Blade type design method for axial-flow type turbine large and small blade combined blade lattice

A technology of blade combination and design method, which is applied in the directions of blade supporting elements, mechanical equipment, stators, etc., can solve the problems of difficult parameterization of blade shape data, poor stability of blade aerodynamic performance, and weak correlation of blade design. Achieve the effect of low dependence on personal experience, good stability of aerodynamic performance, and small workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, technical solutions and advantages of the implementation of the present application clearer, the technical solutions in the embodiments of the present application will be described in more detail below in conjunction with the drawings in the embodiments of the present application.

[0038] This application provides a method for designing an axial-flow turbine blade combined cascade blade type, such as Figure 4 , Including the following steps:

[0039] Step 1: Select the number of blades

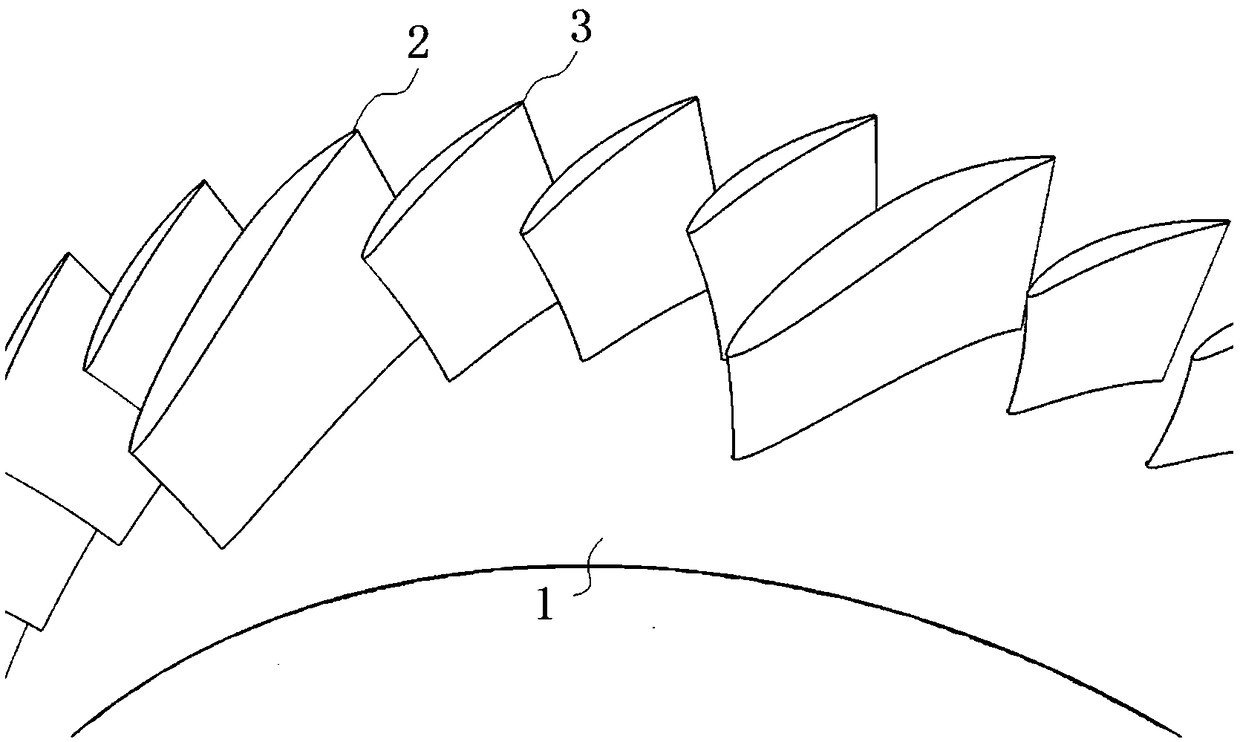

[0040] Determine the number N of large blades uniformly distributed along the circumferential direction, and evenly place the same number of small blades m between every two large blades to determine the total number of blades m·N+N.

[0041] This step is the same as the prior art solution.

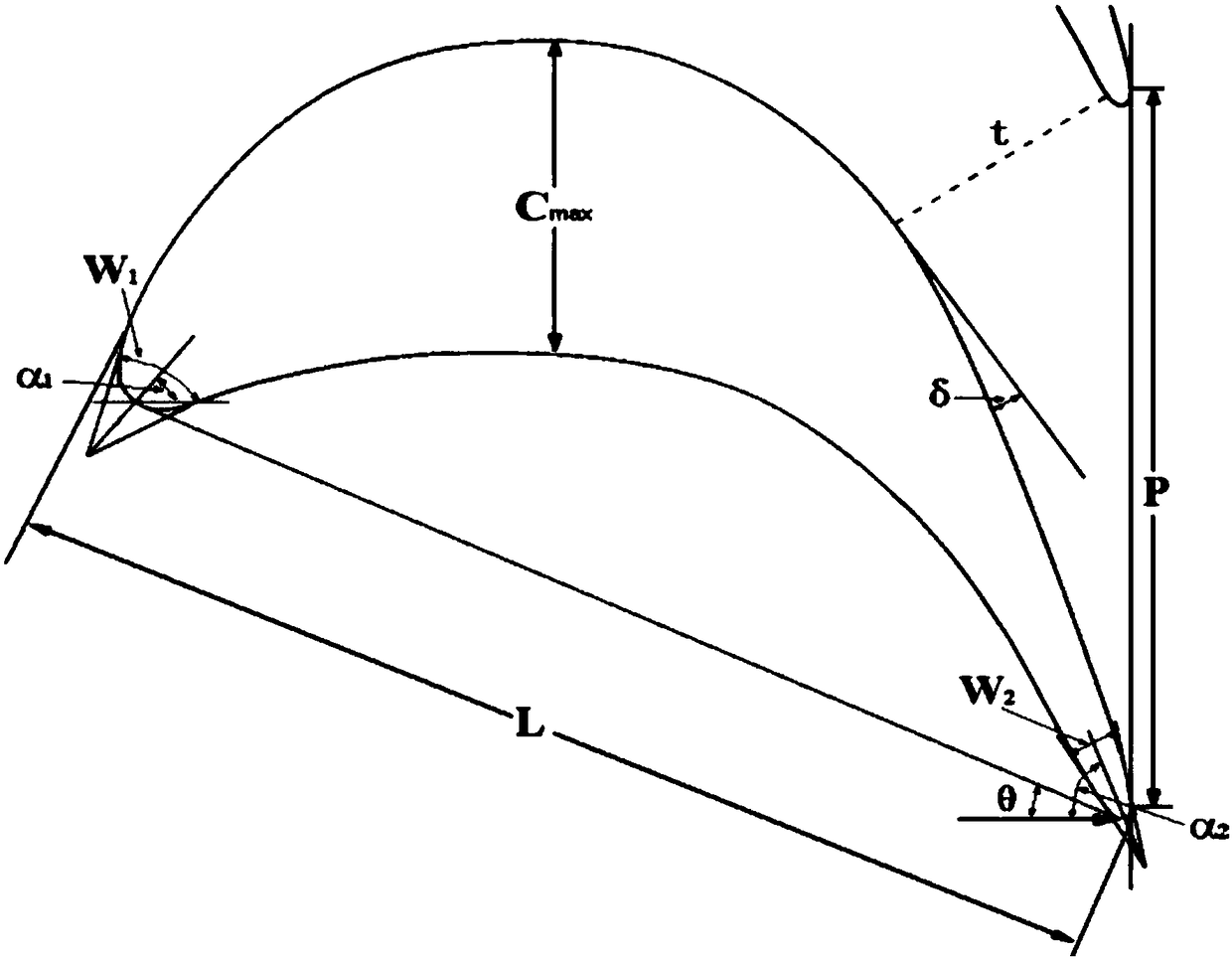

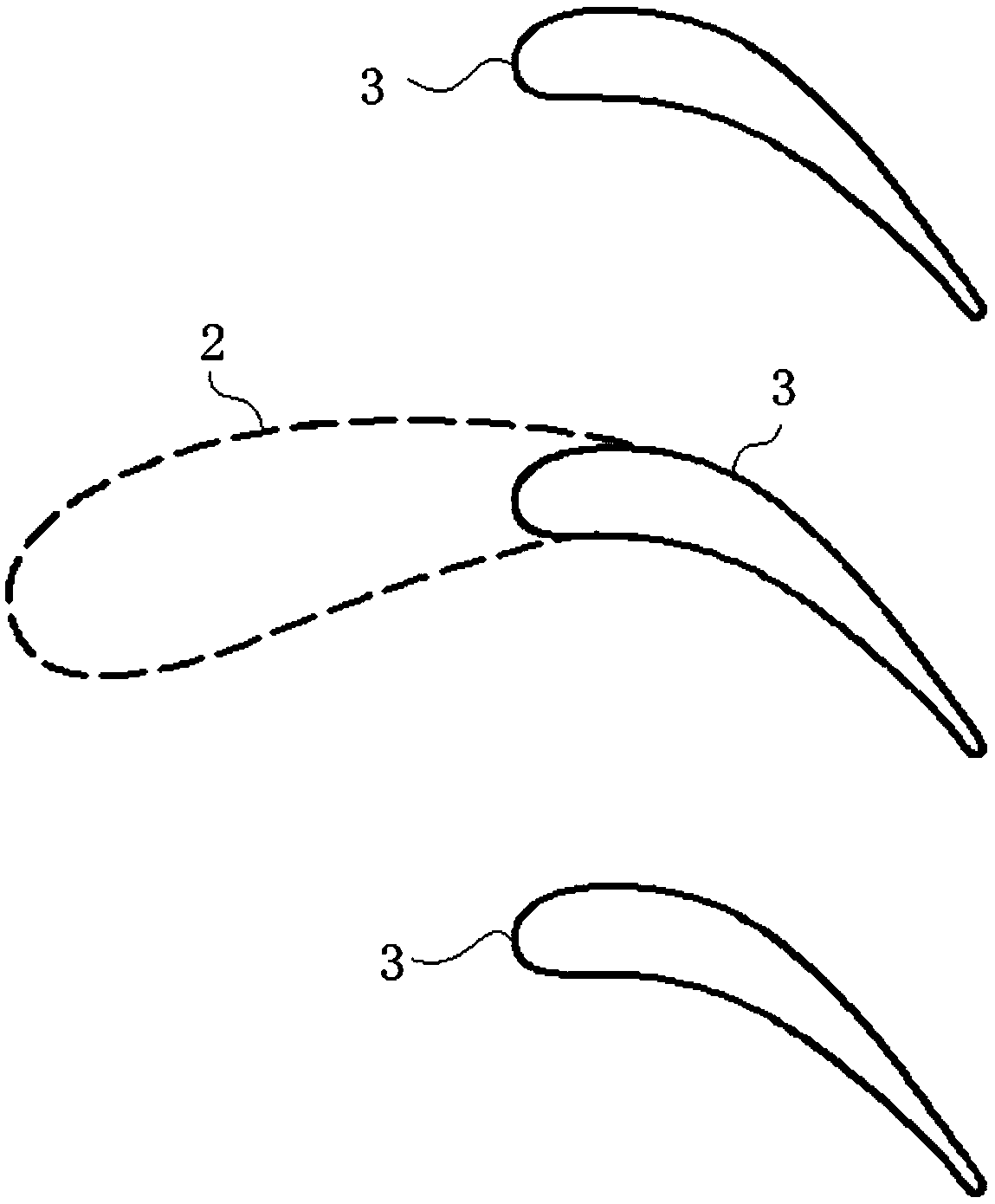

[0042] Step two, complete the parameterized design of large blades

[0043] Starting from this step, it is different from the existing technical solution. In this step, it is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com