Cold firework spark spraying machine

A firework and spraying technology, which is applied in the field of cold flame spraying machines, can solve the problems of deviation from the center of the spraying tube, affecting the spraying effect, and the center of the spraying is not correct, and achieves the effects of increased structure, simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

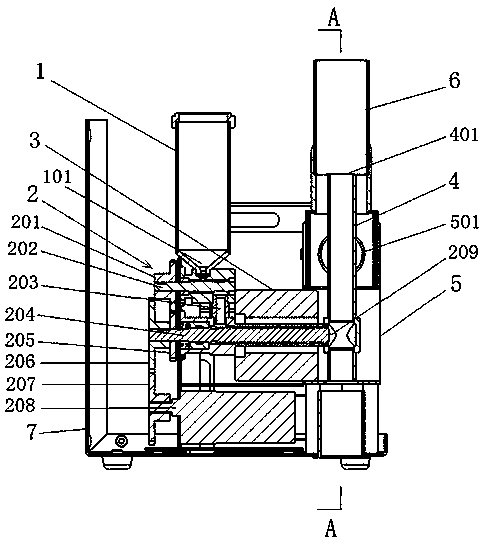

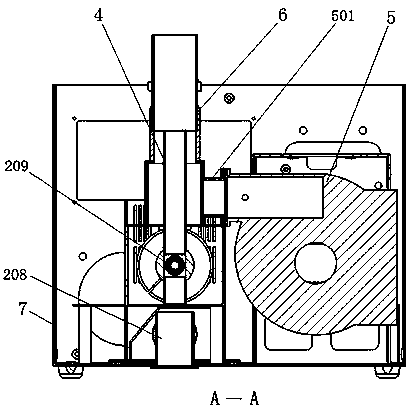

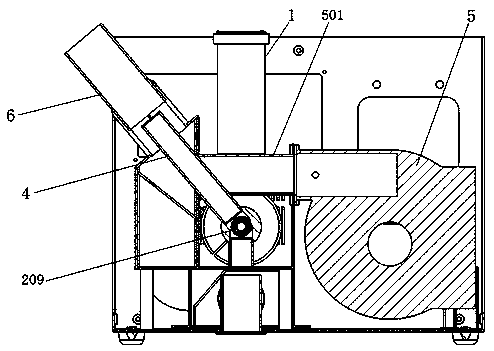

[0015] Such as figure 1 , figure 2 As shown, the cold fireworks spray machine provided by the present invention includes a storage device 1 installed on a frame 7, a feeding device 2, an electric heating device 3, an air supply device 5, a material suction pipe 4, and a spray pipe 6; The electric heating device 3 is arranged on the feeding device 2, the material storage device 1 communicates with the feeding port of the feeding device 2, and the suction pipe 4 is sleeved on the central axis of the flower spray pipe 6, and the material is sucked. The lower part of the pipe 4 communicates with the discharge port 209 of the feeding device 2, and the flower spray pipe 6 communicates with the air supply device 5. The position behind the feed opening 401; the bottom of the flower spray pipe 6 is closed, the suction pipe 4 extends into the flower spray pipe 6 from the bottom of the spray pipe 6, and the air supply device 5 adopts a fan, and its air supply port 501 is set On the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com