Movable arm type tower crane supporting system auxiliary circulating lifting transport device and construction method thereof

A technology of support system and auxiliary circulation, applied in the direction of cranes, etc., can solve problems such as unfavorable overall vertical lifting of the lower support system, damage to the lifting space of the main frame and support rods, and influence on site construction operations, so as to avoid the lifting space. Insufficient, avoid hoisting impact, save space and man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

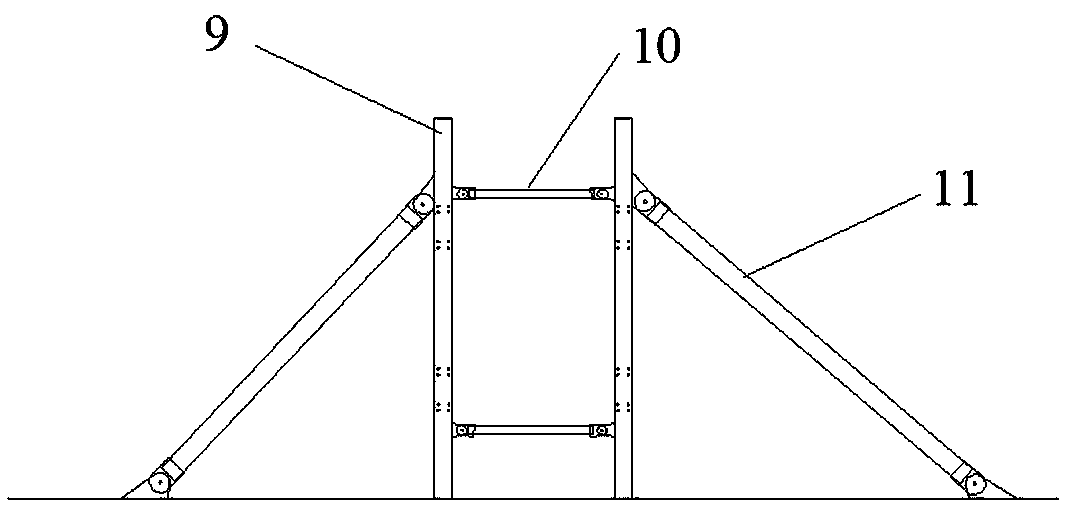

[0033] This embodiment adopts the design of 3 sets of support frames and 3 sets of C-shaped frame bases 19 for each tower crane. As the tower crane climbs and turns over, the 2 support frames work together during normal operation of the tower crane. According to the shortest construction interval of the structure and the requirements of climbing formwork climbing planning, the climbing height and times of the jib tower are finally determined.

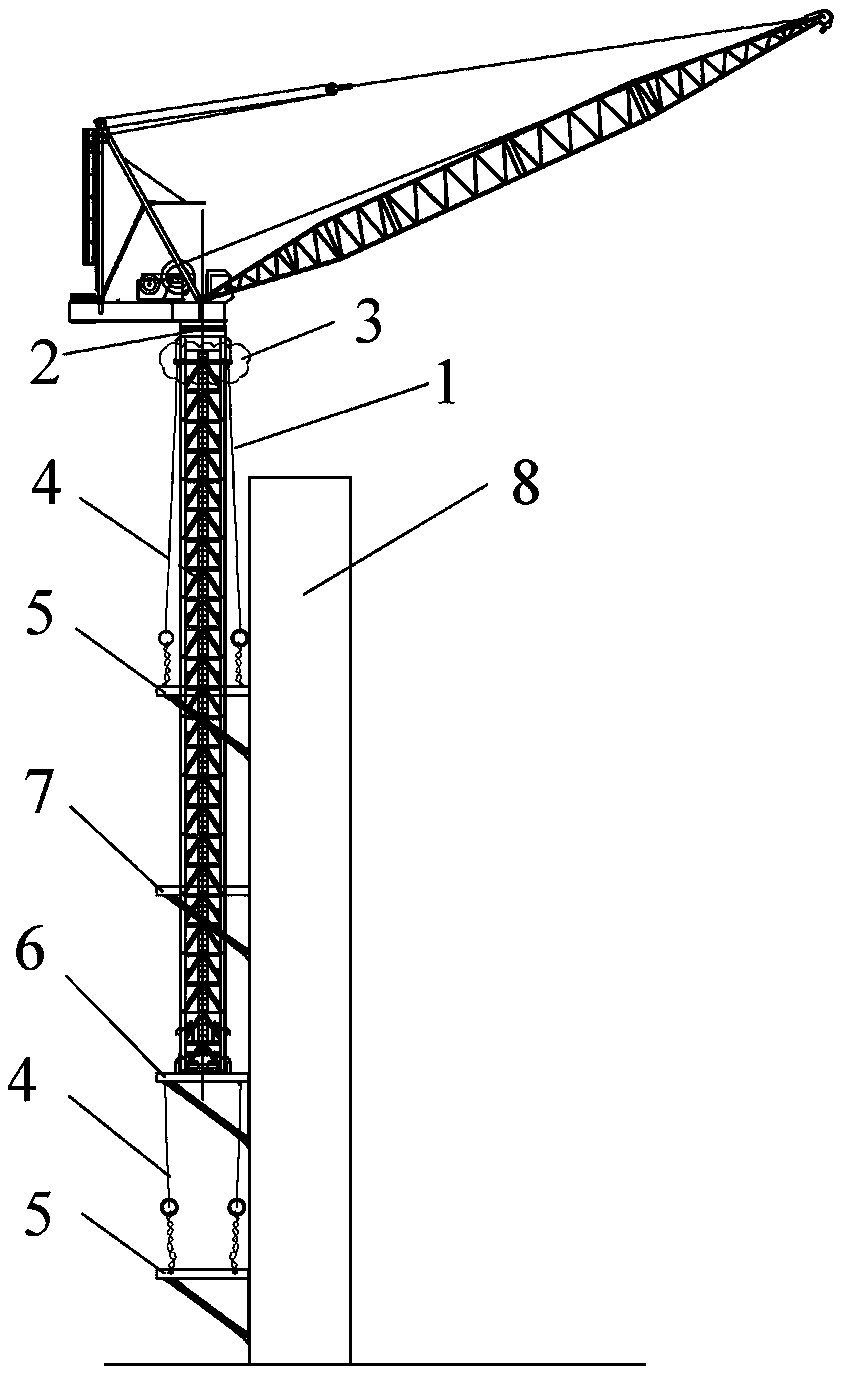

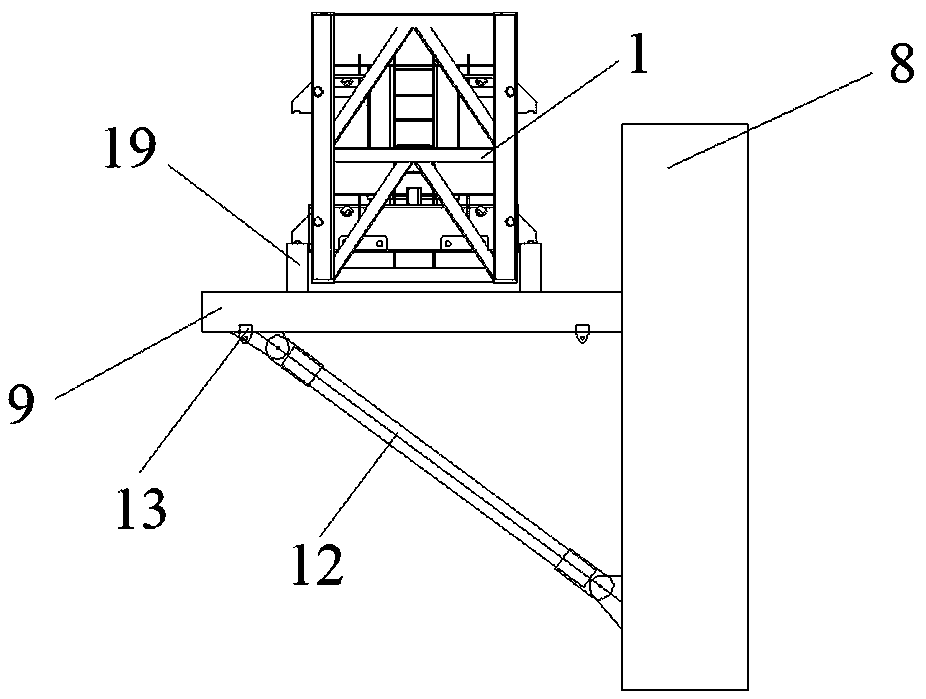

[0034] like figure 1 As shown, a boom-type tower crane support system auxiliary circulation reversing device includes a boom-type tower crane. The standard section 1 also includes a set of supports 3, which are connected to both sides of the top of the standard section 1 and correspondingly connected to the base of the turntable 2; the bottom surface of the supports 3 is vertically connected with lifting lugs 13, the lifting lugs 13 is connected with a suspension chain 4, and the lower end of the suspension chain 4 is connected with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com