Manufacturing tool for rubber strip sealing ring

A technology for making tools and rubber strips, applied in the direction of manufacturing tools, workbenches, metal processing, etc., can solve the problems of low production efficiency of manual cutting rubber strips, short rubber strips, production failures, etc., to achieve high production efficiency and improve sealing effect. , to avoid a matte effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

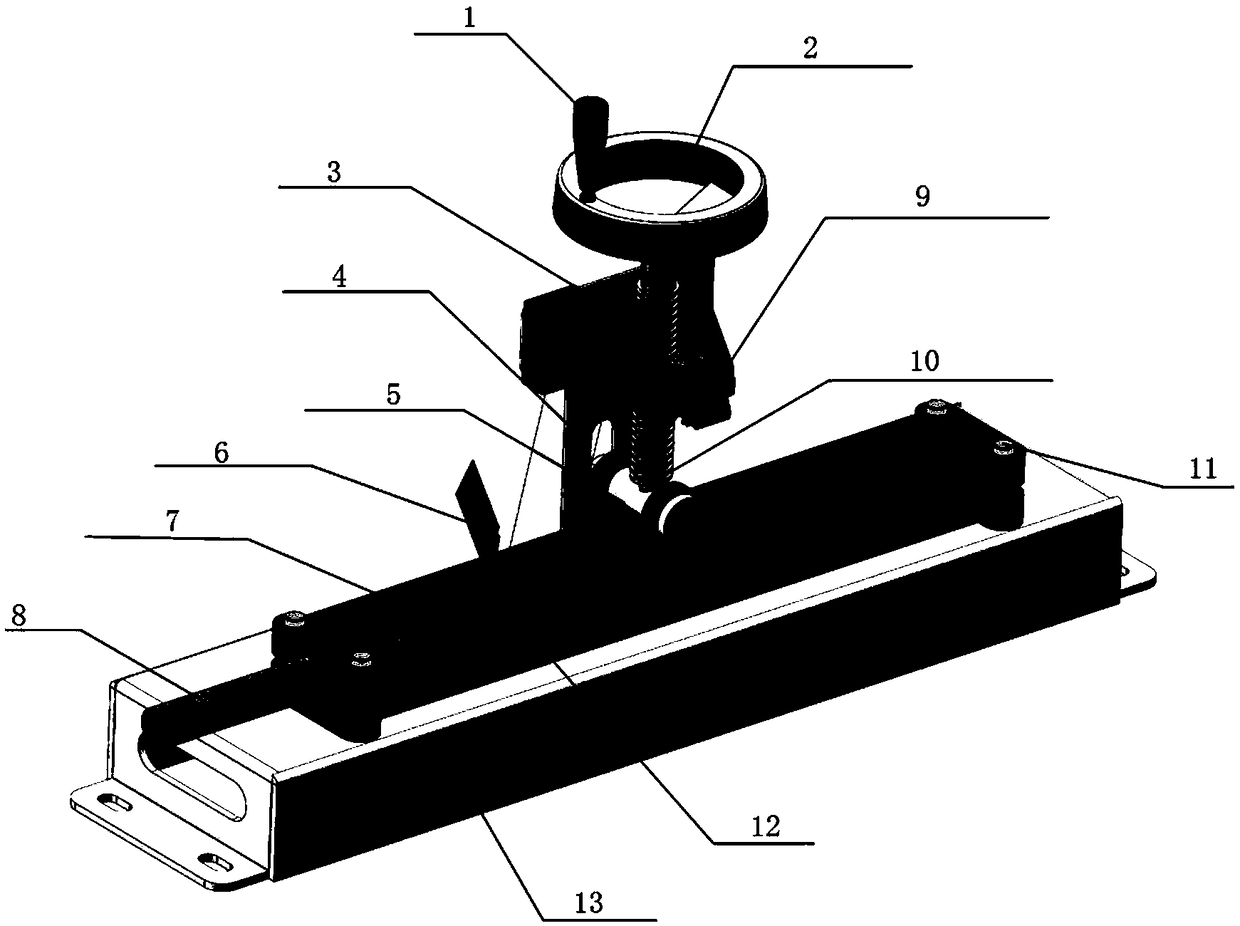

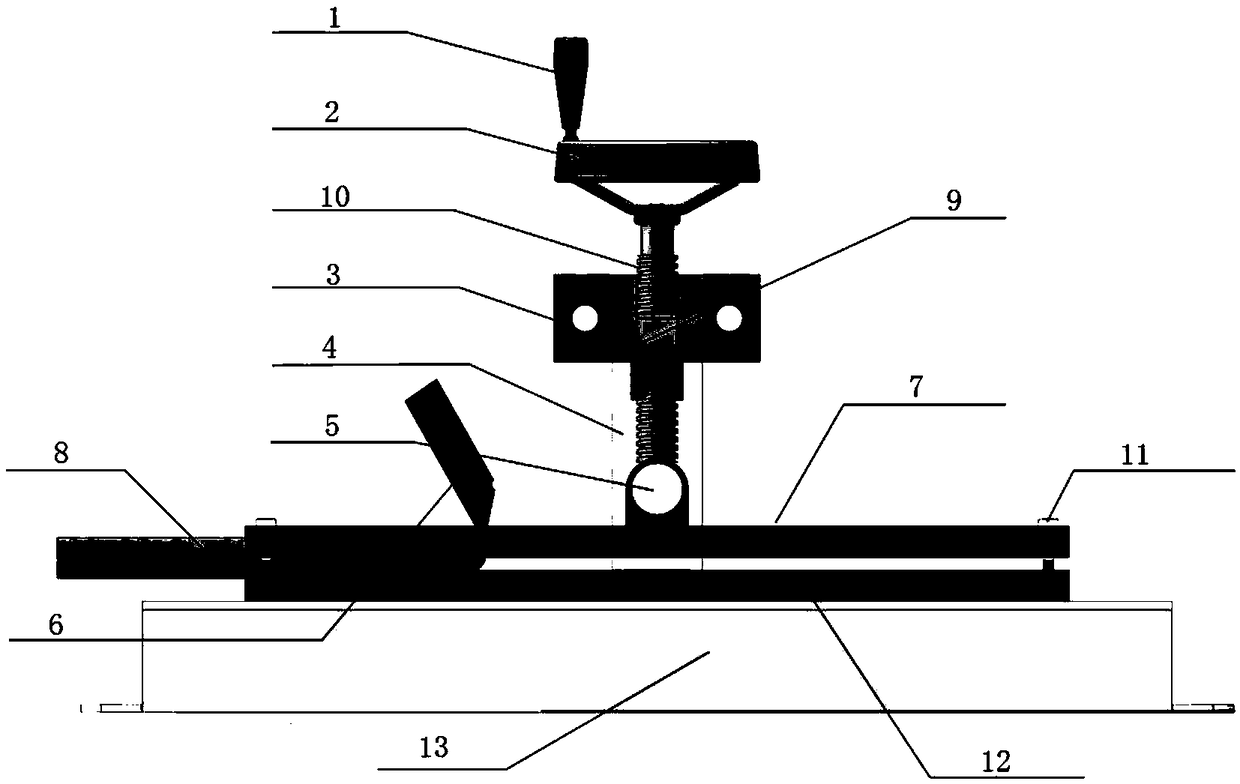

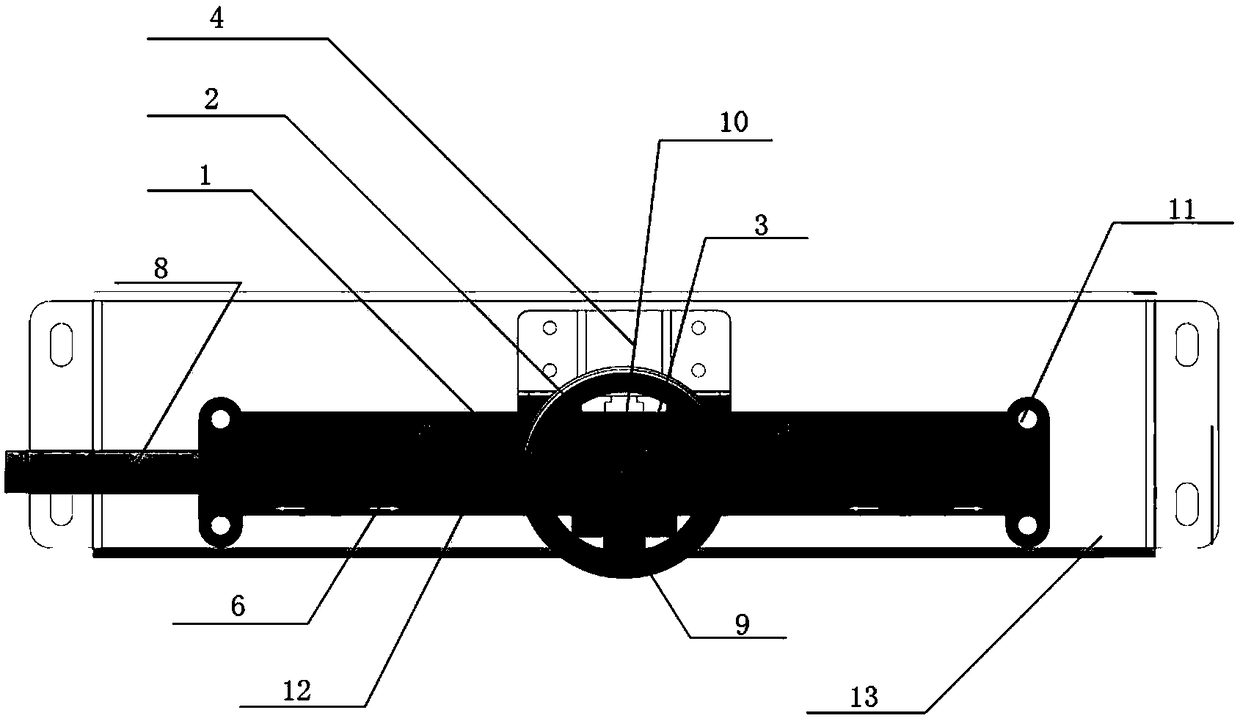

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

[0025] refer to Figure 1 to Figure 4 , the rubber strip sealing ring manufacturing tool of the present invention comprises a base 13, a static pressure block 12, a dynamic pressure block 7, a bracket fixing seat 4, a fixing bracket 3, a quick lock nut 9, a screw rod 10, a guide bolt 11, a cutting blade 6 and super glue; the bracket fixing seat 4 and the static pressure block 12 are fixed on the base 13, the dynamic pressure block 7 is located on the static pressure block 12, the fixed bracket 3 is fixed on the top of the bracket fixing seat 4, and the upper surface of the dynamic pressure block 7 is set There are screw bolts 5 and fast lock nuts 9 fixed on the fixed bracket 3, the lower end of the screw rod 10 passes through the quick lock nuts 9 and is flexibly connected with the screw bolts 5, and the guide bolts 11 pass through the dynamic pressure block 7 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com