Oblique plunger type pure water hydraulic swash plate pump

A plunger type, swash plate pump technology, applied in the direction of variable displacement pump components, pumps, multi-cylinder pumps, etc., can solve the problems of easy failure of sliding bearings, poor self-priming ability, high fluid noise, etc., to improve the stability of work. The effect of improving the self-absorption capacity and reducing the flow rate of water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below will combine the appended in the partial embodiment of the present invention Figure 1~4 , the embodiments of the present invention will be described in more detail. Obviously, the described embodiments are only a part of all embodiments of the present invention. Other embodiments obtained directly or associatively from the disclosure of the present invention by persons of ordinary skill in the art without creative work, all belong to the protection scope of the present invention.

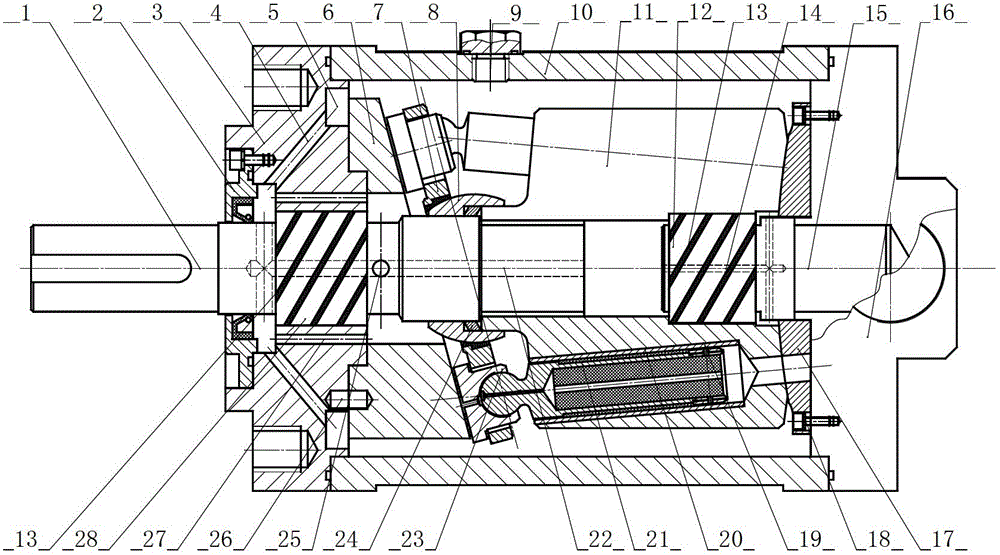

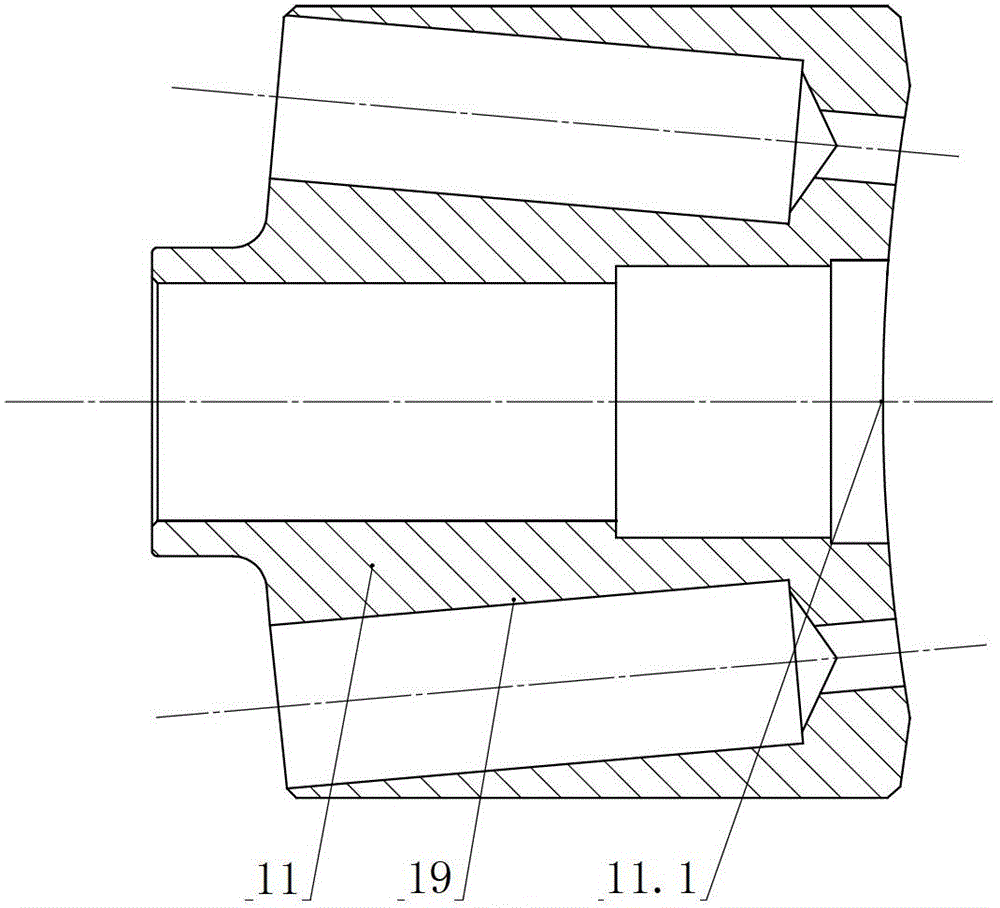

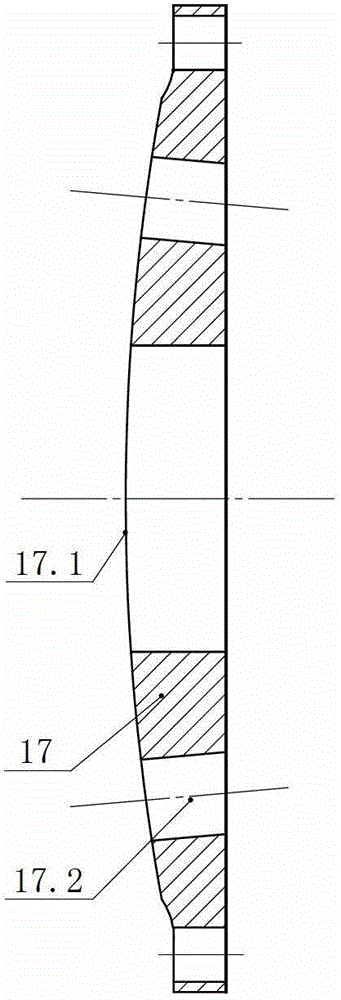

[0037] An embodiment of the present invention provides an inclined plunger type pure water hydraulic swash plate pump. Such as figure 1 As shown, the front end cover 3, the housing 10, and the rear end cover 16 are connected as one; the main shaft 1 is connected with the tapered cylinder 11 to form a main shaft-tapered cylinder assembly; the front sliding bearing 28 is embedded in the front end cover 3, and The main shaft 1 is connected; the rear support shaft 15 is in interference co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com