A dangerous gas monitoring method using radioactive tracer

A technology of radioactive tracers and dangerous gases, applied in separation methods, chemical instruments and methods, and analysis of gas mixtures, etc., can solve the problems of easy blockage of gas outlets and low dust filtration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A dangerous gas monitoring method using a radioactive tracer, comprising the steps of:

[0032] 1) Select water-insoluble radioactive substance solid micropowder as the tracer;

[0033] 2) The tracer is mixed and prepared with the dangerous gas;

[0034] 3) Determine the concentration of the leaked gas by the intensity of the radioactive material.

[0035] The invention mixes radioactive material solid micropowder with dangerous gas, controls the mixing ratio, and converts the leakage concentration according to the mixing ratio of dangerous gas and dangerous gas when the dangerous gas leaks, so that the data analysis and test are accurate, and the addition of radioactive material solid micropowder has no effect on dangerous gas. The fluidity of the liquid plays a role in reducing the floating height and diffusion speed of dangerous gases, and can be judged by the concentration of radioactive substances in the first time of leakage, providing a variety of ways to monito...

Embodiment 2

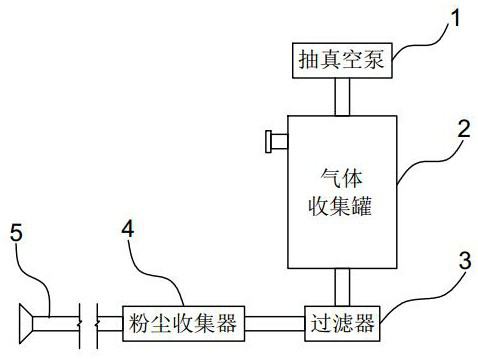

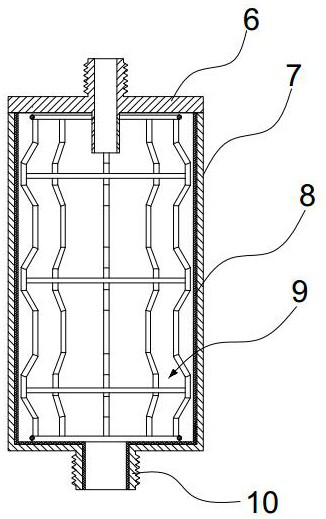

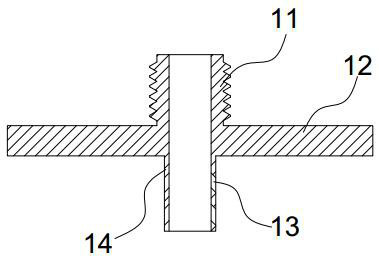

[0039] like Figure 1-5 As shown, the device for collecting solid micropowder gas containing radioactive substances includes a dust collector 4 connected to a collection pipe 5 at the inlet end, and a filter 3 connected to the outlet end of the dust collector 4, and the filter 3 is connected to the gas collection tank 2, and the gas The collection tank 2 is connected with a vacuum pump 1 . After the leakage of dangerous gas, it is not only necessary to monitor the leakage concentration to judge the degree of danger, but also to carry out emergency treatment on the leakage of dangerous gas to prevent major safety accidents. There are also certain safety hazards. When dealing with leaked gas, it is necessary to treat radioactive solid micropowder and dangerous gas together. In order to ensure the collection amount in the process of leaking dangerous gas, it is necessary to discharge the gas in the gas collection pipe 2 by using the vacuum pump 1. When the internal gas is exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com