Steel tube bundle combined shear wall BIM parametric modeling method and device based on Tekla platform

A combined shear wall and parametric modeling technology, applied in design optimization/simulation, special data processing applications, geometric CAD, etc., can solve the problems of low modeling parametric degree, heavy repetitive workload, and low efficiency. Achieve high degree of parameterization, reduce repetitive work, and save engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

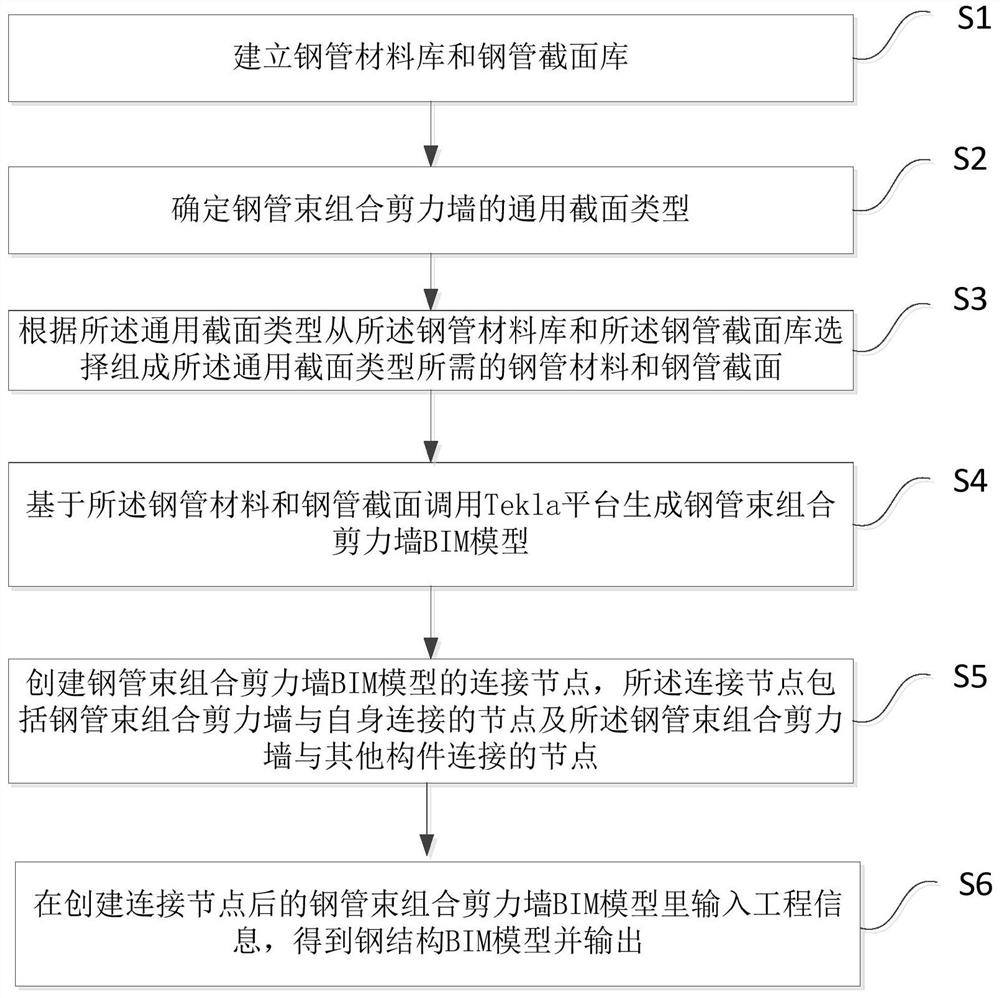

[0058] This embodiment implements a BIM parametric modeling method for steel pipe bundle composite shear walls based on the Tekla platform, such as figure 1 As shown, the details are as follows:

[0059] S1. Establish a steel pipe material library and a steel pipe section library;

[0060] S2, determine the common section type of steel tube bundle composite shear wall;

[0061] S3. Select steel pipe materials and steel pipe sections required to form the general cross-section type from the steel pipe material library and the steel pipe cross-section library according to the general cross-section type;

[0062] S4, calling the Tekla platform based on the steel pipe material and the steel pipe section to generate a BIM model of the steel pipe bundle combined shear wall;

[0063] S5, create the connection node of steel pipe bundle combined shear wall BIM model, described connection node comprises the node that steel pipe bundle combined shear wall connects with itself and the no...

Embodiment 2

[0076] This embodiment implements a BIM parametric modeling method for a steel pipe bundle composite shear wall based on the Tekla platform, and the steps are described in detail as follows.

[0077] The first step is to establish steel pipe material library and steel pipe section library.

[0078] The second step is to determine the common section type of steel tube bundle composite shear wall.

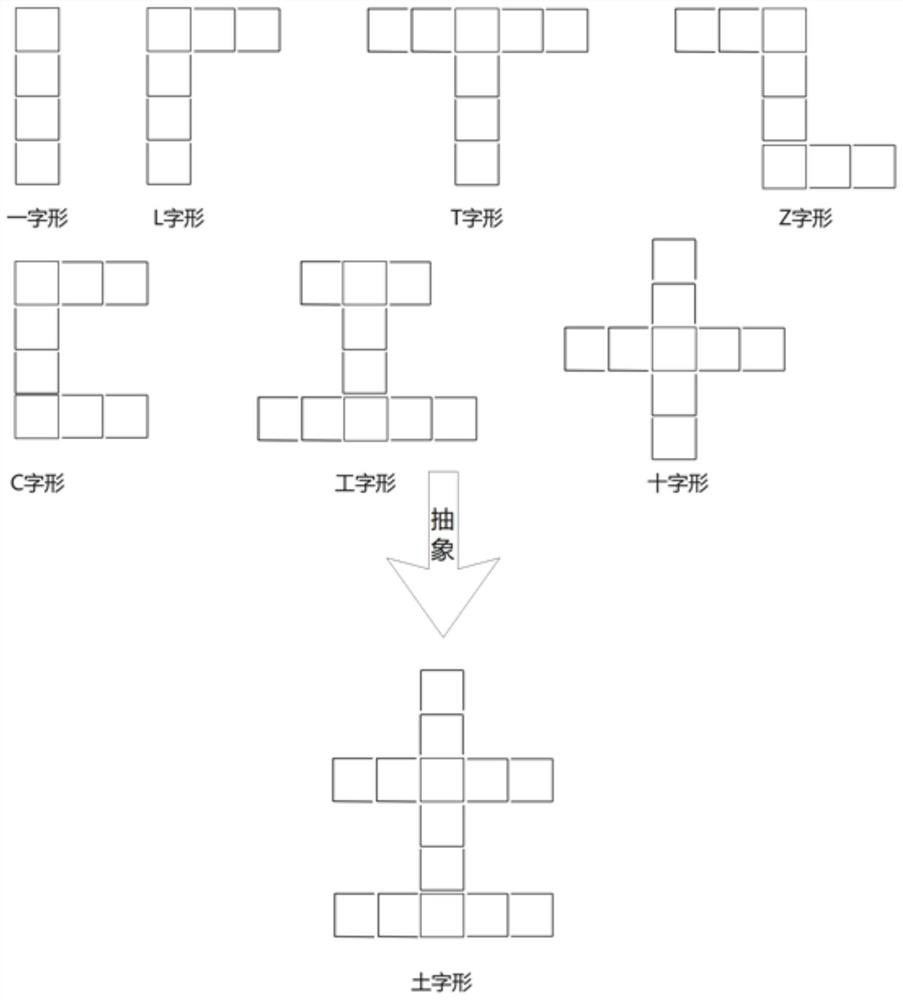

[0079] figure 2 In order to determine the schematic diagram of the general section type of steel tube bundle composite shear wall, specifically, as figure 2 As shown, it is determined that the general section type of the combined steel pipe bundle shear wall is earth-shaped, including: analyzing the commonly used steel pipe bundle combined shear wall section types, and the commonly used steel pipe bundle combined shear wall section types include straight, L-shaped , T-shape, Z-shape, C-shape, I-shape, and cross-shape (the "shape" can also be replaced with "shape"); the commonly u...

Embodiment 3

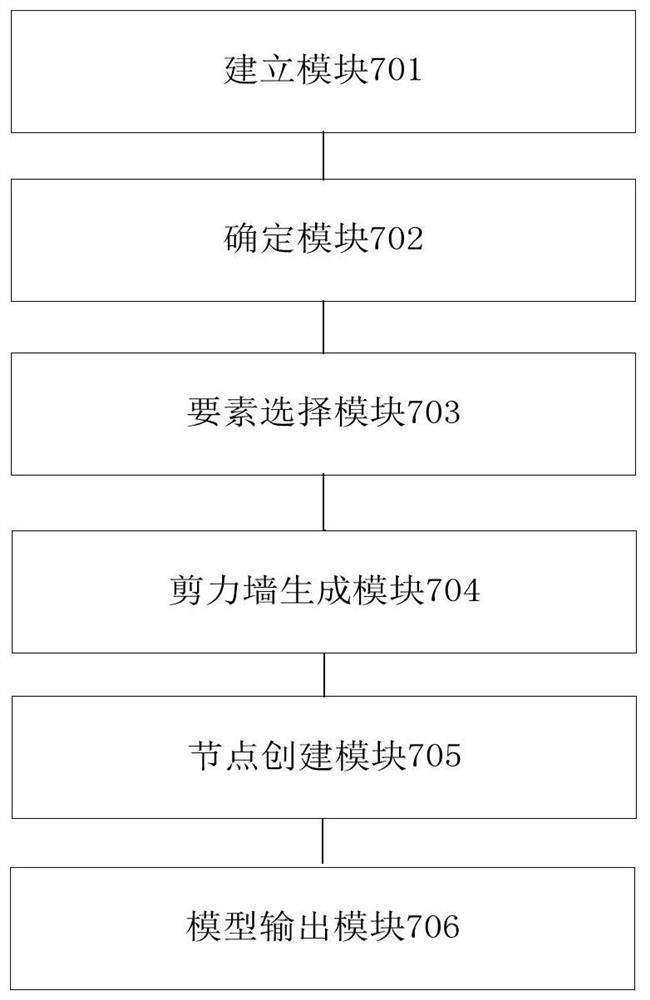

[0091] This embodiment provides a BIM parametric modeling device for steel pipe bundle composite shear walls based on the Tekla platform, such as image 3 shown, including:

[0092] Build module 701, used to build steel pipe material library and steel pipe section library;

[0093] Determining module 702, used to determine the common section type of steel tube bundle composite shear wall;

[0094] An element selection module 703, configured to select a corresponding steel pipe material and steel pipe section from the steel pipe material library and the steel pipe section library according to the general section type;

[0095] The shear wall generation module 704 is used to call the Tekla platform based on the steel pipe material and the steel pipe section to generate the steel bundle combined shear wall BIM model;

[0096] The node creation module 705 is used to create the connection nodes of the steel pipe bundle combined shear wall BIM model, and the connection nodes inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com