Repeatable lifting plug-in device

A plug-in device and plug-board technology, which is applied to the components of the connection device, coupling devices, connections, etc., can solve the problems of high cost and poor quality of joints that are difficult to adapt to product production, research and development, and testing, and achieve improved testing Quality and effect, improved service life, effect of low contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

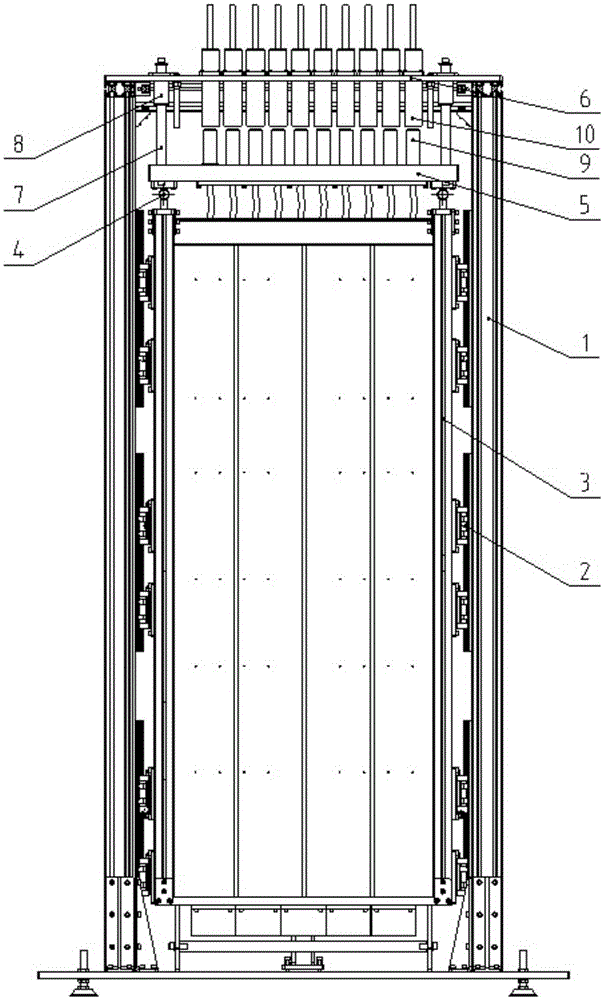

[0019] Such as figure 1 As shown, a plug-in device that can be repeatedly lifted and lowered includes a frame 1 and an up and down moving unit 3 that is arranged on the frame 1 and can move up and down. The upper end of the up and down moving unit 3 is provided with a plug plate 5, and The socket board 6, the plug board 5 and the socket board 6 are mated and inserted. The plug plate 5 is provided with a plurality of plug columns 9 , and the socket plate 6 is provided with socket slots 10 corresponding to the plug columns 9 . In this embodiment, the plug post 9 of the plug board 5 and the socket groove 10 of the socket board 6 are inserted into each other. The disassembly and assembly of the two parts can be realized; when assembling, it is only necessary to insert the plug column 9 of the plug board 5 into the socket groove 10 of the socket board 6 . The plugging control between the plug board 5 and the socket board 6 is realized by the up and down moving unit 3, and the up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com