Overturning device for vertical-stacked precast concrete wallboards

A prefabricated concrete and flipping device technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of cracking of the lower wallboard, increase the workload of on-site lifting, and reduce the efficiency of on-site construction, so as to achieve fast hoisting speed and guarantee the wallboard The effect of quality, improvement of engineering efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

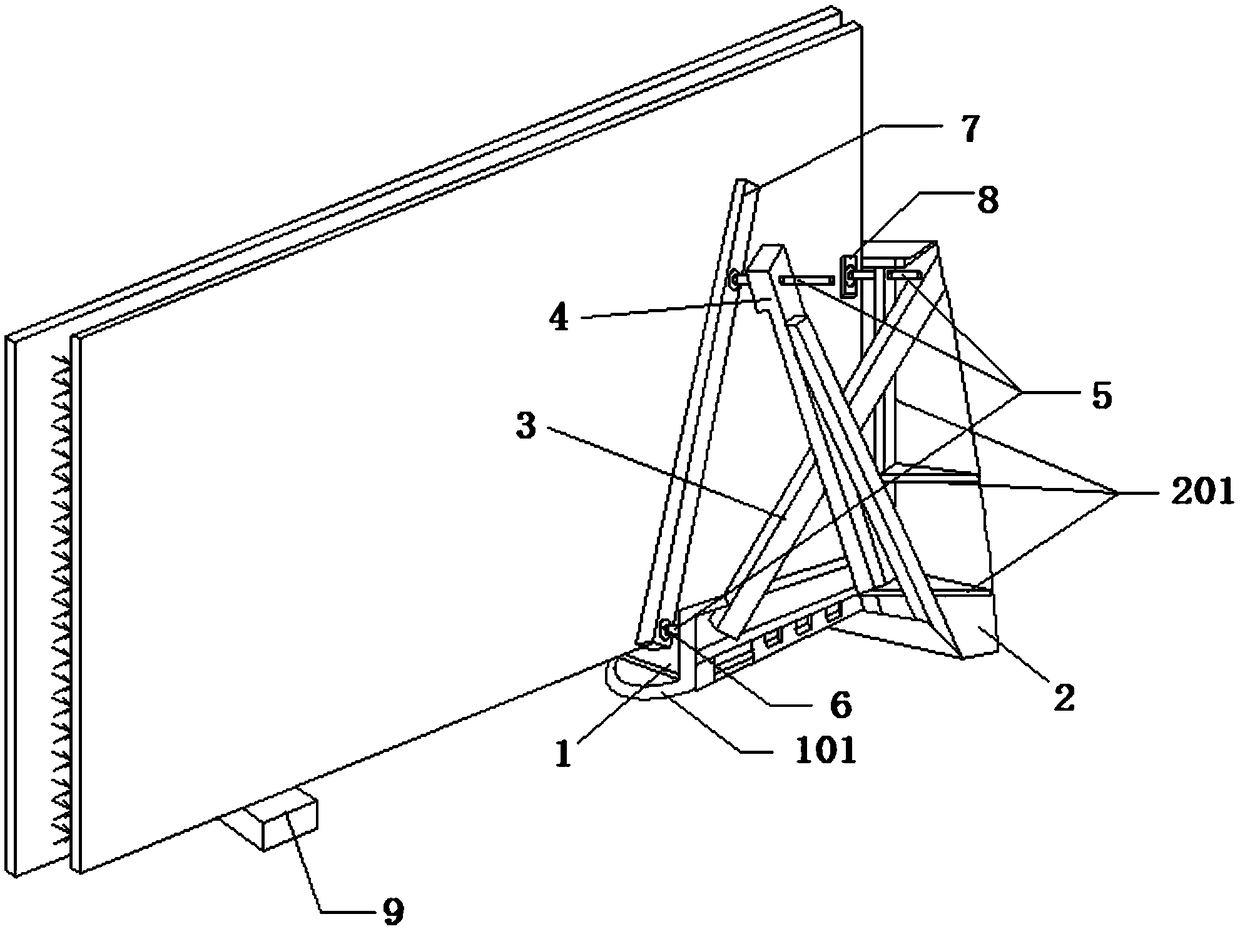

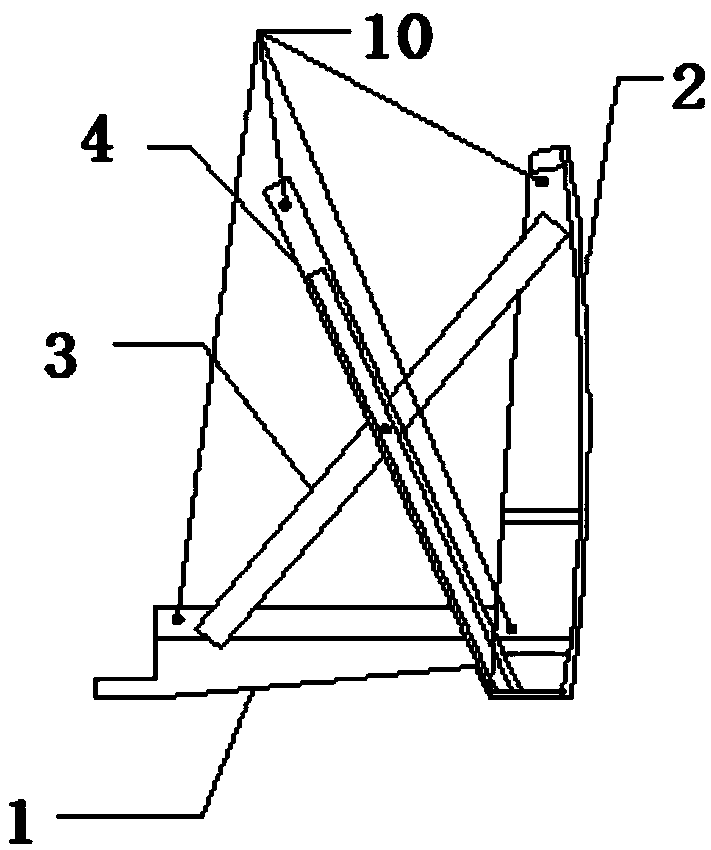

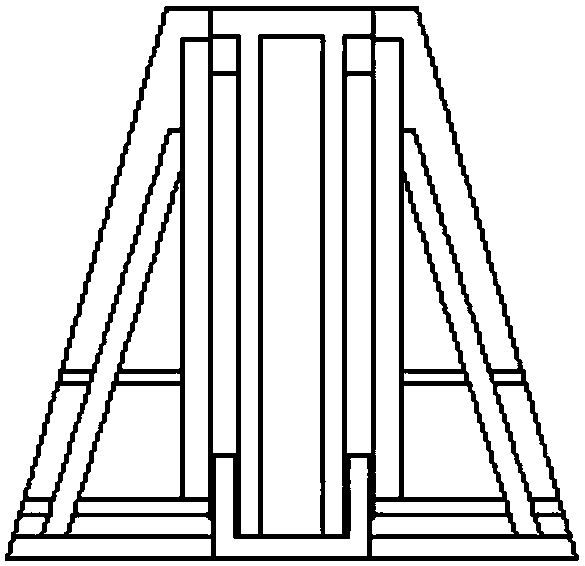

[0035] see Figure 1-Figure 8 , a turning device for vertically stacking prefabricated concrete wall panels, comprising a horizontal base 1, a steel baffle 2, both of which have a certain angle, and are fixedly connected by a triangular support frame 3; reinforced steel arms 4 and a triangular support frame 3 Set crosswise, and the two are fixedly connected by bolts; the lower end of the reinforced steel arm 4 is fixedly connected with the bottom of the steel baffle 2; the steel baffle 2 and the horizontal base 1 of the reinforced steel arm 4 are respectively provided with a 1. The fixed bolts 5 that are to be pressed inwardly to be turned over prefabricated concrete wall panels, and the degree of compression can be adjusted; Impact action of steel baffle 2.

[0036] In this example, see Figure 1-4 , the inner end of the pressing bolt is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com