Inner core of triangular arm

A triangular arm and inner core technology, which is applied to the cantilever mounted on the pivot, suspension, transportation and packaging, etc., can solve the problem that the service life of the triangular arm is shortened, the normal driving and driving safety of the driver are affected, and the inner core is easily damaged. and other problems to achieve the effect of reducing hard collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

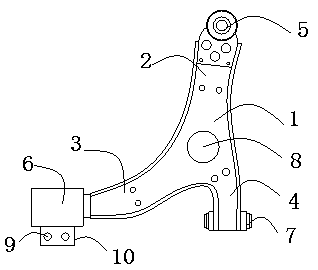

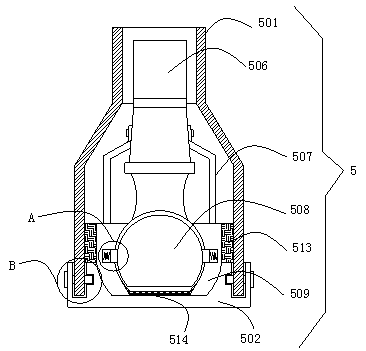

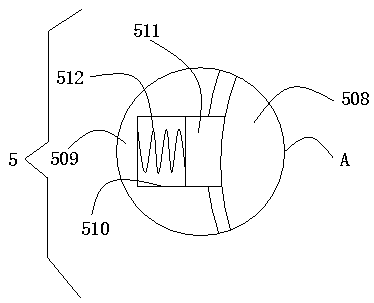

[0020] Such as Figure 1-4 As shown, the inner core of a triangular arm includes a triangular arm body 1, a first arm body 2, a second arm body 3, a third arm body 4, a ball head device 5, a first rubber bushing 6 and a second rubber bushing Bushing 7, the first arm body 2 is located above the triangular arm body 1, the second arm body 3 is located on the left side of the triangular arm body 1, the third arm body 4 is located on the right side of the triangular arm body 1, and the ball head device 5 is fixed Installed above the first arm body 2, the first rubber bushing 6 is fixedly installed on the left side of the second arm body 3. A large number of rubber bushings are used in the suspension of modern cars to meet the needs of vehicle vibration and noise reduction. The precise design of the frame also requires the matching of various performance parameters of the rubber bushing. The commonly used rubber bushing is composed of an intermediate rubber body and a metal sleeve. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com