Metal plate winding device

A technology of winding device and metal plate, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of untimely winding, metal plate pile up, damage to the winding device, etc., and achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

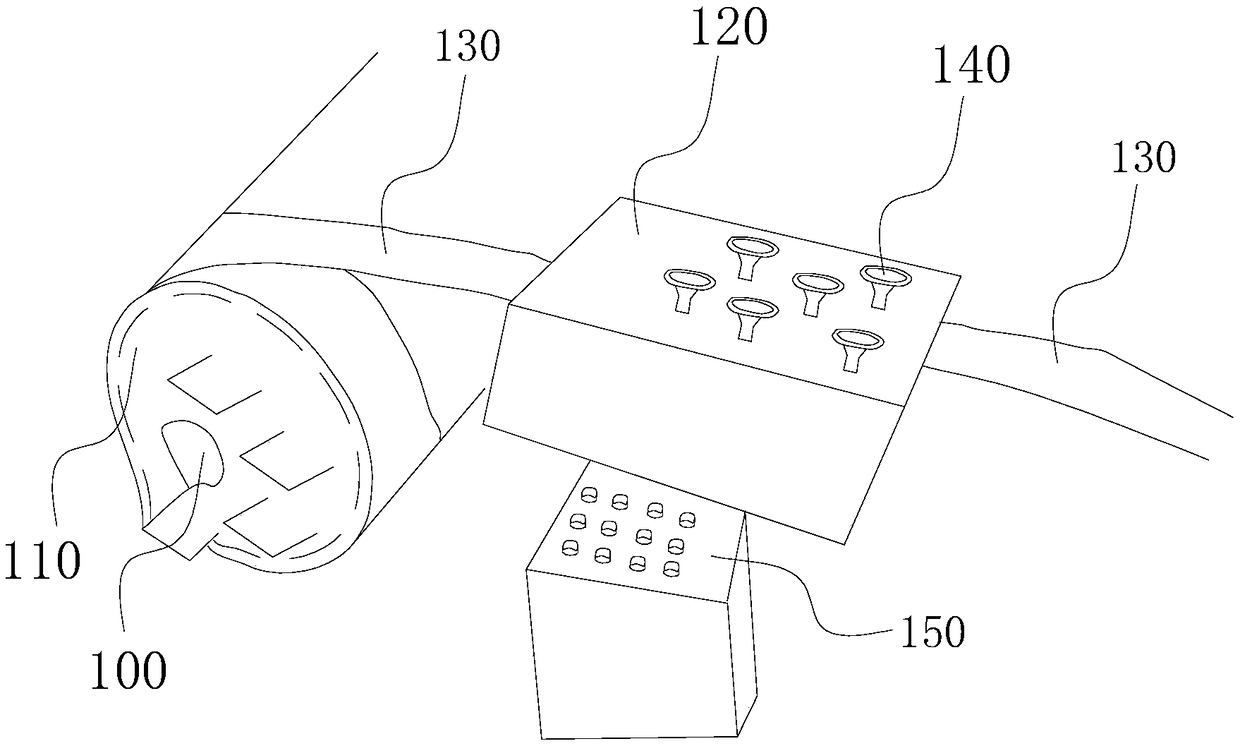

[0014] The metal plate 130 is needed to produce the steel structure, and the formed metal plate 130 usually needs to be wound to facilitate transportation and storage. When the current winding device for metal plate 130 is wound, it often occurs that the winding is not timely, which will cause the metal plate 130 to pile up, and even damage the winding device itself in serious cases. Devices, such as guide rails, rollers, etc., are sent to the front side of the winding device, and finally the winding device is wound. It can be seen that if the speed is too fast on the front side, the following winding device may not be able to respond to the winding, and the above problems will also occur. , in the same way, if the speed is too slow on the front side, the winding device may waste winding time and resources, such as electricity, labor costs, etc., which is not worth the candle.

[0015] Based on this, refer to figure 1 , the embodiment of the present invention provides a metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com