Carbon brush box of windshield wiper motor and windshield wiper motor assembly

A technology of motor components and carbon brushes, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of inconvenient installation of torsion springs, difficulty in installing torsion springs in place, easy installation of torsion springs and being stuck in place, and achieve the goal of installation The effect of convenient torsion spring and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

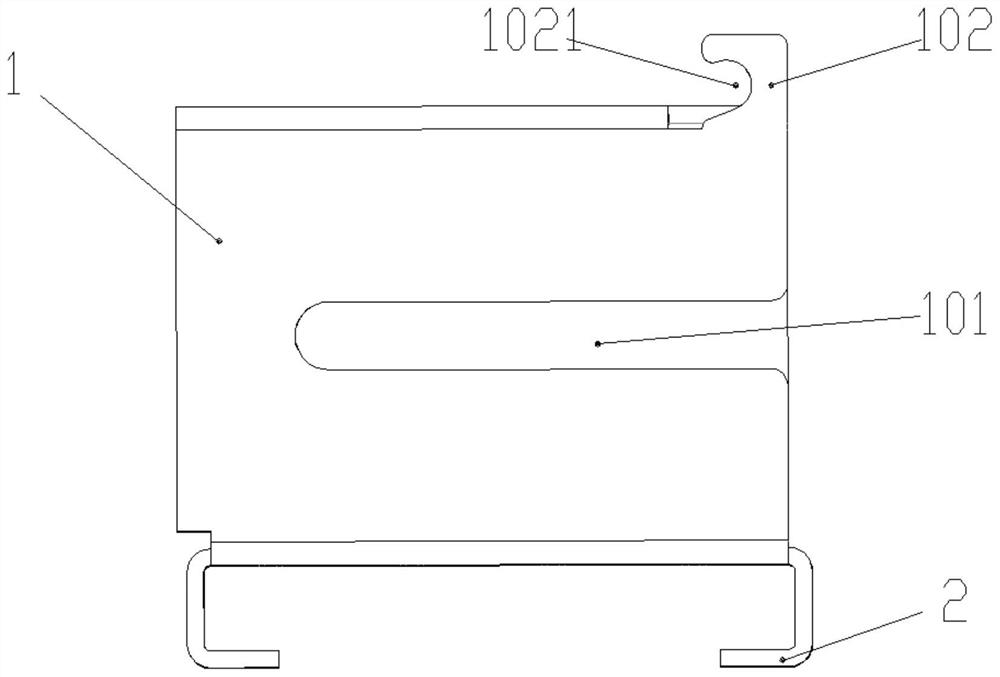

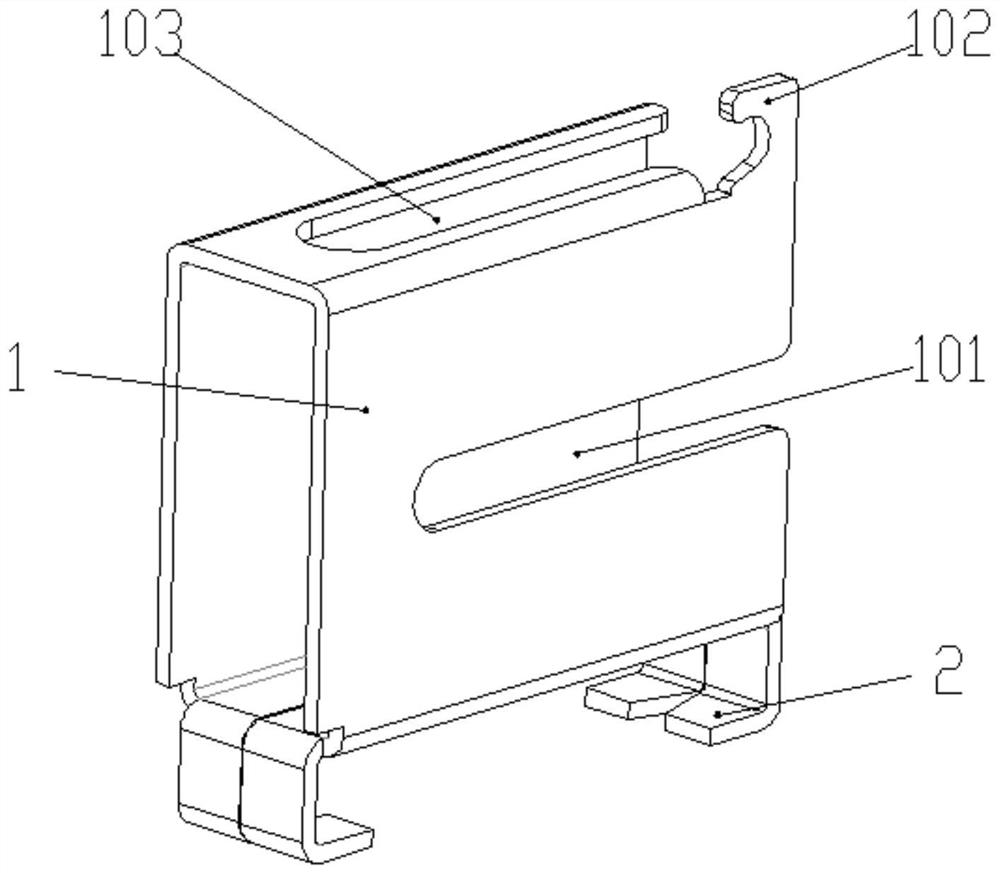

[0016] like figure 1 and figure 2 As shown, the wiper motor carbon brush box includes a box body 1, the top of the box body 1 is provided with a brush braid groove 103, and the top of the side wall of the torsion spring groove 101 is provided with an ear plate 102 on the box body 1, and the ear plate 102 is arranged on the top of the box body 1. The plate 102 is coplanar with the side wall provided with the torsion spring slot 101 , and the ear plate 102 is provided with a notch 1021 facing the outlet of the carbon brush.

[0017] In order to facilitate fixing the box body 1 on the circuit board, two claws 2 are provided at the bottom of the box body 1, and the two claws 2 are bent towards each other, forming a circuit board fixing position between the claws 2 and the box body 1,

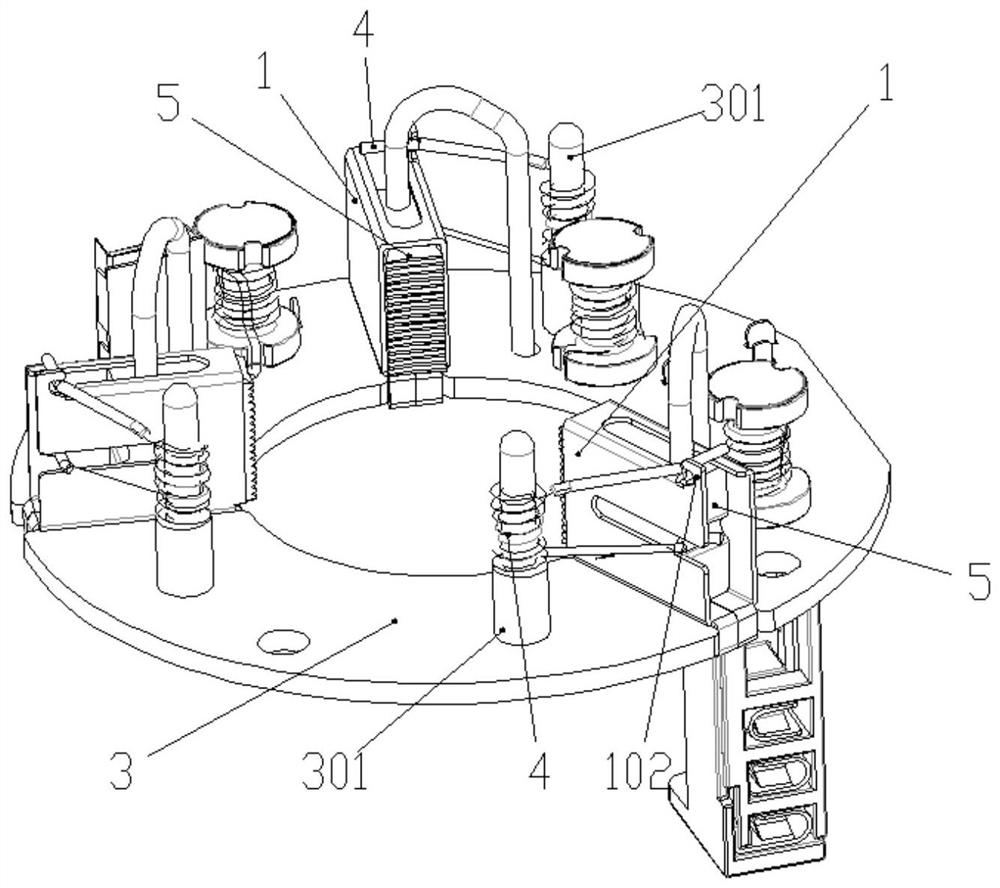

[0018] like image 3 As shown, the wiper motor assembly includes a circuit board 3, a car...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap