Electric heating cooperative optimization operation method

A technology of collaborative optimization and operation method, applied in heating methods, household heating, space heating and ventilation details, etc., can solve problems such as large power loss, low load temperature utility, and load spikes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

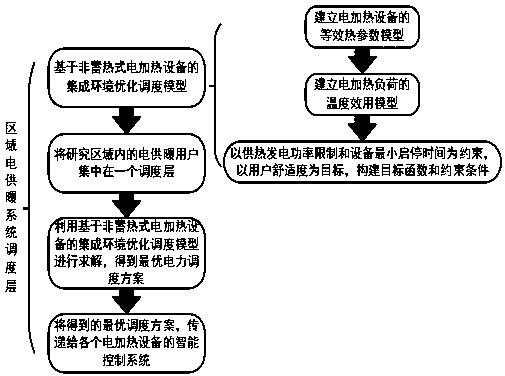

[0042] The present invention will be further explained below in conjunction with the drawings:

[0043] Such as figure 1 As shown, the collaborative optimization operation method of electric heating includes the following steps:

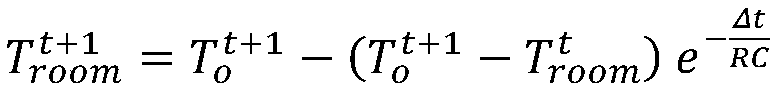

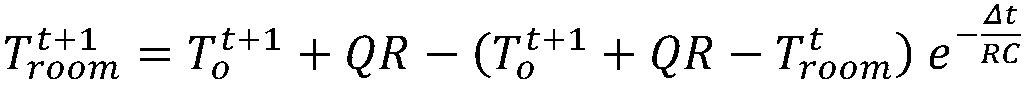

[0044] (1) According to the operating characteristics of the electric heating equipment, establish the equivalent thermal parameter model of the electric heating equipment.

[0045] (2) According to the actual temperature benefit produced by the output of the electric heating equipment under the change of the external temperature, the temperature utility model of the electric heating load is established.

[0046] (3) Taking the maximum power limit of the electric heating and power generation of the power system and the minimum start-stop time of the electric heating equipment as the constraints, and the optimal user heating comfort as the goal, construct the objective function and constraint conditions, and combine the steps (1 ) (2) The constructed models...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com