Self-resetting pressure bearing and shock reducing water stop part and tunnel flexible connector

A flexible joint and self-resetting technology, applied in tunnels, tunnel linings, shaft equipment, etc., can solve problems such as large permanent deformation, difficult repairs, complex structures, etc., and achieve the effects of reducing damage and improving earthquake safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

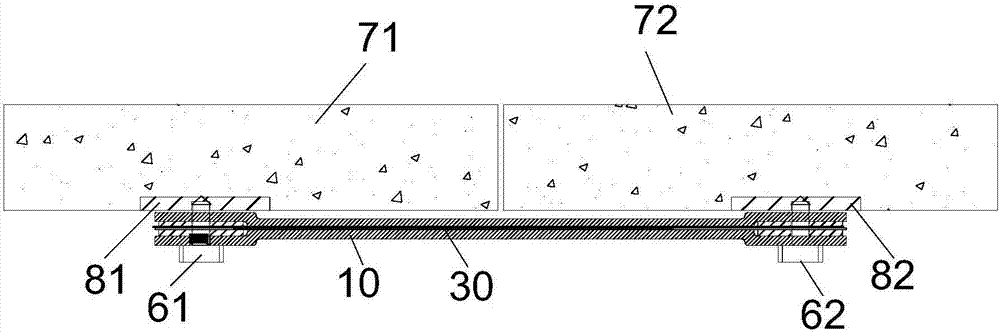

[0033] Embodiment 1 discloses a self-resetting, pressure-bearing, shock-absorbing, and water-stopping member, which is used to connect tunnel segments of flexible joints in tunnels. For example, traditional tunnel segments (such as figure 2 The original longitudinal connecting bolts on the first tunnel segment 71 and the second tunnel segment 72) are canceled or partially canceled, and the self-resetting pressure-bearing shock-absorbing water-stop is installed to achieve the purpose of improving the flexible joint of the tunnel.

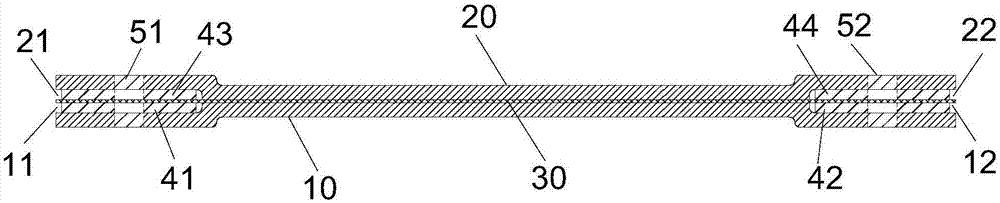

[0034] see Figure 1 to Figure 3 , the self-resetting pressure-absorbing, shock-absorbing and water-stopping member includes: a first water-stopping rubber layer 10 and a second water-stopping rubber layer 20 arranged oppositely, arranged between the first water-stopping rubber layer 10 and the second water-stopping rubber layer 20, the shape memory alloy plate 30, the first thickened clamping steel plate 41, the second thickened clamping steel pla...

Embodiment 2

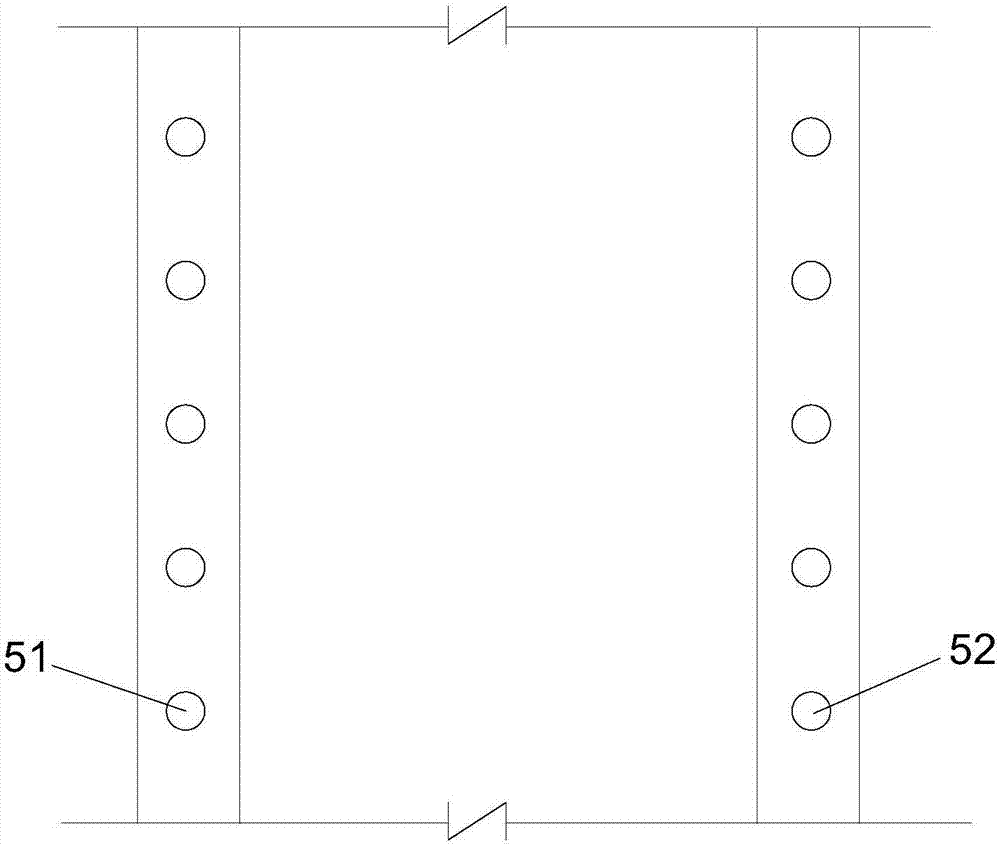

[0043] see also Figure 1 to Figure 3 , a tunnel flexible joint disclosed in Embodiment 2, including a first tunnel segment 71, a second tunnel segment 72, a first high-strength bolt 61, a second high-strength bolt 62, and any one of the self-resetting bearings in Embodiment 1 Pressure-reducing, shock-absorbing and water-stopping parts. The first high-strength bolt 61 fixedly connects and compresses the self-resetting pressure-bearing, shock-absorbing, water-stopping member to the inner side of the first tunnel segment 71 through the first bolt hole 51, and the second high-strength bolt 62 connects the self-resetting bearing through the second bolt hole 52. The pressure-absorbing, shock-absorbing and water-stopping member is fixedly connected to and pressed against the inner side of the second tunnel segment 72 .

[0044] In a further preferred solution, the tensile stiffness of the shape memory alloy plate 30 is smaller than the stiffness of the longitudinal bolts of common ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com