An ice thickness monitoring device and method based on the principle of water body liquid-solid phase change volume change

A monitoring device and variable volume technology, applied in mechanical thickness measurement and other directions, can solve problems such as low efficiency, large error, and observation cost constraints, and achieve simple and convenient installation and disassembly operations, avoiding waste of manpower and resources, and stable and reliable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

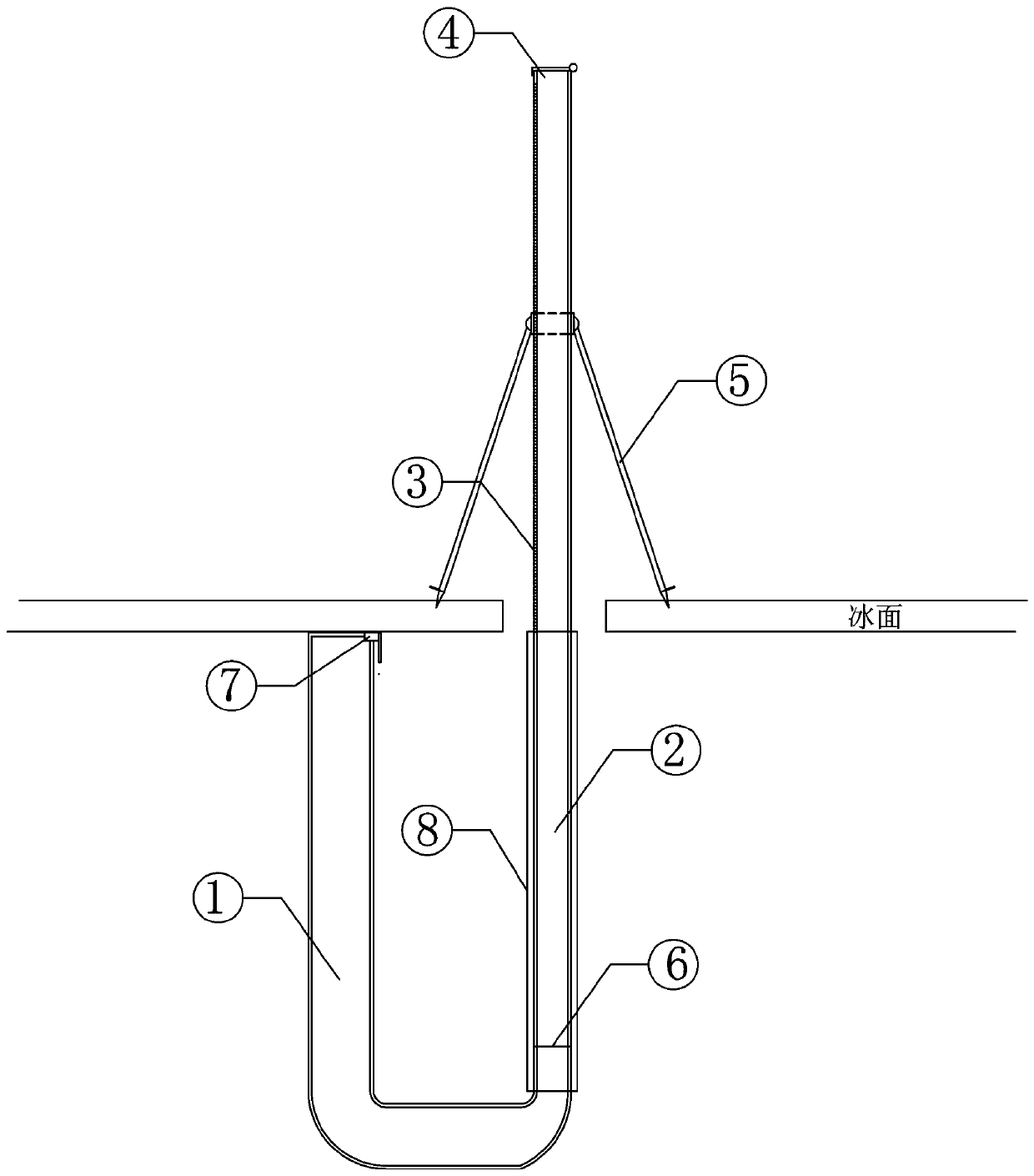

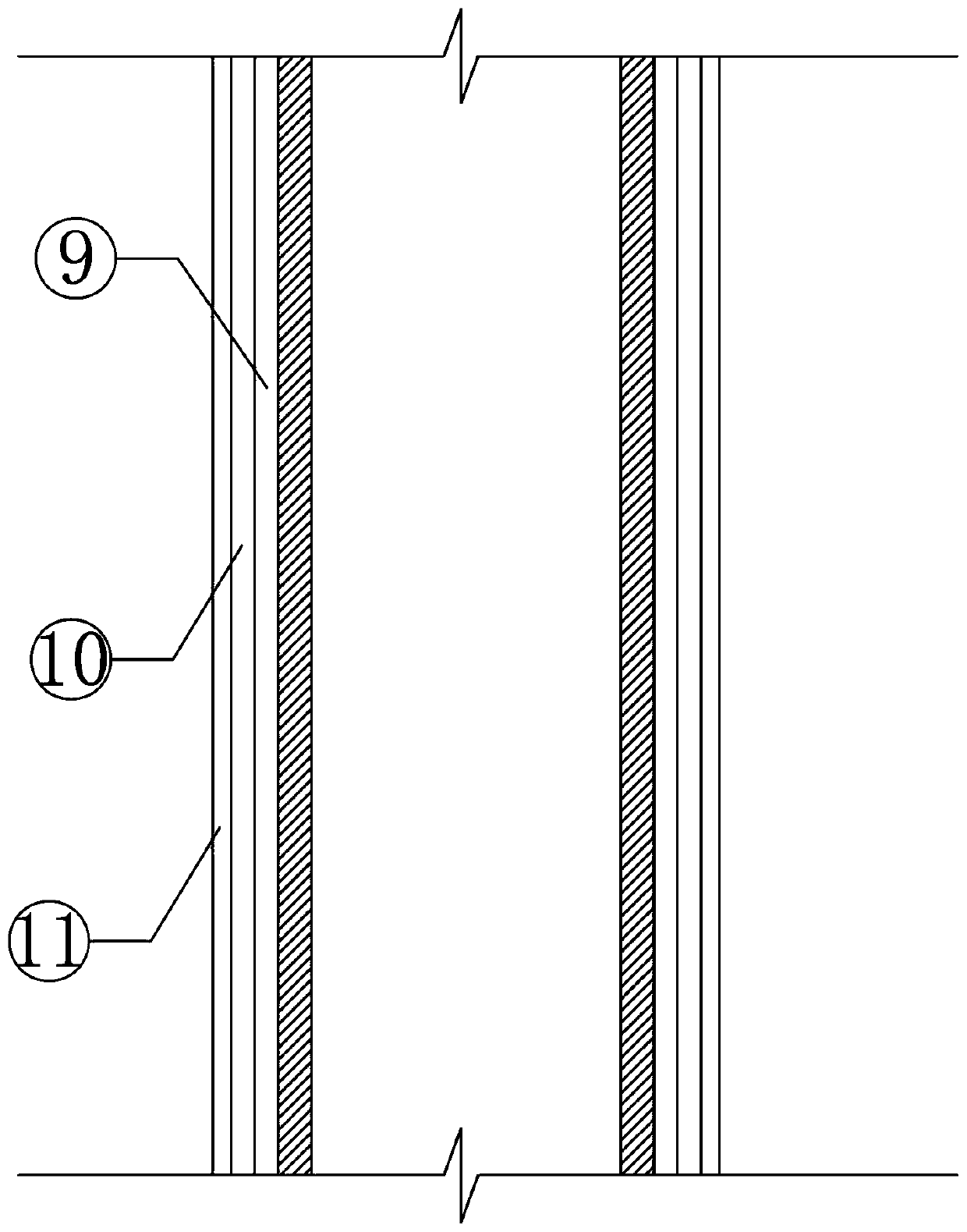

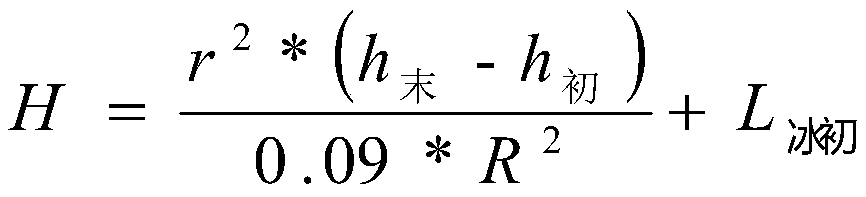

[0018] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. An ice thickness monitoring device based on the principle of water body liquid-solid phase change volume change is fixed by a plexiglass tube 2 and a steel pipe 1 through a waterproof threaded connection 6; A foldable tripod 5 is installed on the tube 2, and a scale 3 is engraved on the plexiglass tube 2; the zero scale of the scale 3 is flush with the outer surface of the steel pipe 1 end; The top cover 4; the end of the steel pipe 1 is fixed with a ball valve 7, the radius of the steel pipe 1 is greater than the radius of the plexiglass pipe 2, and the steel pipe 1 and the plexiglass pipe 2 need to be injected with oil and water at the measurement site. The protective sleeve 8 is composed of a deformable layer 11, an anti-floating layer 10 and an insulating layer 9; the deformable layer 11 does not lose its elasticity in an extremely cold environment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com