Method and winding machine for operating a winding unit

A technology for operating rolls and winding machines, which is applied in the directions of transportation and packaging, thin material handling, and delivery of filamentous materials, etc. It can solve the problems of unwinding remaining bobbins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

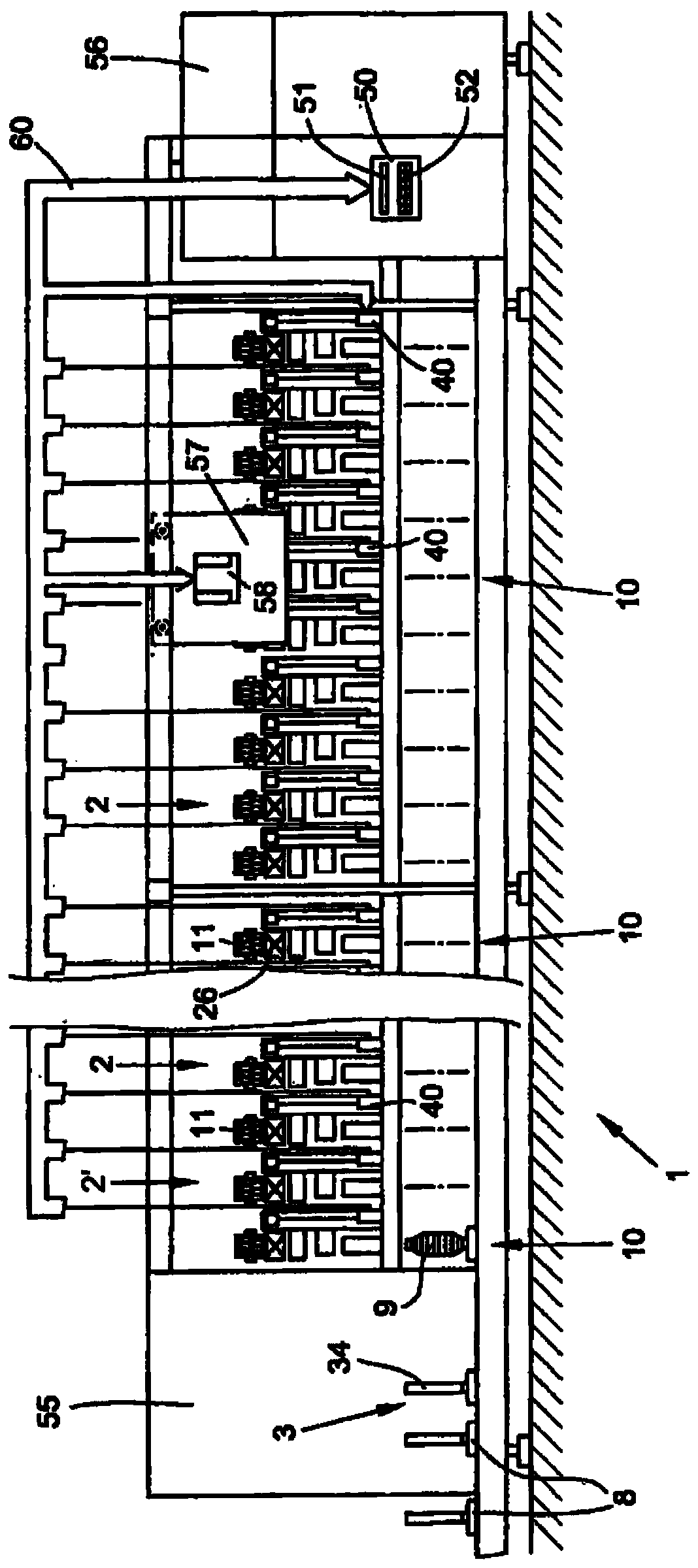

[0017] figure 1 A winding machine 1 is shown having a plurality of winding units 2 and a reference winding unit 2' arranged between end frames 55, 56 of the winding machine 1. The winding machine has a central control unit 50 connected via a bus system 60 to a winding unit controller 40 . The central control unit has a keyboard 52 and a display 51 for operation and display.

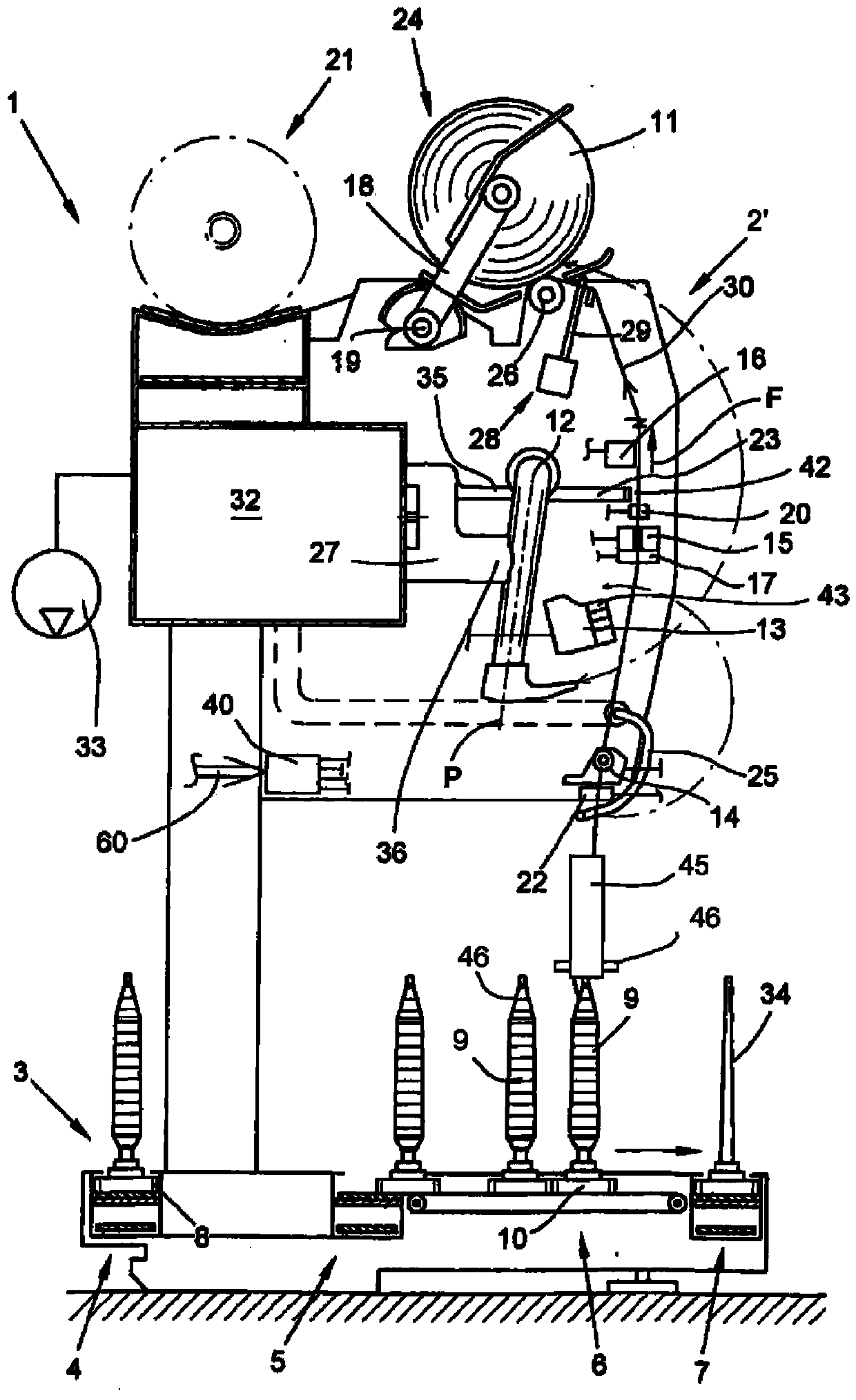

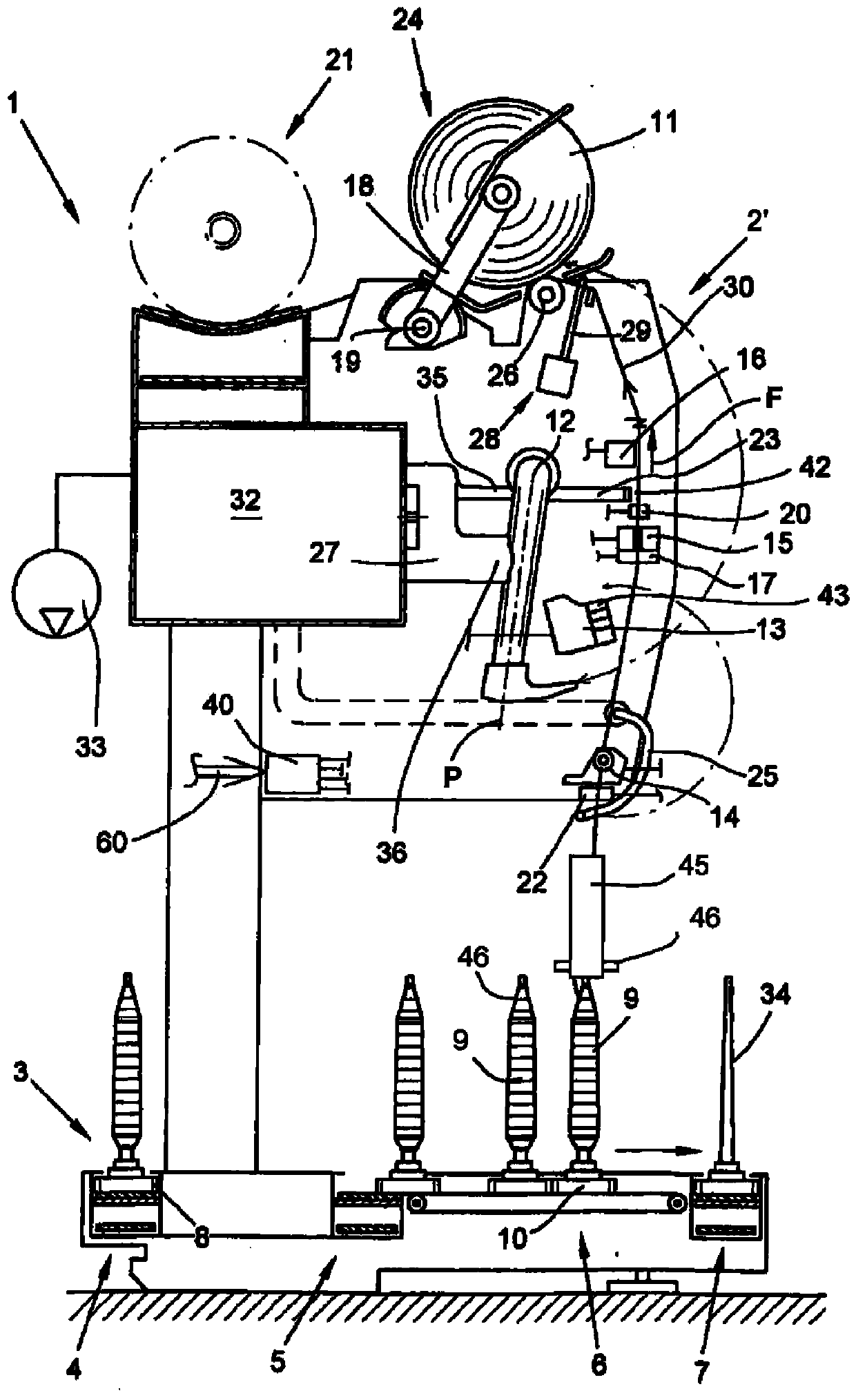

[0018] figure 2 A schematic side view of the reference winding unit 2' during the winding process is shown. The structures of the winding units 2 are all the same. Only the reference winding unit 2' additionally has a yarn tension sensor 20. At the winding unit 2, the relatively small feed package (commonly called spinning package) 9 produced on the ring spinning machine with only relatively little yarn material is rewound into a bulky cross-wound package 11, due to This is well known and therefore will not be described in more detail. The finished cross-wound bobbins 11 are then transferred b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com