Intelligent planning method for three-coordinate detection point of complex curved surface component

A complex curved surface, intelligent planning technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of wasting effective online working time of testing instruments, not being able to meet the diversification of enterprises well, and the way of testing point planning is not flexible, etc., to achieve increased Effective online working time, reducing human-computer interaction operations, and realizing the effect of intelligent generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

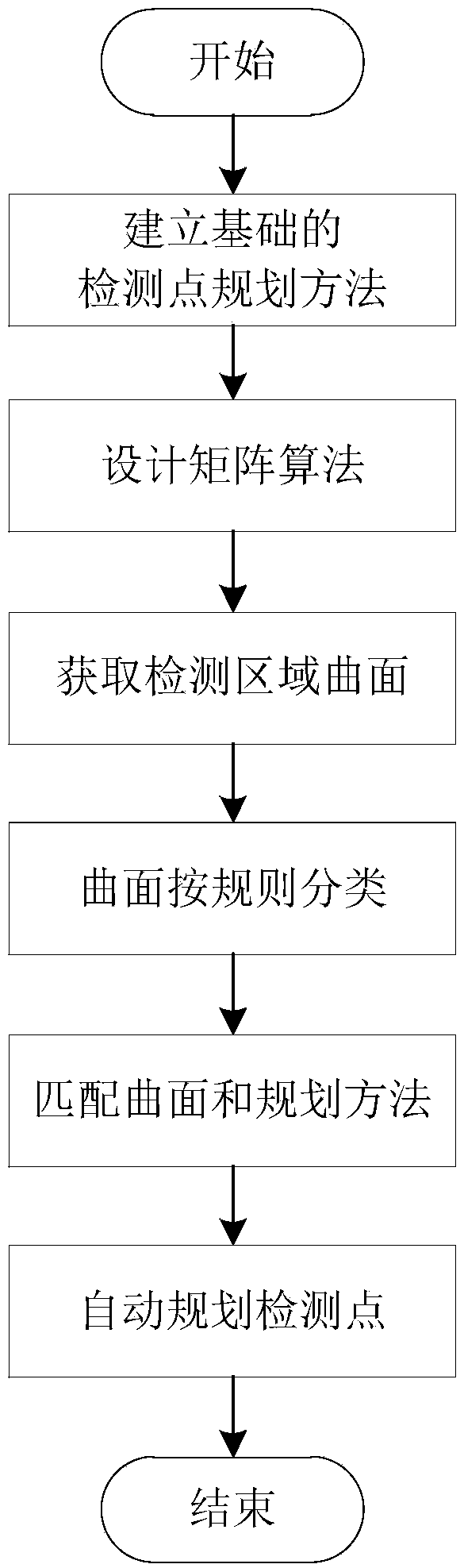

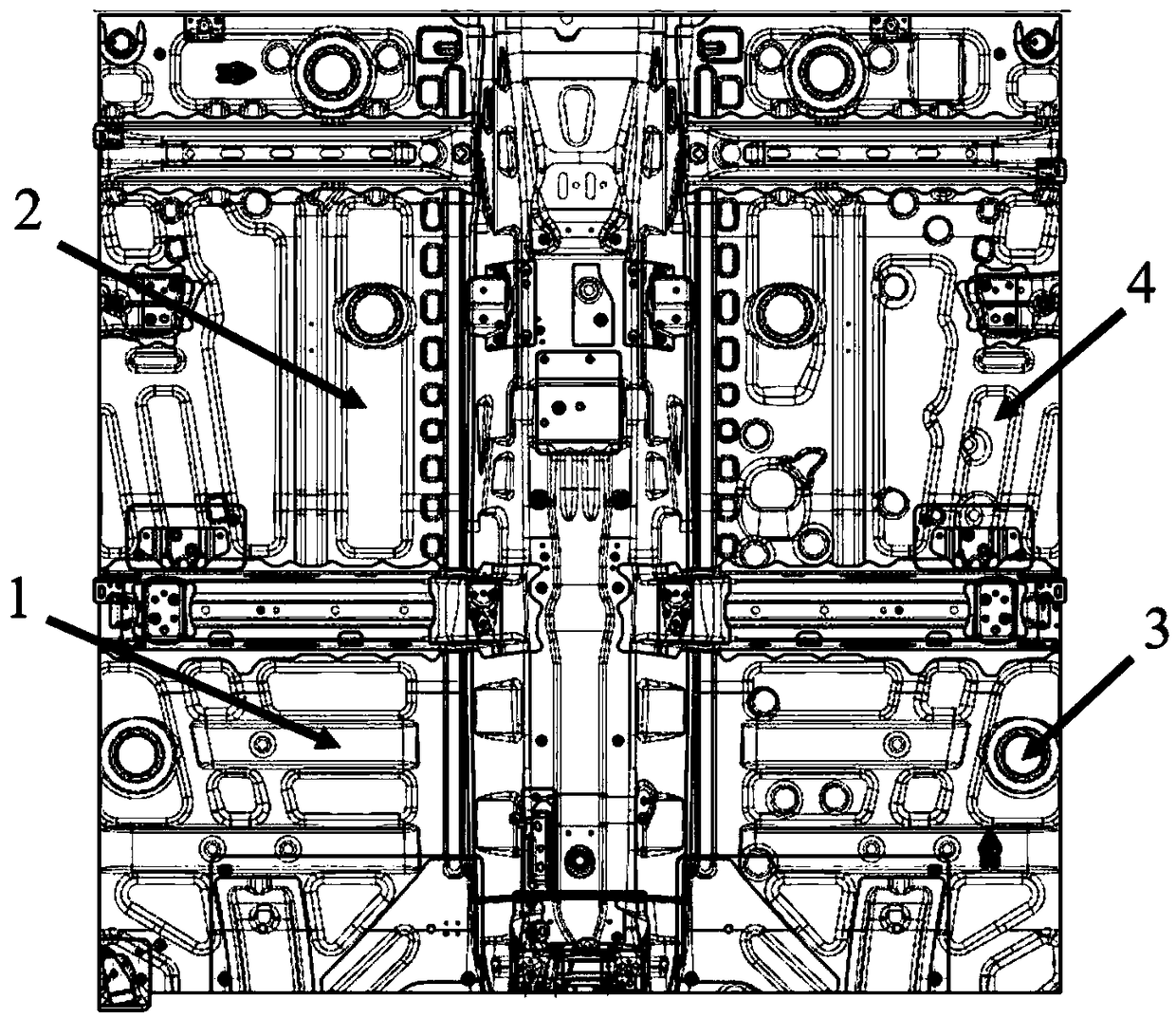

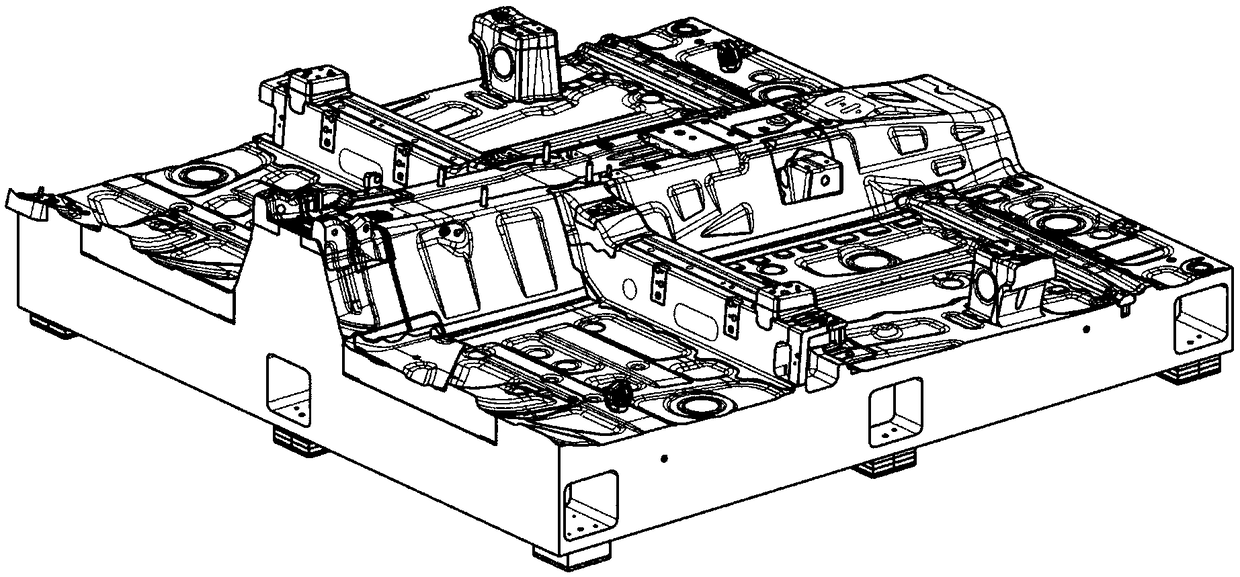

[0040] The present invention proposes an intelligent planning method for three-coordinate detection points of complex curved surface parts. The general steps of the method are as follows:

[0041] 1. A method for intelligent planning of three-coordinate detection points of complex curved surface parts, characterized in that, comprising the following steps:

[0042] Step 1: Establish several basic detection point planning forms, offset the boundary of the surface on the surface inward, and plan detection points on the generated offset curve according to the arc length of the curve; construct U and V direction parameter lines on the surface , uniformly plan the detection points in the direction of the U and V parameter lines; construct the center line of the surface, and ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com