wood processing equipment

A technology for processing equipment and wood strips, which is applied in the direction of wood processing equipment, sawing equipment, manufacturing tools, etc. It can solve the problems that the processing quality cannot be guaranteed, cannot be separated from manual operation, and the processing method cannot meet the needs, so as to improve work efficiency. , The effect of improving the processing quality and protecting the processing environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

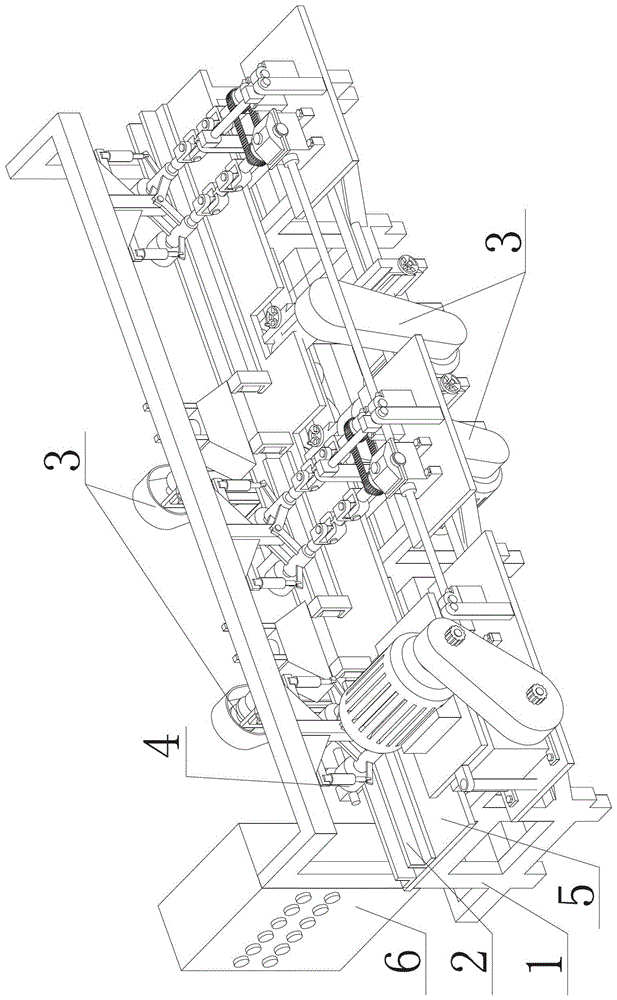

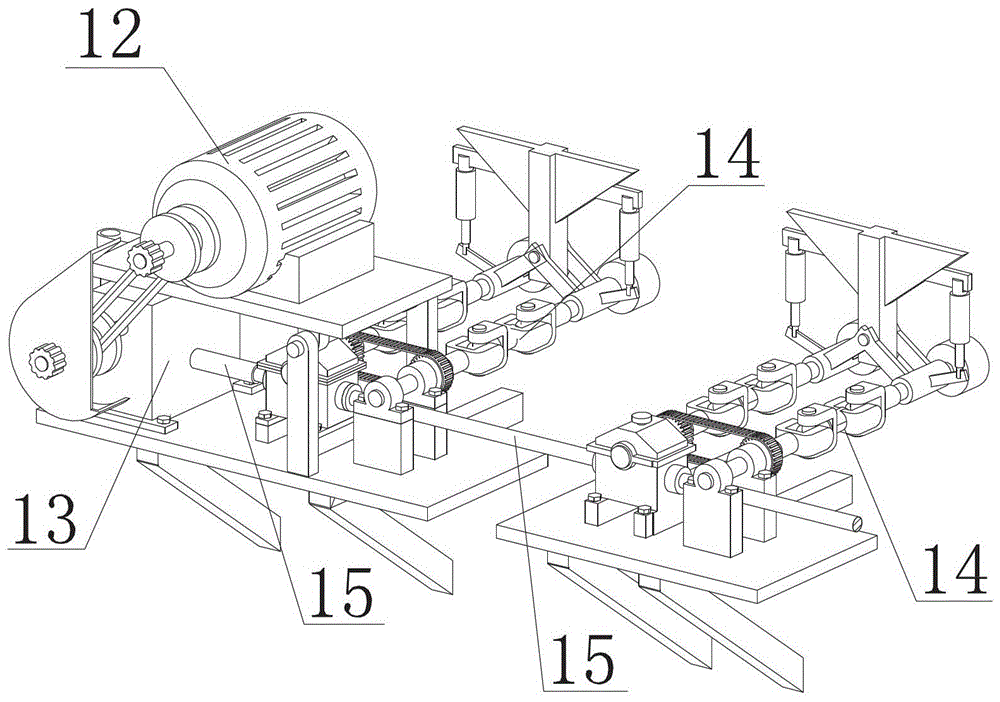

[0029] Embodiment 1 of the present invention: a kind of strip processing equipment, such as figure 1 As shown, it includes a frame 1, a wooden strip walking track 2, an adjustable cutting device 3 and a pressing transmission device 4. The wooden strip walking track 2 is arranged on the middle support platform 5 of the frame 1, directly above the wooden strip walking track 2 There is a pressing conveying device 4, three adjustable cutting devices 3 are respectively arranged on both sides of the wooden strip walking track 2, and an electric control box 6 is arranged at one end of the frame 1, and the electric control box 6 is connected with the adjustable cutting device 3 and the The press delivery device 4 is electrically connected.

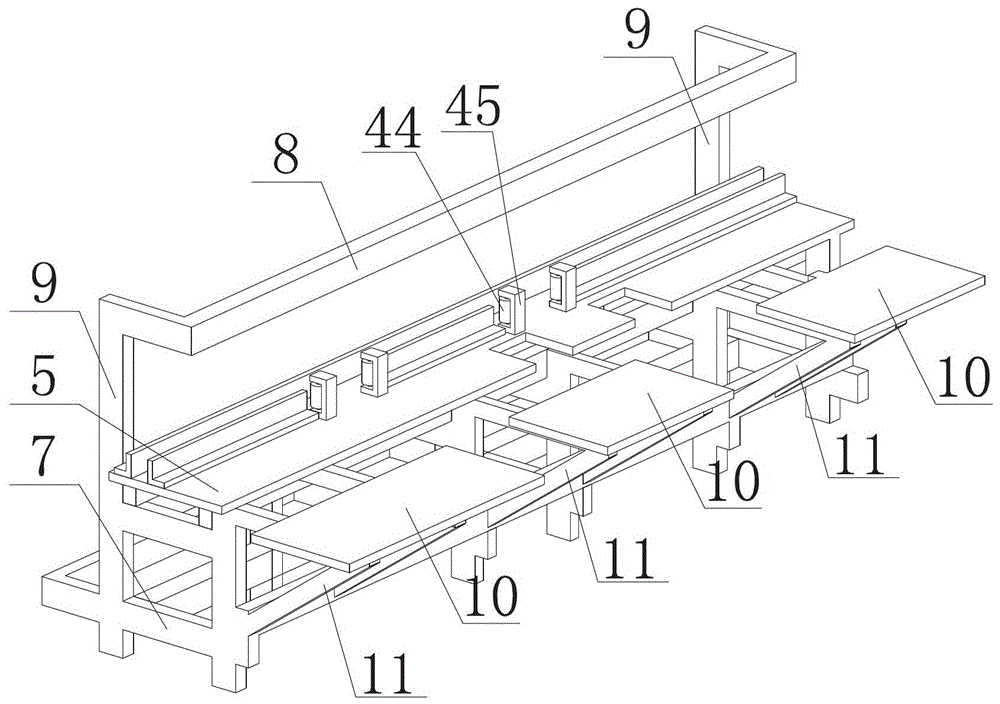

[0030] Such as figure 2 As shown, the frame 1 includes a middle support platform 5, a bottom support platform 7, a top suspension beam 8 and a main support rod 9, and the bottom support platform 7 and the middle support platform 5 are fixedly co...

Embodiment 2

[0038] Embodiment 2 of the present invention: The difference between this embodiment and Embodiment 1 is that five adjustable cutting devices 3 are respectively provided on both sides of the wooden strip walking track 2; 10 side supports are provided on one side of the central support platform 5 Platform 10.

Embodiment 3

[0039] Embodiment 3 of the present invention: The difference between this embodiment and Embodiment 1 is that an adjustable cutting device 3 is provided on both sides of the wooden strip walking track 2; a side support is provided on one side of the central support platform 5 Platform 10.

[0040] The working principle of the present invention: first adjust the wooden strip walking track 2 according to the width of the wooden strip, the adjustment method is: loosen the bolt 48 on the "L" shaped angle iron 46, then move the "L" shaped angle iron 46, when two " After the distance between the L "shaped angle irons 46 is properly adjusted, tighten the bolts 48.

[0041] Then adjust the inclination angle of the cutting saw blade 33 according to the angle between the hypotenuse and the bottom edge of the triangular wood strip to be processed. The specific adjustment method is: when the height of the cutting saw blade 33 needs to be adjusted, rotate the vertical adjustment screw 53,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap