Experimental device and method for simulating progressive failure of aeolian sand stratum in tunnel construction

A technology of progressive failure and experimental device, applied in the field of tunnel and underground engineering, which can solve the problems of low water content, loose structure, poor self-stabilizing ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

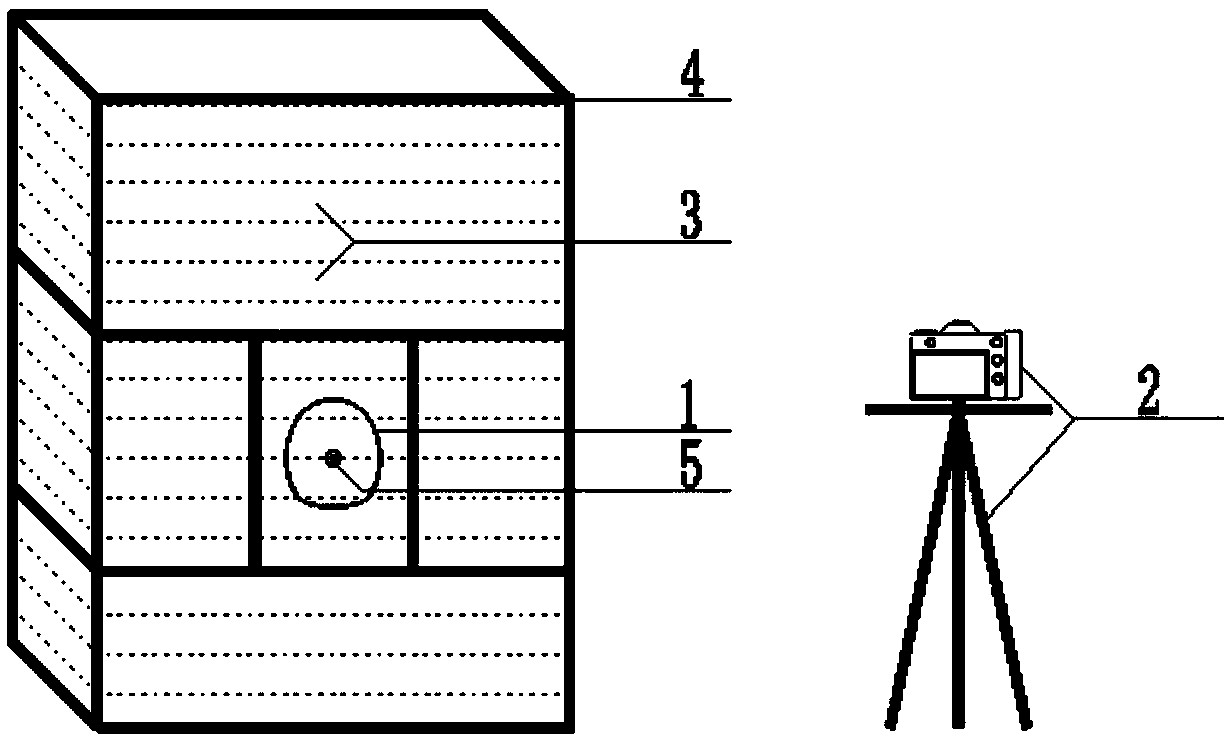

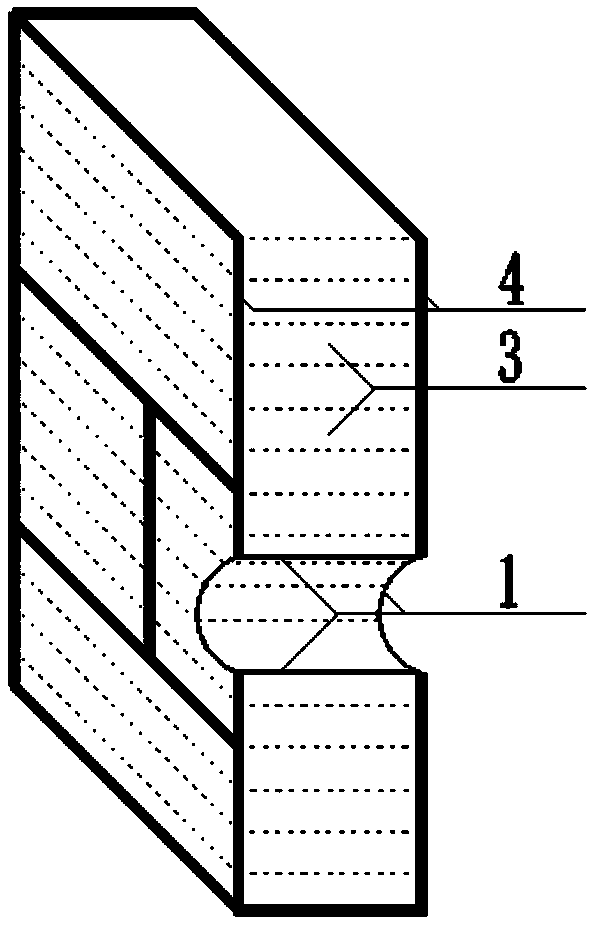

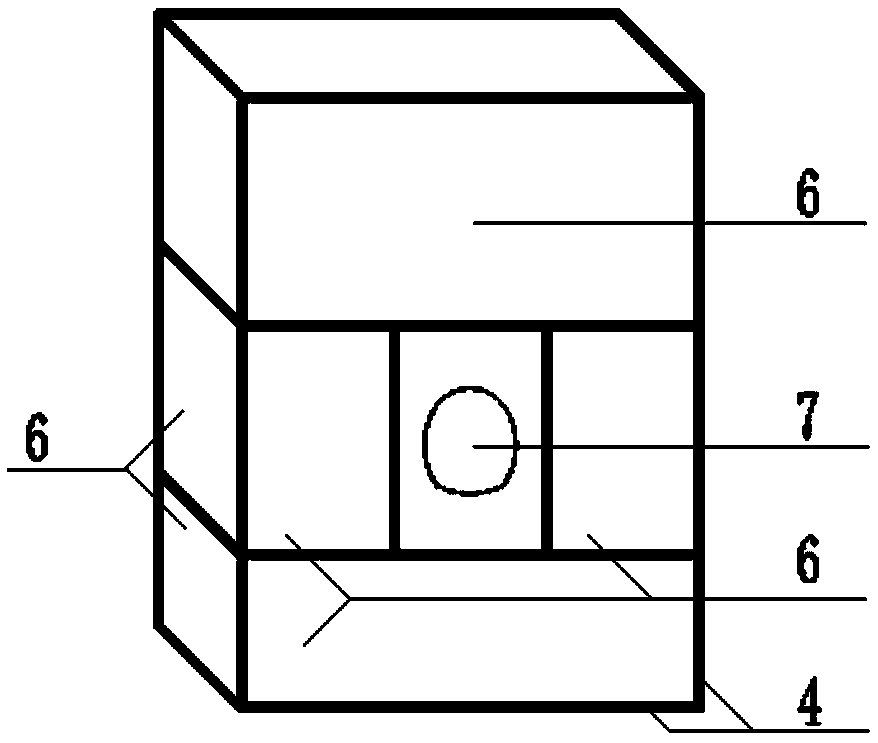

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The experimental device of the present invention is used to study the engineering characteristics of aeolian sand. In the model experiment process, the air model with the same size as the model tunnel is pre-customized according to the tunnel size and can be recharged and deflated. The air model can bear a certain range. rock pressure and no obvious deformation, and can also quickly deflate, which is used to simulate the excavation of the surrounding rock of the tunnel; using a SLR camera, it can take 8 high-definition pictures per second during the change of the surrounding rock of the model. The sequence can completely observe the deformation process of the simulated surrounding rock; the model material is dyed with colored dyes, and the most obvious and basic change law and the model material before and after the surrounding rock chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com