Tandem mill board and base adjusting method thereof

A continuous rolling mill, rolling mill technology, applied in the direction of metal rolling mill stand, metal rolling stand, metal rolling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is further illustrated below by specific examples.

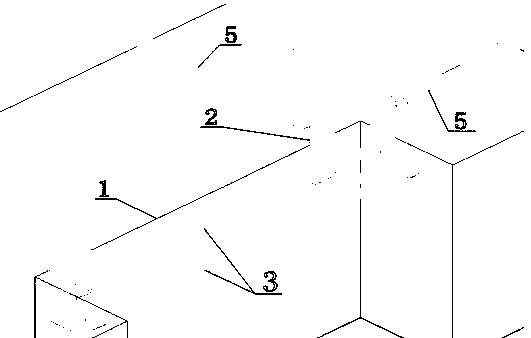

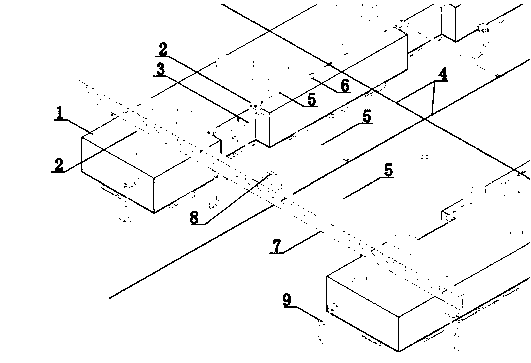

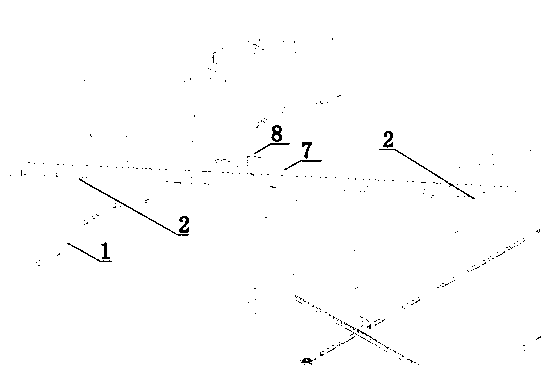

[0033] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] A method for adjusting archways and bases of continuous rolling mills using contour blocks, including

[0035] Step 1, Equal height block 2 selection:

[0036] Select the equal height block 2 to be used for erecting the level ruler and use in conjunction with the inner diameter micrometer. 10-20 blocks of two types of equal height blocks are purchased and processed to facilitate the simultaneous adjustment of the base of the multi-frame archway. Before using the contour block 2, use an outer micrometer with an accuracy level of 0.01mm to measure the thickness of each part of the single contour block 2 and the stacked thickness of multiple blocks. The contour block 2 used for erecting the ruler is 20mm wide x 10mm thick x 150mm long, and the contour block 2 used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com