electrical connector

An electrical connector and electrical connection technology, applied in the direction of connection, components and circuits of connecting devices, can solve the problems of difficult to meet the performance requirements of transmitting high-frequency signals, difficult to achieve impedance matching, and high-frequency noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to facilitate a better understanding of the purpose, structure, features, and effects of the present invention, the present invention will now be further described in conjunction with the accompanying drawings and specific embodiments.

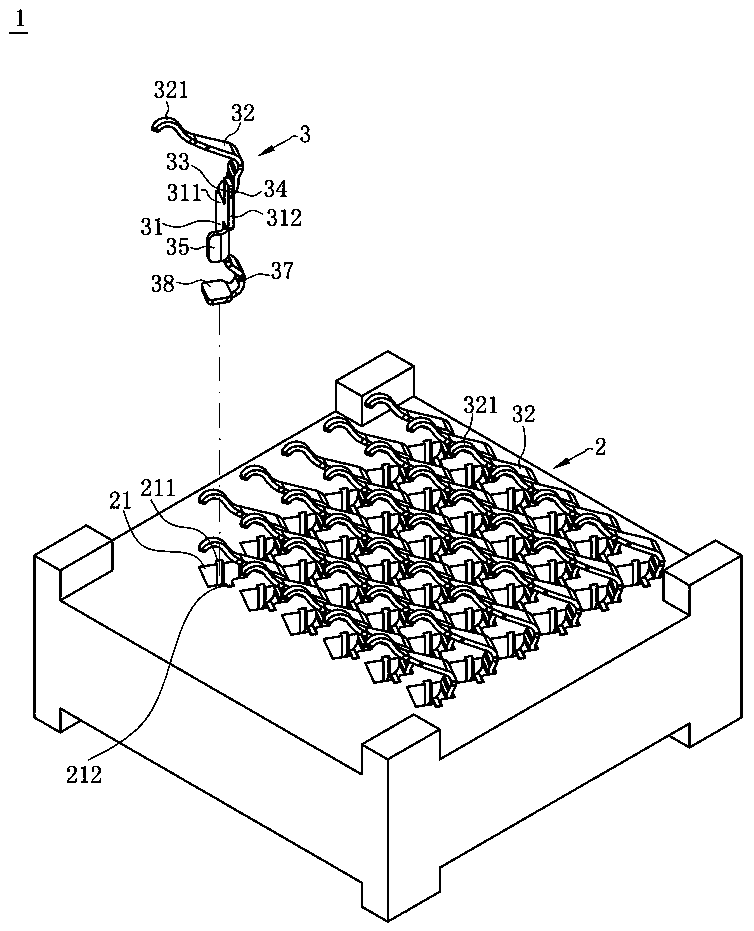

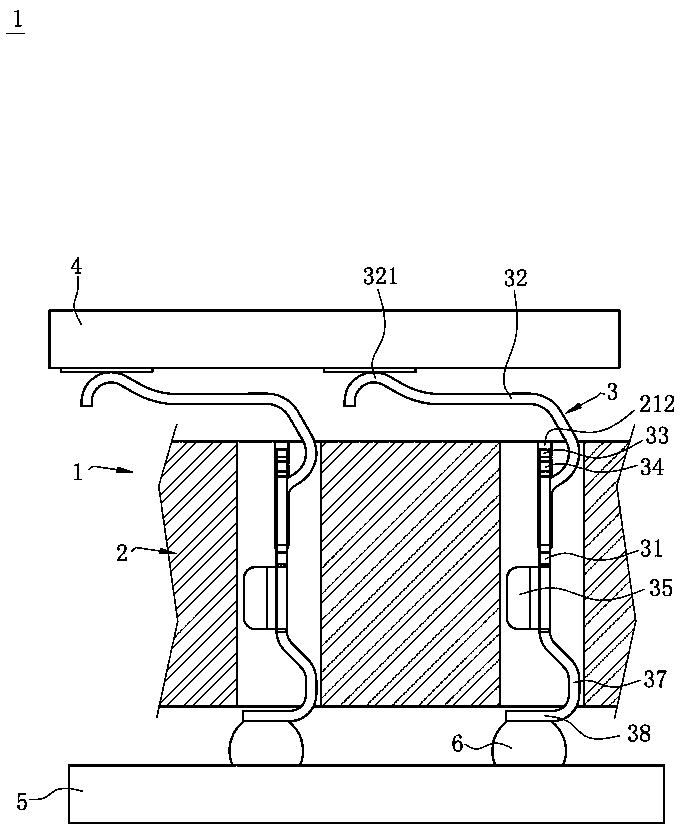

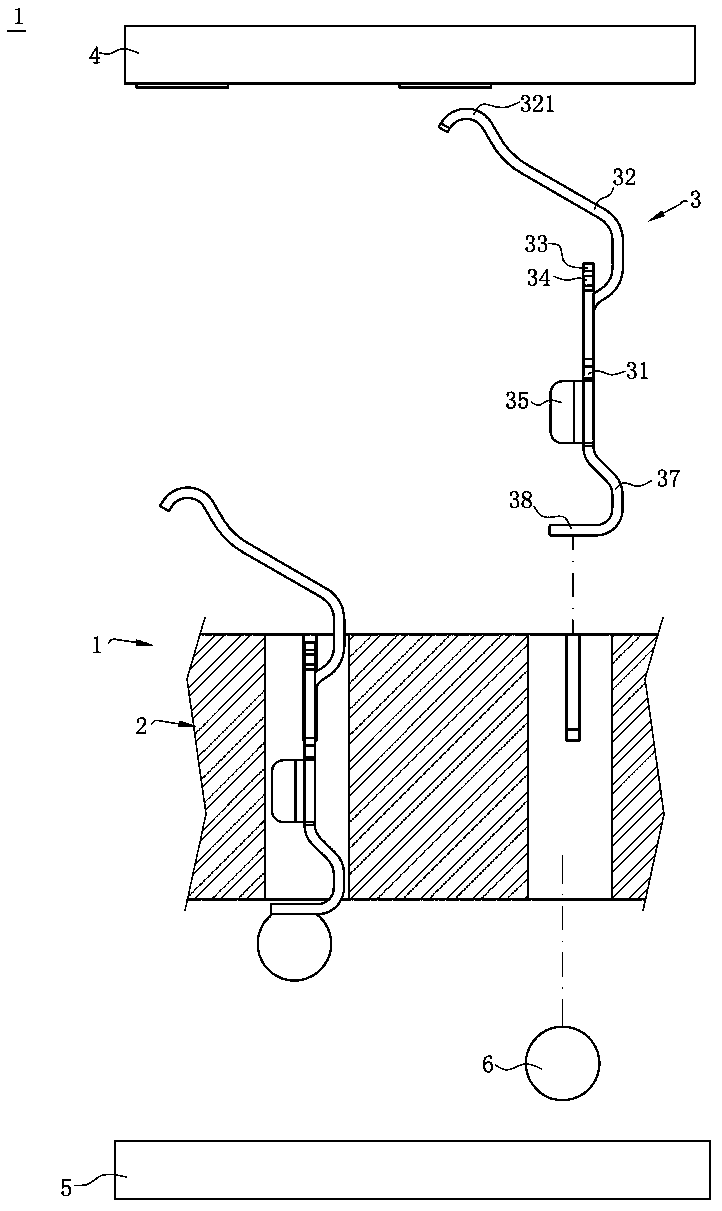

[0046] refer to Figure 1 to Figure 7 , is the first embodiment of the electrical connector 1 of the present invention, the electrical connector 1 is used to electrically connect a chip module 4 to a circuit board 5, the electrical connector 1 includes a body 2, a plurality of The conductive terminals 3 are disposed in the body 2 , the upper end of each conductive terminal 3 elastically contacts the chip module 4 , and the lower end is welded to the circuit board 5 by a solder 6 .

[0047] refer to figure 1 with Figure 5 , the body 2 is made of insulating material, and is provided with a plurality of receiving grooves 21 arranged in a matrix and penetrating the body 2 up and down. The receiving grooves 21 are formed by four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com