Buckling restrained brace

A technology of anti-buckling energy dissipation and yield limit, applied in seismic, building components, building types, etc., can solve problems such as poor low-cycle fatigue performance and fatigue fracture, and achieve improved seismic performance, strong cumulative plastic deformation capacity and hysteresis. The effect of energy dissipation capacity, excellent room temperature low cycle fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

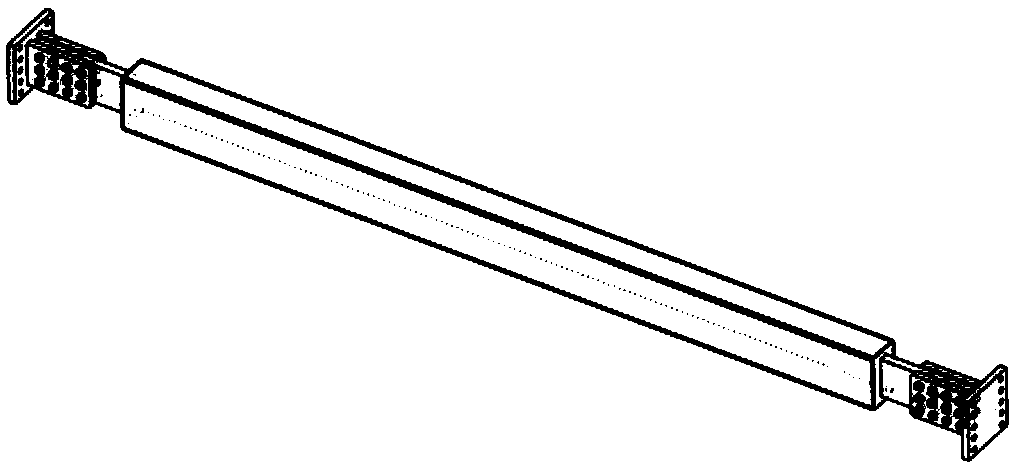

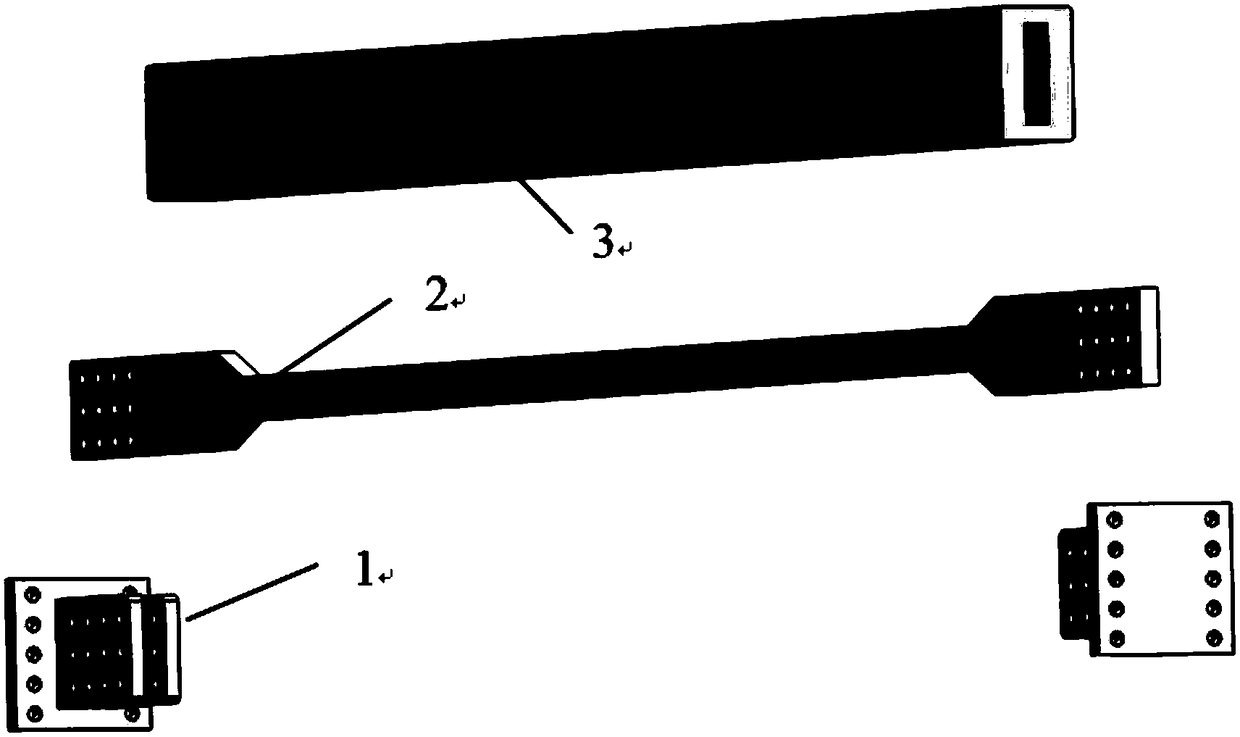

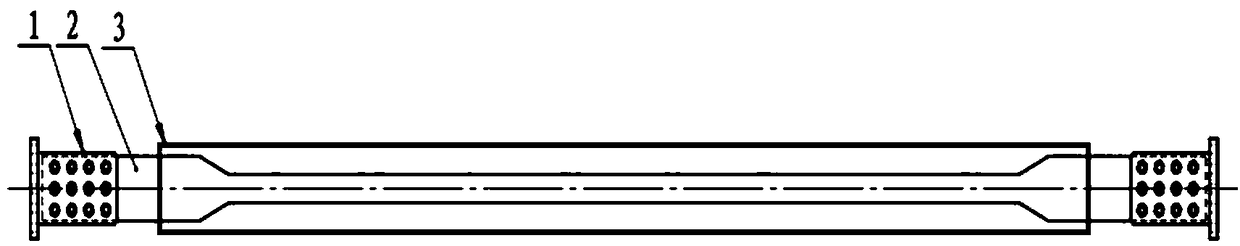

[0034] Such as figure 1 , figure 2 and image 3 As shown, a new type of bolt-connected anti-buckling energy-dissipating support is composed of three parts: an end restraint section 1, a buckling section 2 and a casing 3; the end restraint section 1 is located at both ends of the buckling section 2, It plays the role of transmitting load, and one side of it is connected with the buckling section 2; the buckling section 2 undertakes plastic deformation and hysteretic energy dissipation; the casing 3 is fixed on the outside of the buckling section 2 by grouting and filling concrete, And there is a layer of unbonded material between the concrete and the outside of the buckling section.

[0035]The cross-sectional shape of the buckling section 2 is straight, the cross-section is narrow in the middle and wide at both ends along the axial direction, and the ratio of the cross-sectional area of the middle part to the two ends is 2:1. The material of the buckling section 2 is all...

Embodiment 2

[0040] refer to Figure 4 , Figure 5 and Figure 6 , a welded joint type anti-buckling energy-dissipating support, which is composed of three parts: an end restraint section 1, a buckling section 2 and a casing 3; the end restraint section 1 is located at both ends of the buckling section 2, and one side thereof Connected to the buckling section 2; the buckling section 2 undertakes plastic deformation and hysteretic energy dissipation; the casing 3 is fixed on the outside of the buckling section 2 by grouting and filling concrete, and there is a gap between the concrete and the outside of the buckling section layer without adhesive material. In this embodiment, the casing is square.

[0041] The cross-sectional shape of the buckling section 2 is cross-shaped, and the cross-shaped cross-section is narrow in the middle and wide at both ends along the axis direction, and the ratio of the cross-sectional area of the middle part to the two ends is 2:1. The cross section is o...

Embodiment 3

[0046] refer to Figure 7 and Figure 8 , a threaded joint type anti-buckling energy-dissipating support, which is composed of three parts: an end restraint section 1, a buckling section 2 and a casing 3; the end restraint section 1 is located at both ends of the buckling section 2, and one side thereof Connected to the buckling section 2; the buckling section 2 undertakes plastic deformation and hysteretic energy dissipation; the casing 3 is fixed on the outside of the buckling section 2 by grouting and filling concrete, and there is a gap between the concrete and the outside of the buckling section layer without adhesive material. In this embodiment, the sleeve is in the shape of a circular tube.

[0047] The cross-sectional shape of the buckling section 2 is circular, and the circular cross-section is narrow in the middle and wide at both ends along the axial direction, and the ratio of the cross-sectional area of the middle part to the two ends is 2.5:1. The material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com