Scald and electricity leakage preventing electric kettle

An electric water boiler and anti-leakage technology, which is applied to boiling water appliances, cooking utensils, household appliances, etc., can solve the problems of easy scalding of hands and easy leakage of electricity caused by switches, so as to enhance ventilation performance, prevent moisture leakage, and keep the bottom of the pot clean. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

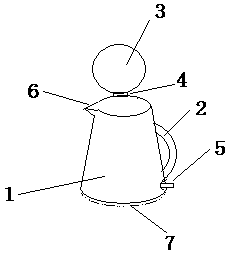

[0018] exist figure 1 In the shown first embodiment, the volume of the kettle body of the electric water boiler is 2 liters, the diameter of the kettle lid is 120 mm, and the electric power is 1500 watts. The electric switch is located under the handle, and the spout is located at the opposite top of the handle.

[0019] The position of the hinge axis of the pot lid, if the lid is compared to the dial of a clock, and the spout is regarded as the 12 o'clock position, then the top of the pot handle is at the 6 o'clock position, and the lid hinge axis is at the 3 o'clock position. The lid lock is at the 9 o'clock position.

[0020] The bottom edge of the kettle body has a diameter of 150mm and a edge width of 3mm. In order to enhance the ventilation performance of the water-stop edge of the pot bottom, the entire circumference of the bottom edge of the pot body protrudes downwards, and the lower edge of the protruding circular edge presents an uneven structure including waves, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com