A round steel pipe welding machine

A technology for round steel pipes and welding machines, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficult round steel pipes in synchronous motion state, affecting the reliability of welding joints, and unreliable welding joints, etc., to achieve Simple and convenient adjustment, improved welding efficiency and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. In addition, it should be understood that after reading the content taught by the present invention, those skilled in the art may make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined in the present application.

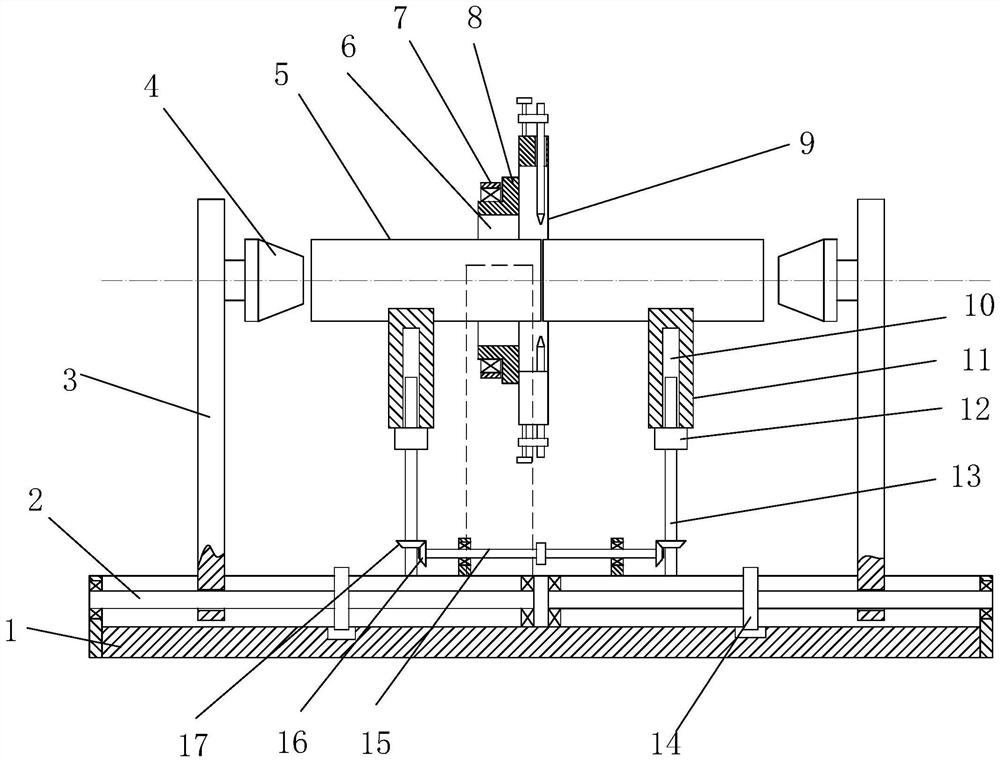

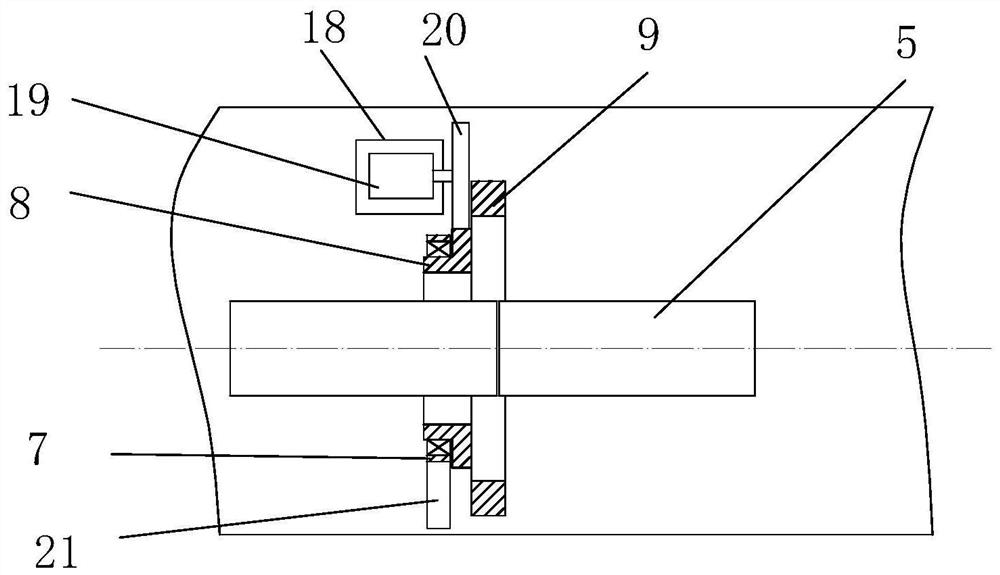

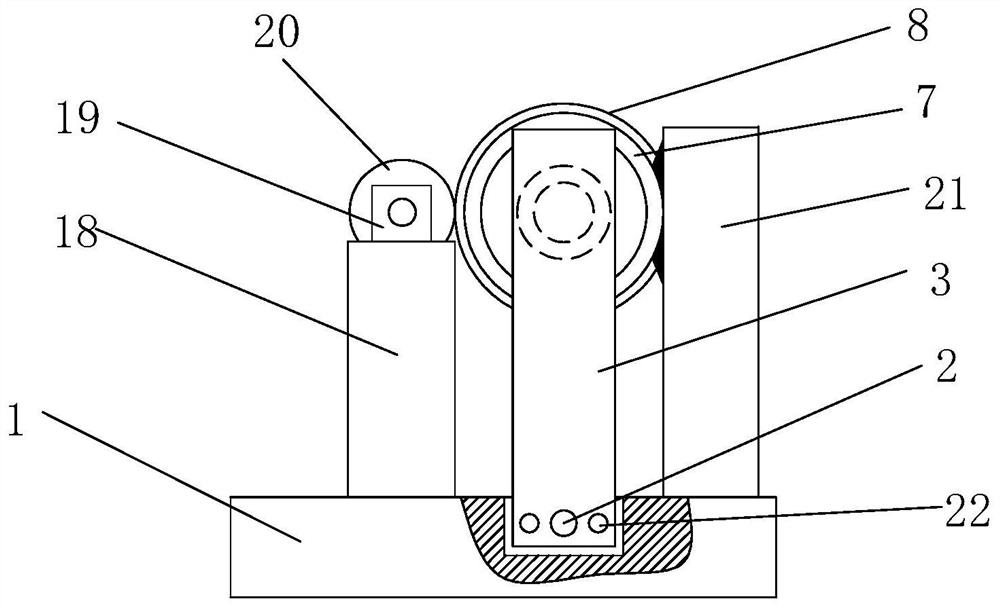

[0022] like Figure 1~5 As described above, a round steel pipe welding machine includes a base 1 on which a support mechanism, a tightening mechanism and a welding mechanism are arranged. The support mechanism includes two support seats 11, and a support drive assembly is arranged under the support seats 11. Two The support base 11 can be lifted vertically under the control of the support drive assembly. The jacki...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap