A method for building a three-dimensional model of the inlet section of an inclined tube box-shaped inverted siphon with full parameters

A technology of three-dimensional model and import section, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of low degree of parameterization, single body shape, poor versatility, etc., and achieve high degree of parameterization and model modification simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples.

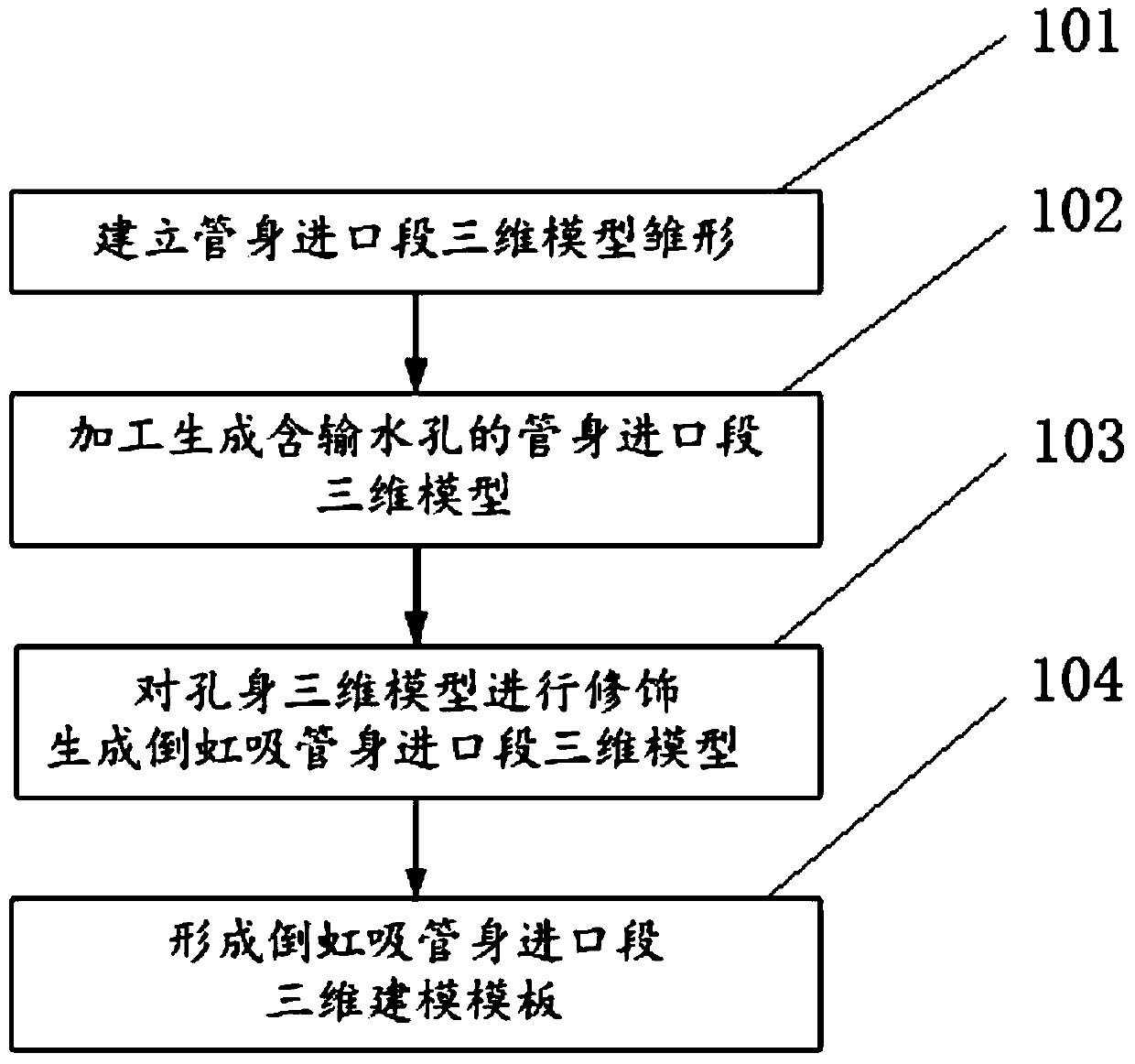

[0025] The method of establishing the three-dimensional model of the inlet section of the inclined tube box-shaped inverted siphon body with full parameters, the three-dimensional digital geometric model of the inlet section of the inverted siphon body adopts the method of gradual refinement and step-by-step refinement, such as figure 1 Shown, the flow process of modeling method of the present invention is:

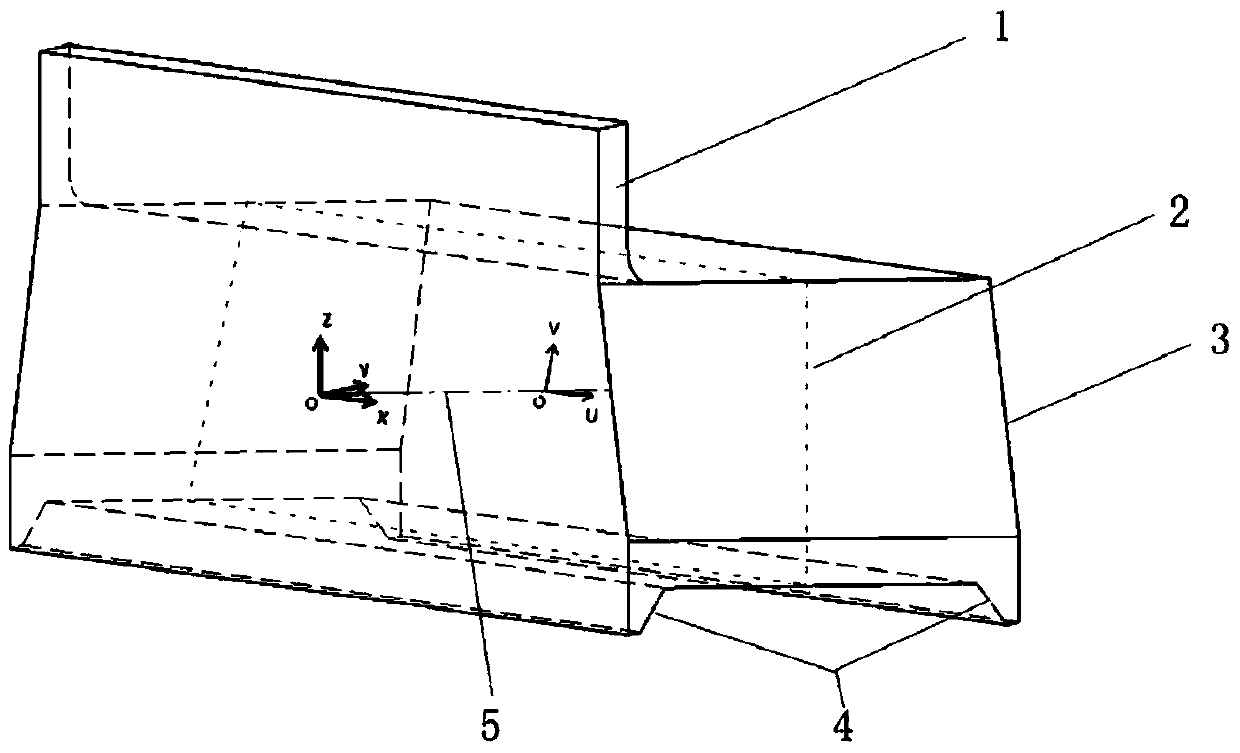

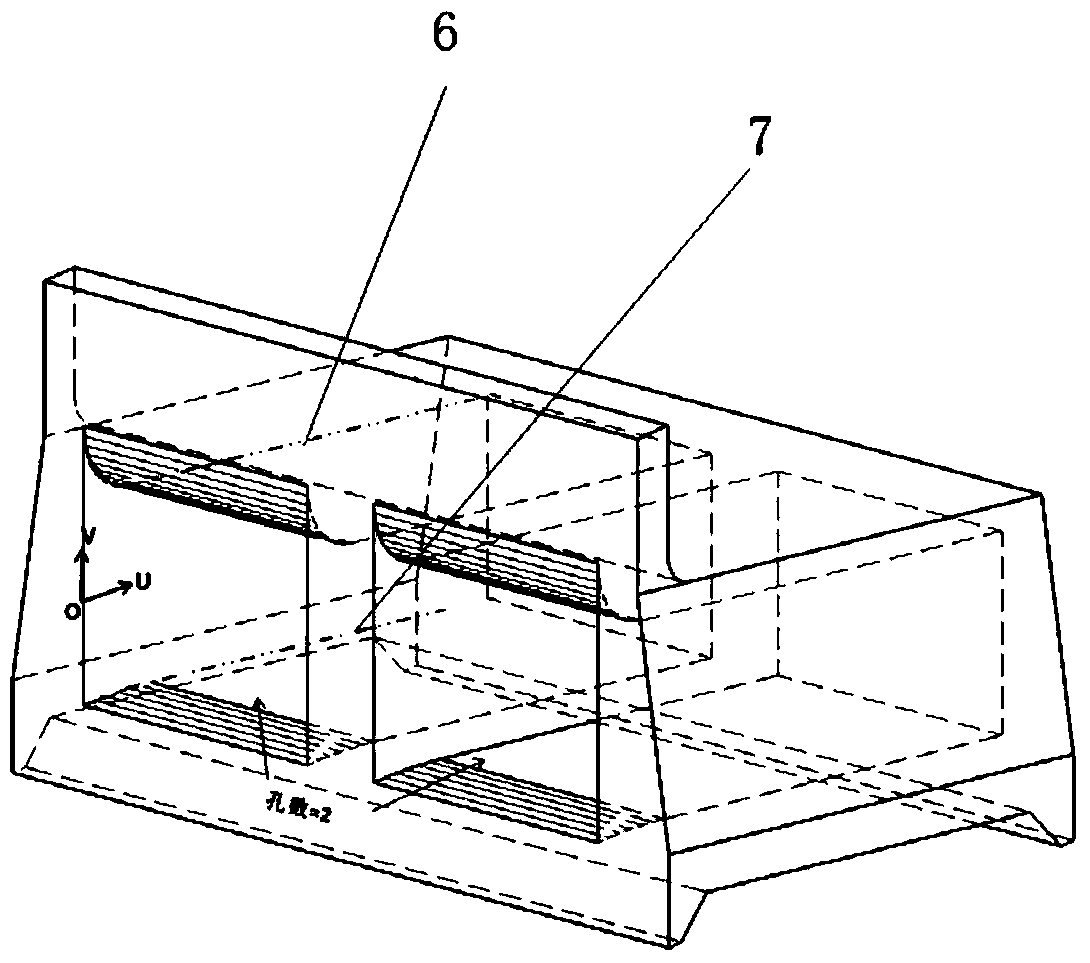

[0026] Step 101, establish the prototype of the three-dimensional model of the inlet section of the pipe body, such as figure 2 , its structure includes breast wall 1, cross-sectional outline 2, joint surface 3, anti-slip teeth 4, pipe body slope line 5, and the specific steps include:

[0027] a. Establish the overall coordinate system XYZ of the ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com