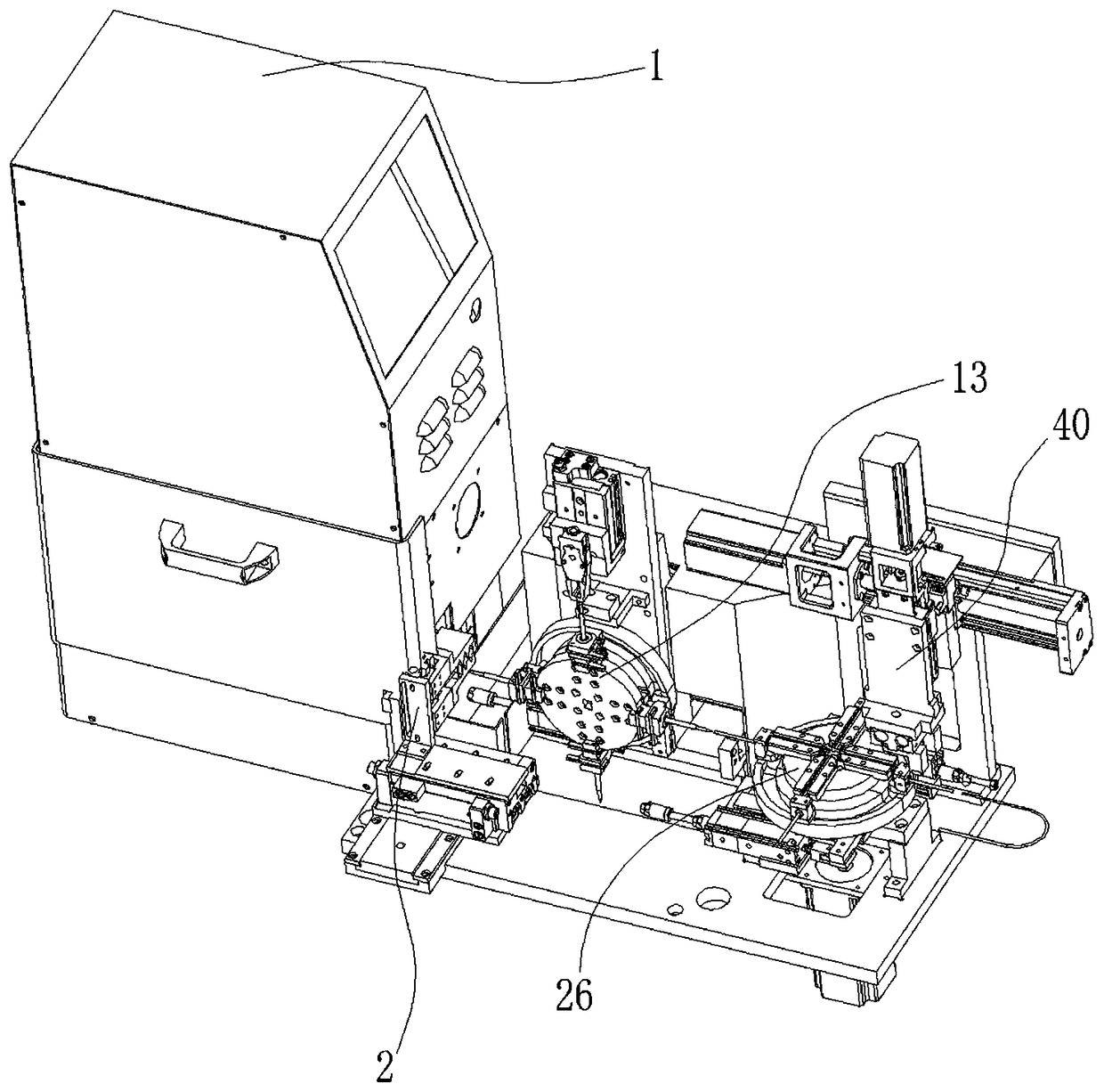

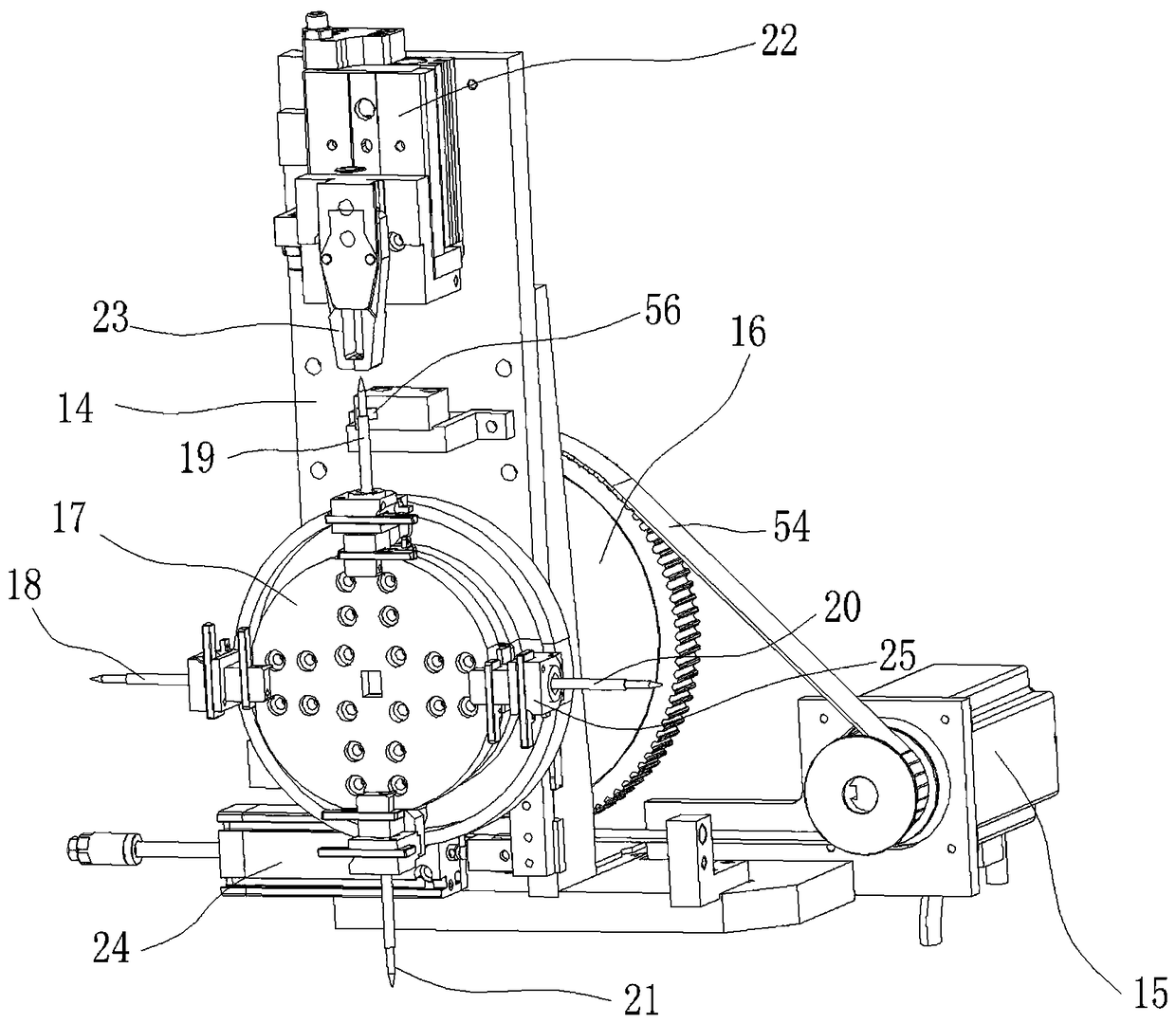

[0026] refer to Figure 1 to Figure 5 , a fully automatic casing machine, comprising:

[0027] casing cutting machine 1, which is used to cut the output casing into uniform length;

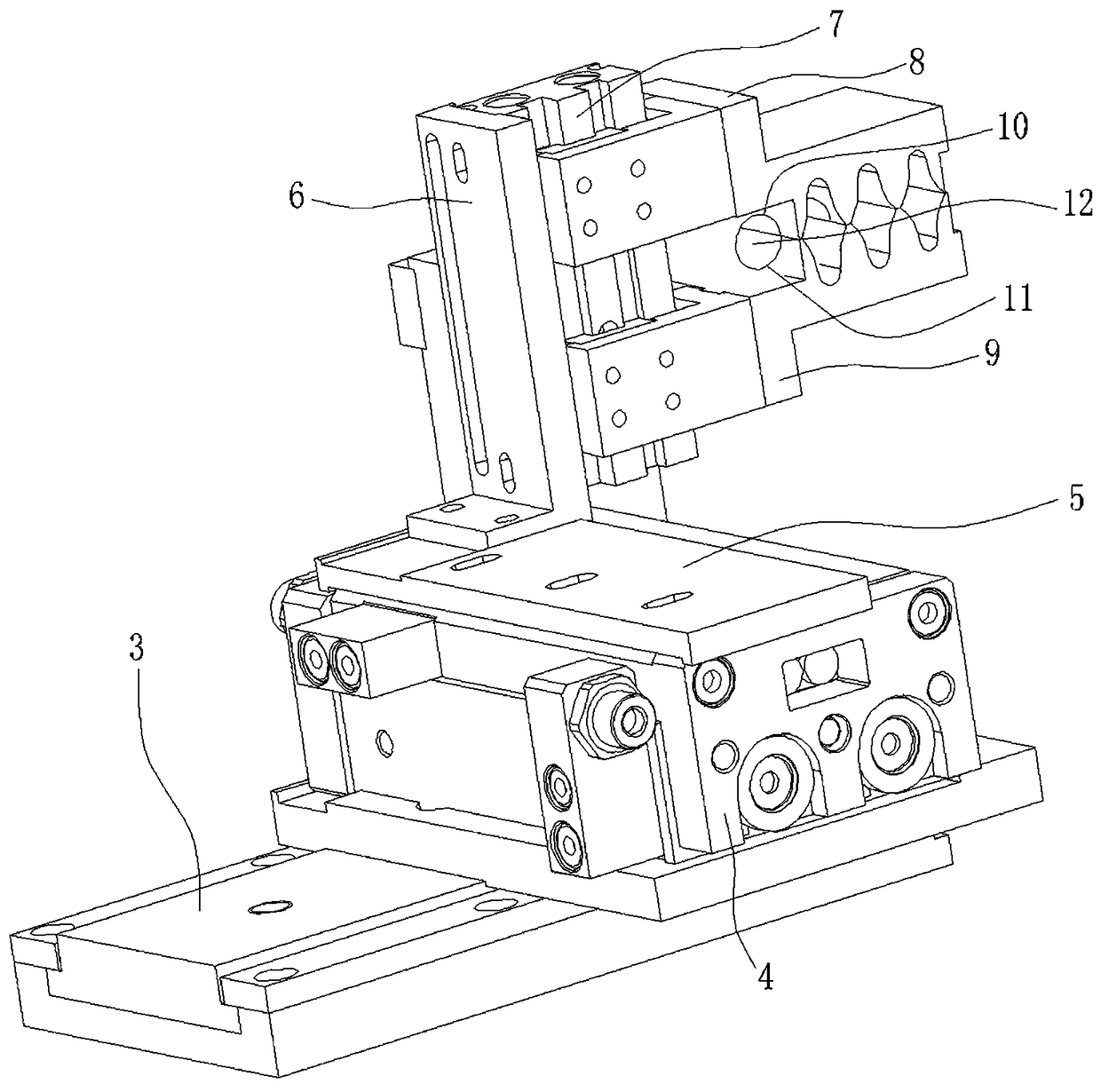

[0028] refer to figure 2 , the first conveying mechanism 2, which is used to convey the casing output by the casing cutting machine, includes a first conveying bracket 3, and the first conveying bracket 3 is provided with a first conveying module 4, and the described The first conveying module 4 is connected with a first conveying slider 5, and the first conveying slider 5 is horizontally provided with a fixed bracket 6, and the described fixed bracket 6 is provided with a first sliding module 7, and the described fixed bracket 6 is provided with a first sliding module 7. The first sliding module 7 is provided with a first clamping block 8 and a secon...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap