Automatic-pressure-control liquid control container

A container and pressure technology, applied in the field of containers, can solve the problems of insufficient sanitation and environmental protection, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

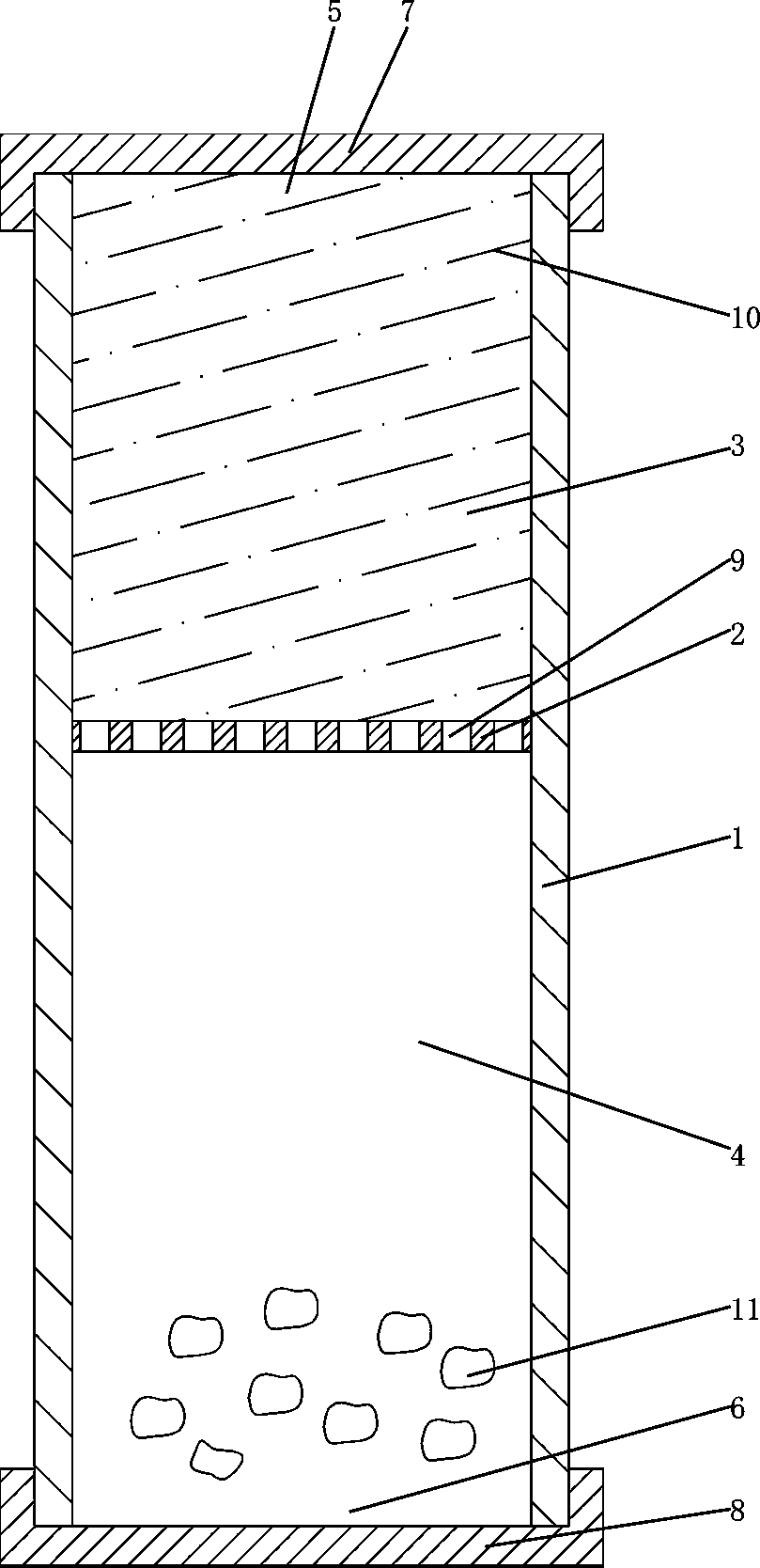

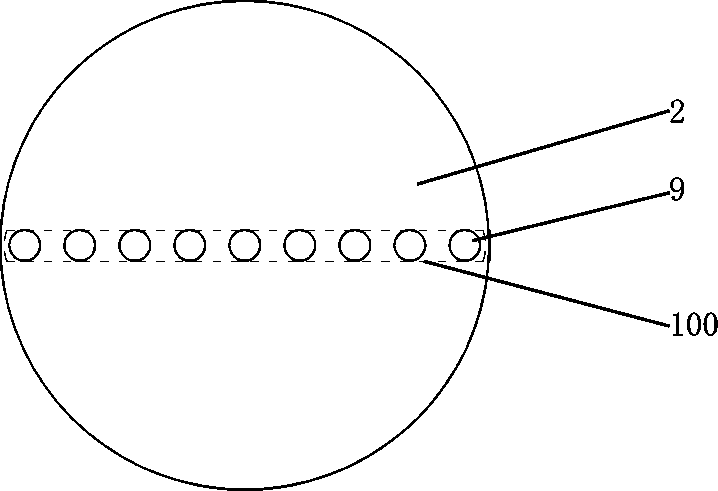

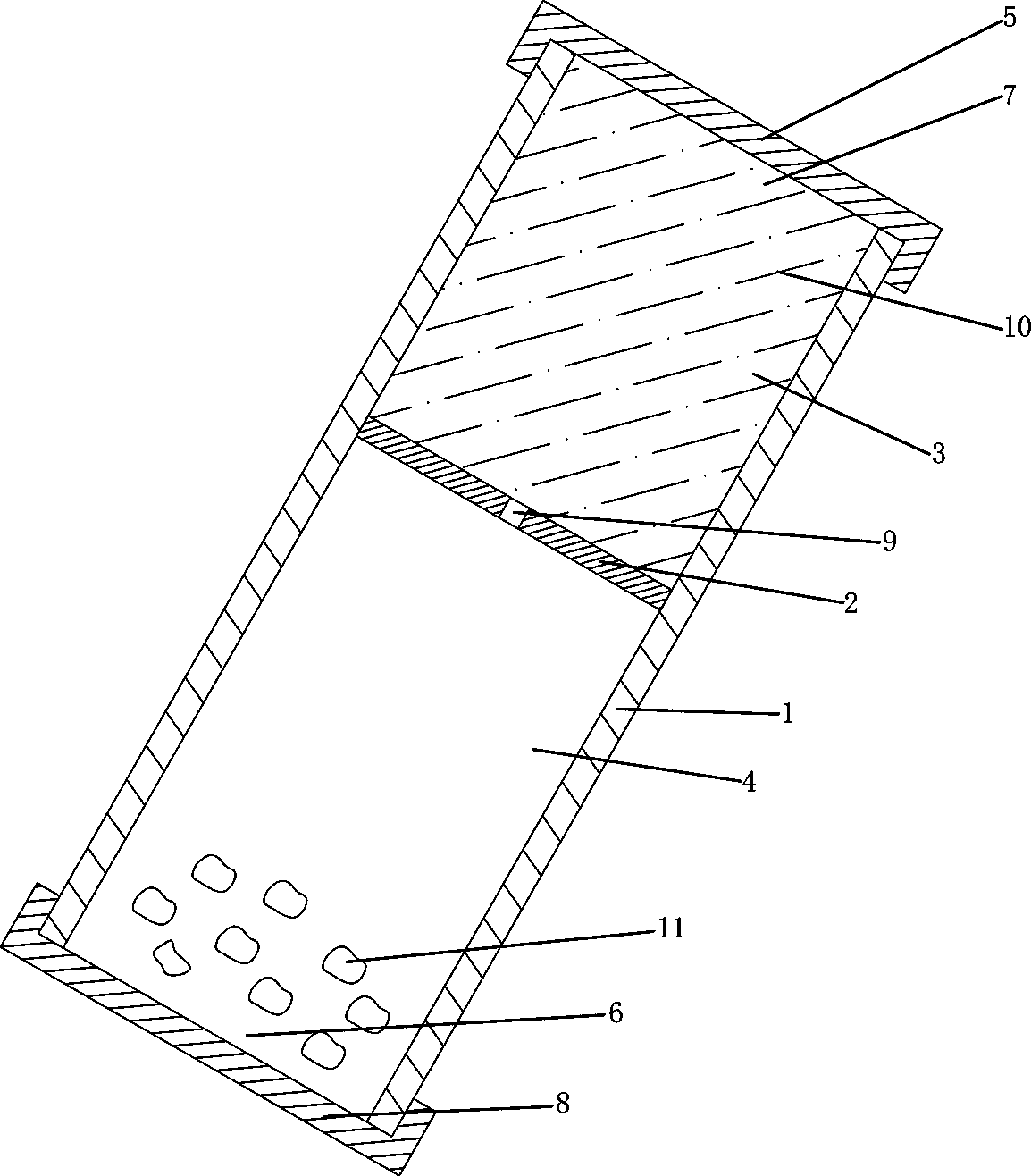

[0030] Such as figure 1 , figure 2 As shown, this pressure self-control liquid control container includes a transparent container 1 and a partition 2, and the partition 2 is arranged in the inner cavity of the transparent container 1 and divides the inner cavity of the transparent container 1 into a first cavity 3 and a second cavity. Two chambers 4, the dividing plate 2 is fixed and sealed connected with the inner wall of the transparent container 1; the transparent container 1 is provided with a first port 5 and a second port 6, the first port 5 communicates with the first cavity 3, and the first port 5 A first sealing end cap 7 is provided on the top, and the second port 6 communicates with the second cavity 4, and a second sealing end cap 8 is provided on the second port 6; a strip-shaped area 100 is provided on the partition 2, and the strip-shaped area 100 is provided with seven water passage holes 9, and each water passage hole 9 is on the same straight line; Inverse...

Embodiment 2

[0043] Such as Figure 5 , Figure 6 As shown, in the case that other parts are the same as the first embodiment, the difference is that: on the strip area 100 on the separator 2, a plurality of water holes 9 are arranged in three rows. The principle of blocking liquid and passing liquid is basically the same as that of Embodiment 1, except that there is a slight difference in blocking liquid: the strip area 100 is in a horizontal state, and the liquid 10 should be completely submerged no matter whether the transparent container 1 is placed vertically, inclined, or horizontally. Only three rows of water holes 9 can block the liquid 10 , and the blocking of the liquid depends more on the surface tension of the liquid 10 .

Embodiment 3

[0045] Such as Figure 7 As shown, in the case that other parts are the same as in the second embodiment, the difference lies in that each water hole 9 is arranged in disorder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com