Scanning self-check system after UV coding

A technology of self-inspection system and scanning head, which is applied in the field of commodity coding, can solve the problems of low efficiency, time-consuming and labor-intensive, etc., and achieve the effect of ensuring quality, complete and accurate coding, and avoiding shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

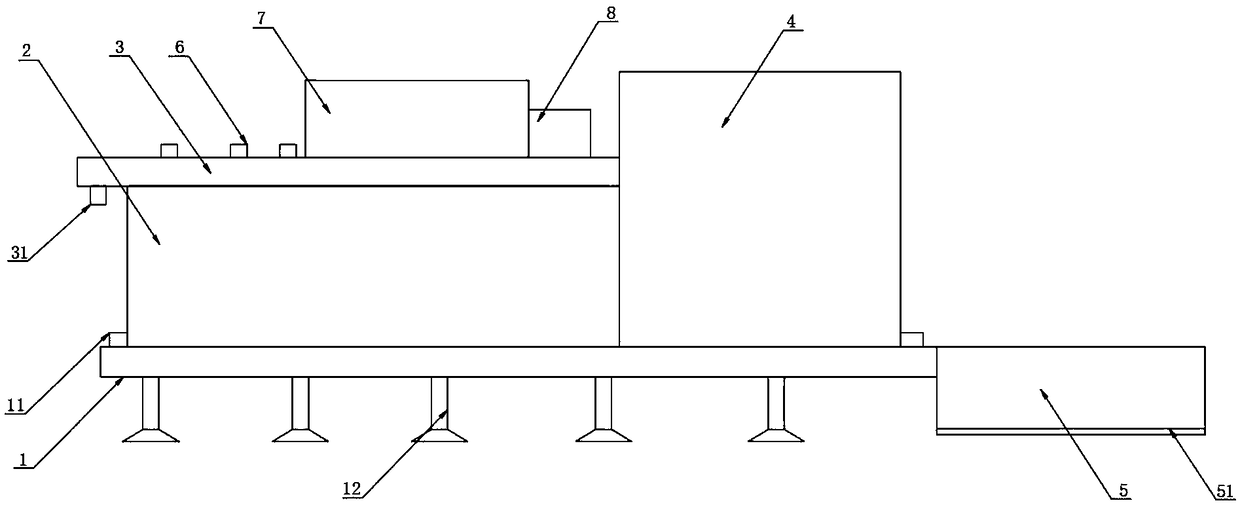

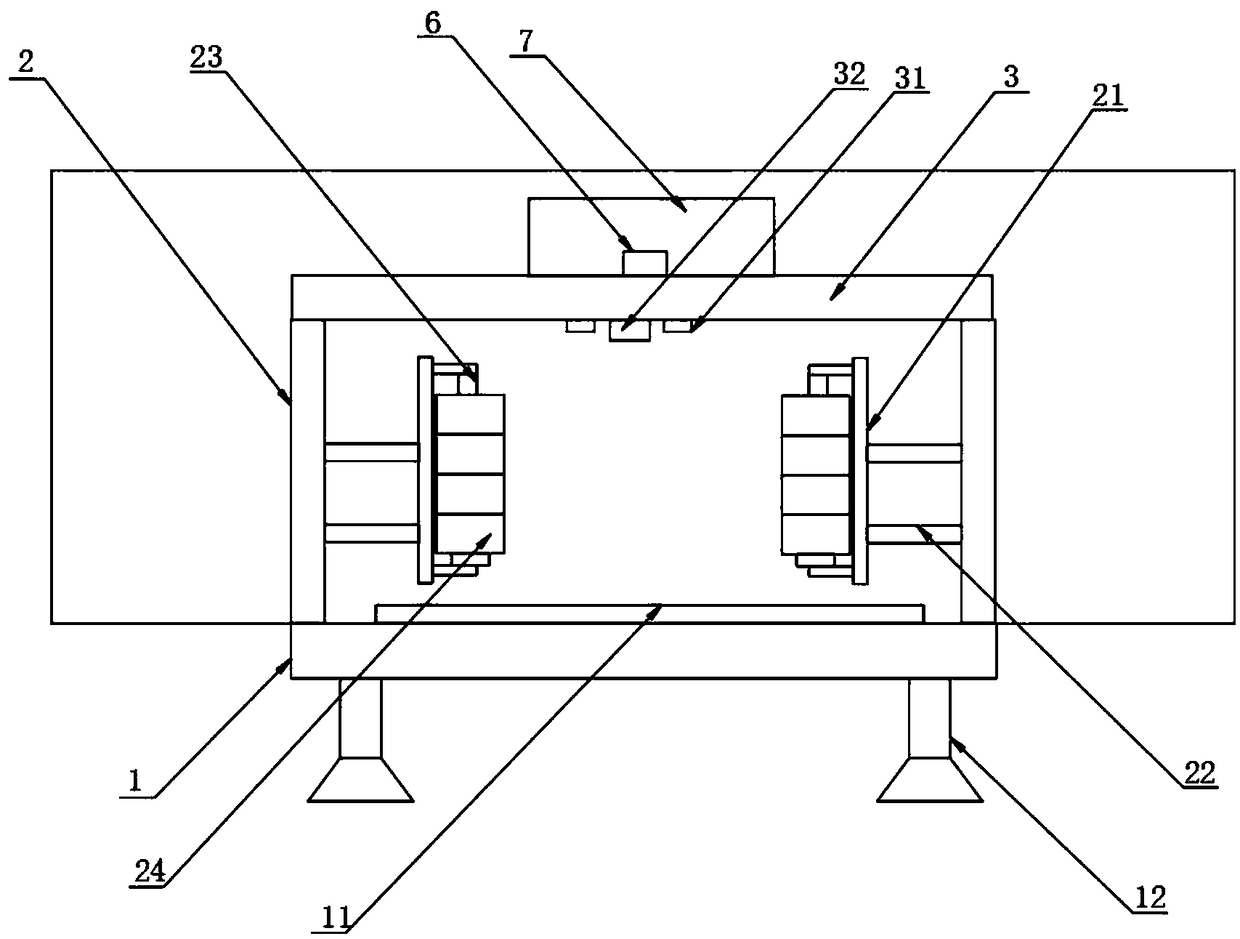

[0024] The present invention provides such as Figure 1-4 A scanning self-inspection system after UV coding is shown, including a base 1, a side plate 2 is provided on the top of the base 1, a top plate 3 is provided on the top of the side plate 2, and a scanning plate is provided on one side of the side plate 2. Device 4, the scanning device 4 includes a scanning housing 41, a first transmission plate 42, a second transmission plate 43, a push plate 44, a second electric push rod 45, a tilting block 46, a top scanning head 47, a mounting plate 48 and Side scanning head 49, described base 1 side is provided with storage case 5, and described top plate 3 top is provided with buzzer 6, and described buzzer 6 side is provided with control device 7, and described control device 7 One side is provided with display screen 8.

[0025] The top surface of the base 1 is provided with a transmission panel 11 , the transmission panel 11 is arranged between two side plates 2 , and the bot...

Embodiment 2

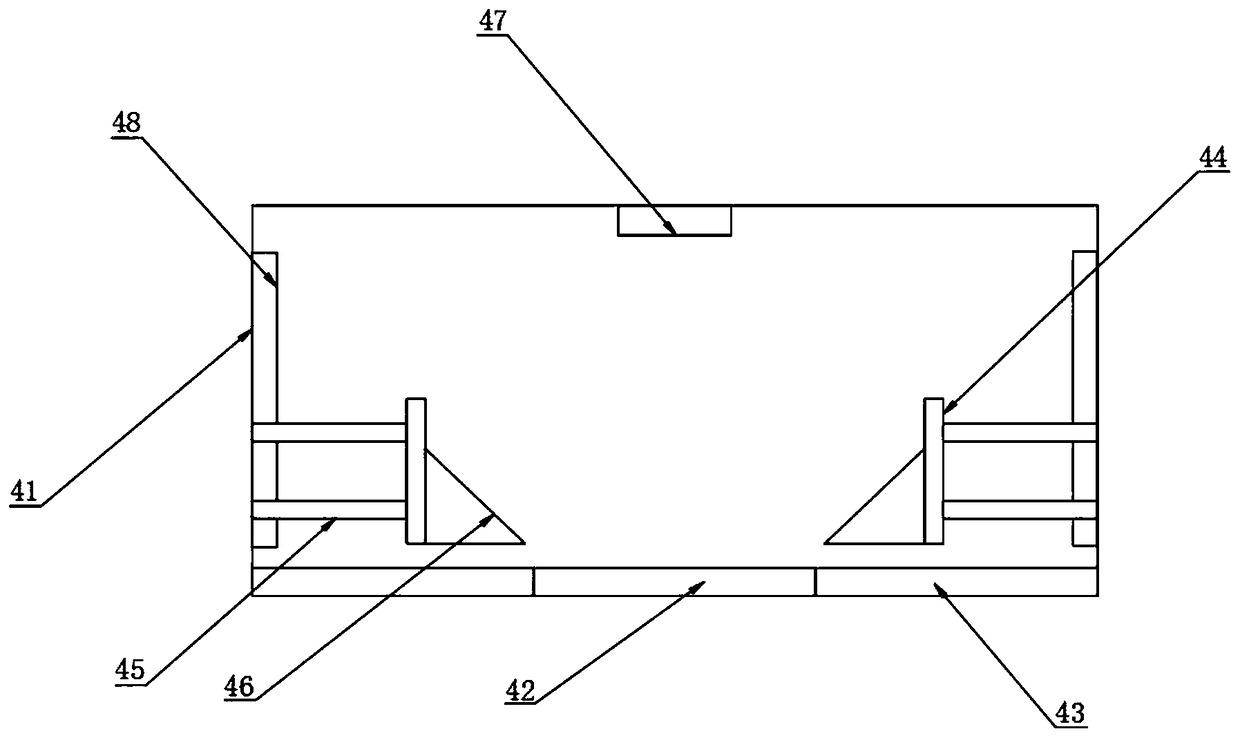

[0030] The scanning housing 41 is hollow and arranged on the top of the base 1, the bottom of the inner wall of the scanning housing 41 is provided with a first transmission plate 42, and the two sides of the first transmission plate 42 are provided with a second transmission plate 43, Push plates 44 are arranged on both sides of the inner wall of the scanning housing 41, a second electric push rod 45 is arranged between the pushing plate 44 and the inner wall of the scanning housing 41, and an inclined block 46 is arranged on the inner side of the pushing plate 44. The top of the inner wall of the scanning housing 41 is provided with a top scanning head 47, and the outer side of the second electric push rod 45 is provided with a mounting plate 48, and the mounting plate 48 is arranged on both sides of the inner wall of the scanning housing 41. The mounting plate 48 A side scanning head 49 is evenly arranged inside, and a label scanner is arranged inside the top scanning head 4...

Embodiment 3

[0034] The number of the storage housings 5 is set in multiples and are respectively arranged outside the first transmission plate 42 and the second transmission plate 43 , and a weighing device 51 is provided at the bottom of the storage housings 5 .

[0035] Described buzzer 6 quantity is set to a plurality of, and described buzzer 6 and display screen 8 all communicate with control device 7 through transmission cable, and described control device 7 is internally provided with data receiving module, data processing module, PLC. A controller, a wireless data transmission module and a data storage module. The outside of the control device 7 is connected to a server through an Ethernet transmission cable. The server is connected to the manufacturer's internal information network and can extract the range of predetermined coding numbers for different commodities.

[0036] Beneficial effects of this embodiment: the storage housing 5 is three stores for commodities that meet the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com