Plywood cutting equipment

A technology for cutting equipment and plywood, applied to other plywood/plywood appliances, wooden veneer joints, wood processing appliances, etc., can solve the problems of worker injury, waste of manpower and material resources, and unfavorable production efficiency, so as to ensure safety and operation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

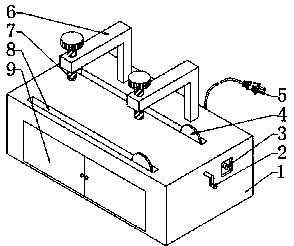

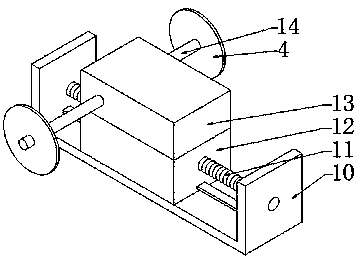

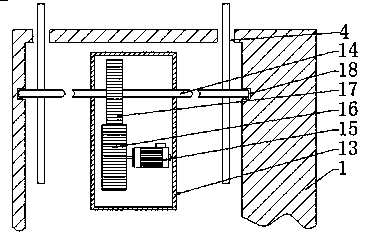

[0020] Example: such as figure 1 , figure 2 and image 3 As shown, a plywood cutting equipment of the present invention comprises a box body 1 and a guide rail frame 10, the two sides of the guide rail frame 10 are fixedly connected with the two sides of the inner wall of the box body 1 one by one, and the back side of the box body 1 is fixedly provided with a plug 5 One side of the box body 1 is provided with a handle 2, one side of the box body 1 and next to the handle 2 is embedded with a button switch 3, the top of the box body 1 is provided with two opening slots 8, and the inside of the box body 1 Both the front and the back are provided with chute 18, and two fixed frames 6 are fixed on one side of the top of the box body 1 near the rear, and one end of the two fixed frames 6 is provided with screw holes, and the internal threads of the screw holes are connected with bolts. 7. The top of the guide rail frame 10 is provided with a slider 12 through the movement of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap